Fastener Manufacturer – Bespoke Bar-Turned Nuts UK

If you can't get through on the mainline please call 07967 68 82 24 Read More

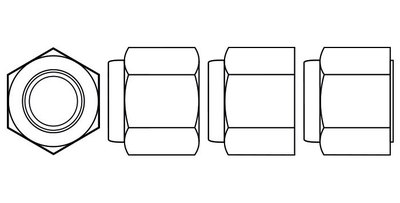

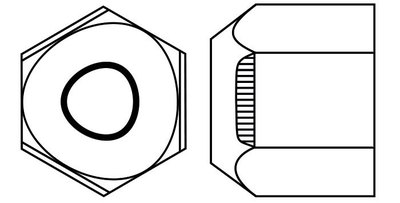

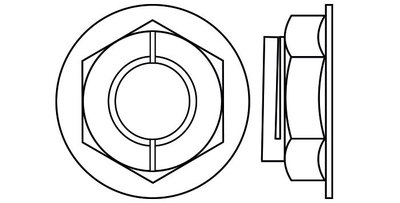

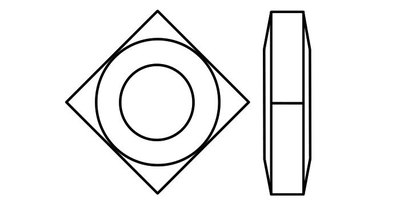

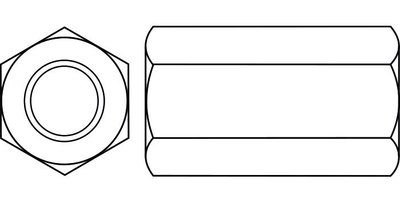

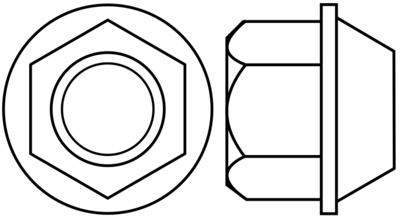

Trojan Special Fasteners Ltd is an ISO 9001:2015 certified precision fastener manufacturer based in Birmingham, with over 31 years of experience in bespoke nut manufacturing. We specialise in bar-turned internally threaded fasteners including hexagon nuts, square nuts, castle nuts, connector nuts, and prevailing torque locking nuts in standard and custom sizes.

We're experts at turning bright bar into precision parts, quickly and efficiently, ensuring that our customers receive high-quality products at competitive prices. All of our fasteners conform to BS, DIN, ISO, UN and ANSI standards. Whether you need a single prototype or production quantities in the thousands, we've got you covered.

Our state-of-the-art CNC turning and polygon turning capabilities enable us to manufacture nuts from M3 to M52 in metric sizes, and from 1/4" to 2.1/4" in imperial and unified sizes, using a comprehensive range of materials including steel, stainless steel, brass, bronze, aluminium, and other alloys.

Why Use Trojan Special Fasteners for Your Bespoke Fastener Manufacturing Needs?

If you're in need of custom fasteners for your business, you want to work with a manufacturer who has the expertise, experience, and commitment to quality that you require. Trojan Special Fasteners Ltd stands out in this field, offering a range of benefits and advantages that make us the right choice for your needs.

Expertise and Experience in Fastener Manufacturing

With over 31 years of experience in the industry, Trojan Special Fasteners Ltd has developed a deep understanding of customer needs and the challenges of fastener manufacturing. Our team of experts has the knowledge and skills needed to deliver fasteners that meet the most demanding specifications and are designed for reliable performance in a variety of applications.

Whether you're looking for fasteners for construction, engineering, aerospace, marine, railway, or another sector, our team will work with you to understand your needs and create a solution that meets your requirements. Our extensive knowledge of materials and manufacturing processes allows us to create fasteners that are not only functional, but also durable and long-lasting.

What sets our experience apart:

- Over 31 years manufacturing precision fasteners in Birmingham

- Thousands of different nut specifications produced

- Experience with exotic and challenging materials

- Understanding of industry-specific requirements (railway, aerospace, marine, etc.)

- Problem-solving expertise for unusual or non-standard requirements

- Technical support throughout design and manufacturing process

Commitment to Quality – ISO 9001:2015 Certified

At Trojan Special Fasteners Ltd, we are committed to delivering the highest quality products and services to our customers. Our team is dedicated to ensuring that every fastener we manufacture meets or exceeds industry standards and customer expectations. We use state-of-the-art equipment and processes, and we carefully inspect every product to ensure it meets our strict quality standards.

We are accredited to ISO 9001:2015, which is an internationally recognised standard for quality management systems. This means that we have a documented quality management system in place, and that we are committed to continuous improvement. Our commitment to quality is reflected in everything we do, from the materials we use to the way we interact with our customers.

Our quality assurance includes:

- ISO 9001:2015 certified quality management system

- First-off inspection and in-process quality checks

- Thread gauge verification (GO/NO-GO gauges)

- Dimensional inspection to customer specifications

- Material traceability throughout production

- Material certificates available (EN 10204 3.1)

- Heat treatment certificates where applicable

- Plating and coating certificates

- Certificates of conformity

- Initial Sample Inspection Reports

Customisation and Flexibility – We Specialise in Special

We understand that every customer has unique requirements, which is why we offer bespoke fastener manufacturing services. Whether you need fasteners in a specific material, with specific coatings, in a specific shape or size, or with custom features, we can help. Our team of experts will work with you to create a solution that meets your needs.

We have the capabilities to manufacture fasteners in small or large quantities, to tight tolerances, and with quick turnaround times. We are also flexible in our approach, and we understand that your needs may change over time. Our team is always ready to work with you to adjust your fastener specifications as your needs evolve, and we are committed to delivering the best possible service, no matter what.

Custom capabilities include:

- Mixed threads: Different thread types or sizes on each end (e.g., M12 one end, 1/2" UNC the other)

- Non-standard sizes: Non-preferred metric sizes, intermediate sizes, special dimensions

- Custom thread forms: Left-hand threads, multi-start threads, oversized threads, custom pitches

- Special features: Collars, flanges, castellations, slots, holes, spigots, domes

- Single quantities: No minimum order quantity – happy to make prototypes

- Special finishes: Any coating or plating available through our approved suppliers

- Working from samples: Send us a sample nut and we'll duplicate it

- Working from drawings: PDF, DWG, DXF, or even hand sketches

True Manufacturing Capability – Made in Birmingham

We're manufacturers, not resellers or distributors. All machining takes place in-house at our Birmingham facility, giving us complete control over quality, lead times, and specifications. This means when you order from us, you're dealing directly with the people who make your fasteners.

Our in-house capabilities:

- CNC and conventional automatic lathes for quick machine setup and part turnaround

- Polygon turning equipment (create hexagon or square from round bar)

- Comprehensive tapping capabilities (Metric, Imperial and Unified, all thread forms)

- Cross-drilling and secondary operations

- Thread distortion for prevailing torque features

- Slotting and grooving operations

- In-house inspection and quality verification

- Climate-controlled measurement room

This in-house capability means we can respond quickly to urgent requirements, accommodate design changes, and maintain consistent quality. We're not dependent on third-party suppliers or overseas manufacturers – everything is made in Birmingham.

Quick Turnaround Times Without Compromising Quality

We understand that time is often critical. Our efficient setup and experienced team allow us to offer quick turnaround times without sacrificing quality:

- Same-day quotes on most enquiries

- 3-5 working days typical lead time for standard items in common materials

- 7-10 working days for bespoke items or unusual materials

- Expedited service available for genuine urgencies

- Prototype service – fast turnaround on samples for approval before production

We pride ourselves on keeping our promises. If we quote a lead time, we deliver on it. Many customers come to us specifically because larger suppliers can't accommodate their timescales.

Competitive Pricing and Excellent Customer Service

At Trojan Special Fasteners Ltd, we are committed to delivering excellent value to our customers. We offer competitive pricing, and we are transparent about our costs and the value we provide. As a specialist manufacturer, we can often be more cost-effective than you might expect – our efficient processes and lack of middlemen mean you're not paying unnecessary markups.

We also understand the importance of excellent customer service, which is why we are dedicated to providing a high level of support and service to every customer, regardless of order size. Whether you're looking for assistance with selecting the right fasteners, need help with the manufacturing process, or have any questions or concerns, our team is always here to help.

Our customer service commitment:

- Technical support from experienced engineers

- Help with material selection and specification

- Advice on thread forms and standards

- Assistance with design optimisation

- Clear communication throughout the process

- Proactive updates on order progress

- Responsive to emails and phone calls

- Building long-term relationships, not just taking orders

We believe in building strong, long-lasting relationships with our customers, and we are committed to providing the best possible service, every time. Many of our customers have been with us for years, some even decades, because they know they can rely on us.

No Minimum Order Quantity – Prototypes to Production

Unlike many manufacturers who insist on large minimum order quantities, we're happy to manufacture:

- Single prototypes for design verification

- Small batchesfor trials or limited production

- Medium volumes for ongoing supply

- Large production runs when you scale up

Our efficient setup allows us to be economically viable at single-unit quantities whilst remaining competitive at volume. This flexibility means you can work with one supplier from concept through to mass production.

Why Trojan Special Fasteners?

- UK Manufacturing to the highest standards

- Specialists in hard to find items

- Quick deliveries

- Fully traceable manufacturing and delivery

- Fully compliant ISO 9001:2015 quality standard

- Certificates in materials, heat treatment and plating available

- Certificates of Conformity

- Reliable, professional and courteous service

- Large and hard to find nut manufacturer

Our Manufacturing Capabilities at a Glance

What We Can Manufacture

Thread Sizes

- Metric: M3, M4, M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M20, M22, M24, M25, M26, M27, M28, M30, M32, M33, M34, M35, M36, M38, M39, M40, M42, M45, M48, M50, M52 and M56 in coarse, fine, extra fine and hard to find pitches.

- Imperial and Unified: #6, #8, #10, 0BA, 1BA, 2BA, 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2", 2.1/4", 2.1/2"

- BSP, BSG, BSW, BSF, BSCy, CEI - if we can get it we can turn it.

- Non-preferred and intermediate sizes available

Thread Forms:

- Metric (ISO) – coarse and fine pitch

- Unified (UNC, UNF, UNEF)

- Whitworth (BSW, BSF, BSP)

- Stay (11 and 12tpi forms)

- BA (British Association)

- BSG, BSPP, BScy, CEI

- Custom pitches and forms

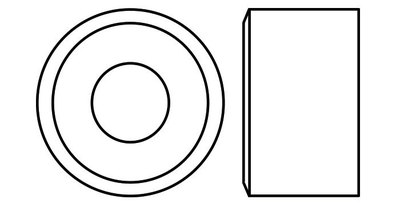

Nut Profiles:

- Hexagon (full, lock, heavy hex)

- Square

- Round/cylindrical

- Custom polygons via polygon turning

Special Features:

- Castle/slotted (2, 4, 6, 8, 12 slots)

- Nylon insert (ASME B18, B16, BS4929-1, BS4929-2, DIN 982/985/6924 type and ISO 7040/7041/10511/10512)

- All-metal prevailing torque (DIN980, ASME and other various types)

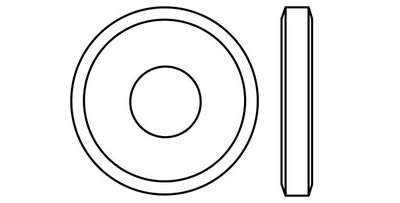

- Flanged

- Wheel Nuts

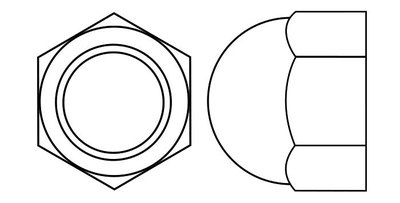

- Domed/capped

- With collars or spigots

- Mixed thread combinations

- Mixed feature combinations (for example a nylon insert flanged nut)

Materials:

- Steel: Mild steel (EN1A/EN3B), high tensile (EN8/16T, Grade 8/10/12)

- Stainless: 303, 304, 316, 410, 430

- Brass: CZ121/CW614N (free-cutting brass) and Naval Brass C46400

- Bronze: Phosphor bronze, aluminium bronze

- Aluminium: 6082, 2011

- Copper: C101

Finishes

- Self colour/oiled

- Zinc Plated (clear/yellow/black)

- Zinc-Flake Coatings (Dacromet/Geomet etc)

- Chemi-Black Phosphated

- Parkerized

- Hot-Dip Galvanized

- Nickel Plated

- Chrome Plated

- Passivated

Batch Sizes:

- 1 unit minimum (prototypes welcome)

- No maximum (we've produced tens of thousands for some customers)

Industries We Serve

Industries & Applications

Our precision fasteners are trusted by companies across diverse sectors:

Railway & Rolling Stock

Stay nuts, boiler fasteners, carriage fixtures, and rail-specific components meeting industry standards. We supply heritage railway restoration projects and modern rolling stock manufacturers.

Automotive & Motorsport

Wheel nuts, axle nuts, hub nuts, custom locknuts, and performance fasteners for road vehicles, commercial vehicles, trailers, and race applications where reliability is critical.

Aerospace & Defence

Precision fasteners to exacting tolerances using certified materials with full documentation and traceability for commercial and defence applications.

Construction & Civil Engineering

Structural nuts for steel fabrications, heavy-duty fasteners for demanding structural applications, and specialist fixings for civil engineering projects.

Marine & Offshore

Corrosion-resistant stainless steel and bronze fasteners for harsh marine environments, from pleasure craft and yachts to commercial vessels and offshore platforms.

Industrial Machinery

OEM and aftermarket fasteners for manufacturing equipment, pumps, compressors, conveyors, processing machinery, and plant installations.

Other Sectors:

Food processing, pharmaceutical, chemical processing, power generation, water treatment, agricultural machinery, and general engineering.

Why Customers Choose Trojan Special Fasteners

What Makes Us Different

31+ Years of Proven Excellence

Since 1991, we've built an unrivalled reputation for precision fastener manufacturing. Our decades of experience mean we've encountered and solved most fastener challenges before.

*ISO 9001:2015 Quality Assuranc*e

Certified quality management system with full traceability and comprehensive documentation available for every order.

Bespoke Manufacturing Specialists

The unusual jobs others can't or won't do are our speciality. If you can draw it, we can make it.

Birmingham Made

All manufacturing in-house at our Birmingham facility. Supporting UK manufacturing and providing local jobs.

Technical Expertise

Our team includes experienced engineers who can assist with specification, material selection, and design optimisation.

Rapid Response

Same-day quotes, 3-10 day turnaround, expedited service available.

Any Quantity

From single prototypes to thousands. No minimum order quantity.

Competitive Pricing

Fair, transparent pricing. No middlemen markups.

Excellent Communication

Responsive, helpful, honest. We keep you informed throughout.

FAQs

Frequently Asked Questions

What sizes of nuts can you manufacture?

We manufacture nuts from M3 up to M52+ in metric sizes, and from 6BA to 2.1/4" in imperial and unified sizes. We can also produce non-standard and intermediate sizes to customer specifications. If you need something larger, contact us – we'll find a solution.

Do you offer custom thread forms?

Yes, absolutely. In addition to standard metric, unified, and Whitworth threads, we can manufacture nuts with custom pitch threads, left-hand threads, multi-start threads, oversized threads, and mixed thread combinations (e.g., metric one end, imperial the other). Just provide your specification.

What materials do you work with?

We work with a comprehensive range including mild steel, high tensile steel (Grade 8/10/12), stainless steel (303/304/316), brass (CZ121/CW614N), phosphor bronze, NES833, aluminium (6082/2011), copper, and other materials including Nylon. Material certificates are available upon request.

What is your typical lead time?

For standard items in common materials, 3-5 working days. For bespoke items or unusual materials, 7-10 working days. We offer expedited service for genuine urgencies – contact us to discuss your timeline.

Can you manufacture from samples or drawings?

Yes, we regularly work from customer samples or technical drawings. Send us your sample nut or a dimensioned drawing (PDF, DWG, DXF), and we'll provide a quote. We can also work from verbal specifications for simpler items.

Do you offer free-issue machining services?

Yes, we offer comprehensive contract machining services including tapping, polygon turning, slotting, drilling, boring, and thread distortion. You can supply your raw materials or blanks, and we'll machine them to your specification. Visit our Services page for details.

What quality certifications can you provide?

We are ISO 9001:2015 certified. For individual orders, we can provide material certificates (EN 10204 3.1), heat treatment certificates (where applicable), plating/coating certificates, certificates of conformity, and inspection reports. Full traceability is maintained throughout production.

What is your minimum order quantity?

We have no minimum order quantity. We're happy to manufacture single prototypes, small batches for trials, or full production runs into the thousands.

Can you help with material selection?

Yes, our technical team can advise on the most appropriate material for your application based on environmental factors, strength requirements, temperature, chemical exposure, and cost considerations.

Do you export outside the UK?

Yes, we can supply to customers across Europe and can arrange shipping worldwide.

Ready to Discuss Your Fastener Requirements?

At Trojan Special Fasteners Ltd, we are proud of our expertise and experience in the fastener manufacturing industry, and we are committed to delivering the best possible products and services to our customers. If you're in need of custom fasteners, we would be honoured to work with you to create a solution that meets your needs.

Contact us today:

- Phone: +44 (0)121 789 8586

- Address: 18 Fortnum Close, Kitts Green, Birmingham B33 0LG

- Click the icons on the top right of the page