Whitworth Threads

Whitworth Threads: Complete Technical Guide to BSW, BSF & Whitform Thread Standards

Whitworth threads represent the world's first standardised screw thread system, revolutionising engineering when Sir Joseph Whitworth introduced them in 1841. At Trojan Special Fasteners, we manufacture precision Whitworth threaded fasteners from 2BA to 2" in diameter, including BSW (British Standard Whitworth), BSF (British Standard Fine), and specialist Whitform threads in both standard and left-hand configurations.

Understanding Whitworth Thread Geometry

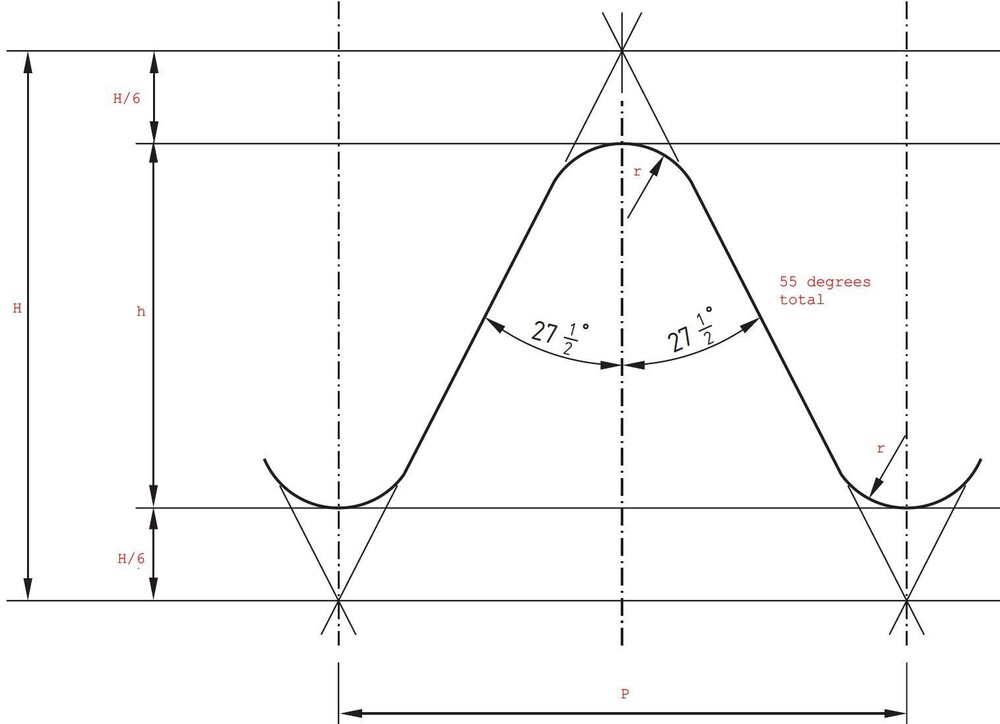

The distinctive Whitworth thread profile features a 55-degree included angle between thread flanks, setting it apart from modern 60-degree metric and unified threads. This geometry, combined with radiused roots and crests, creates exceptional strength and resistance to fatigue failure. The thread depth equals 0.640327 times the pitch, whilst the radius at roots and crests measures 0.137329 times the pitch, providing the characteristic rounded profile that distributes stress effectively.

Key geometric characteristics:

- Thread angle: 55 degrees

- Flank angle: 27.5 degrees (perpendicular to axis)

- Thread depth (h): 0.640327 × pitch (h=0.640327P)

- Root radius: 0.137329 × pitch (r=0.137329P)

- Crest radius: 0.137329 × pitch (r=0.137329P)

- Height of fundamental triangle: 0.960491 × pitch (H=0.960491P)

Historical Development and Legacy

Prior to Whitworth's innovation, British engineering suffered from a chaotic mixture of proprietary thread systems, with each manufacturer using different specifications. This "thread babel" made interchangeability impossible and significantly hindered industrial progress. Whitworth's standardisation transformed manufacturing, enabling mass production and the interchange of components between different manufacturers.

The British government formally adopted Whitworth threads as the national standard in 1881, codified in BS 84. Though largely superseded by metric standards in modern manufacturing, Whitworth threads remain essential for:

- Restoration of vintage machinery and vehicles

- Heritage railway maintenance

- Classic British motorcycles and automobiles

- Marine applications on traditional vessels

- Agricultural machinery repair

- Industrial heritage projects

BSW (British Standard Whitworth) Specifications

BSW threads employ a coarse pitch series optimised for general engineering applications. The coarse pitch provides:

- Superior strength in cast iron and softer materials

- Enhanced resistance to stripping

- Easier assembly and disassembly

- Better performance under vibration

- Reduced risk of cross-threading

Common BSW sizes we manufacture:

1/4" BSW (20 TPI), 5/16" BSW (18 TPI), 3/8" BSW (16 TPI), 7/16" BSW (14 TPI), 1/2" BSW (12 TPI), 9/16" BSW (12 TPI), 5/8" BSW (11 TPI), 3/4" BSW (10 TPI), 7/8" BSW (9 TPI), 1" BSW (8 TPI), 1.1/8" BSW (7 TPI), 1.1/4" BSW (7 TPI), 1.3/8" BSW (6 TPI), 1.1/2" BSW (6 TPI), 1.5/8" BSW (5 TPI), 1.3/4" BSW (5 TPI), 1.7/8" BSW (4.5 TPI), 2" BSW (4.5 TPI)

BSF (British Standard Fine) Specifications

BSF threads utilise finer pitches than BSW whilst maintaining the same 55-degree thread form. Fine pitch advantages include:

- Increased minor diameter providing greater core strength

- Improved adjustment precision for instruments

- Better locking characteristics

- Reduced tendency to loosen under vibration

- Superior performance in thin-walled components

Common BSF sizes we manufacture:

3/16" BSF (32 TPI), 1/4" BSF (26 TPI), 5/16" BSF (22 TPI), 3/8" BSF (20 TPI), 7/16" BSF (18 TPI), 1/2" BSF (16 TPI), 9/16" BSF (16 TPI), 5/8" BSF (14 TPI), 3/4" BSF (12 TPI), 7/8" BSF (11 TPI), 1" BSF (10 TPI), 1.1/8" BSF (9 TPI), 1.1/4" BSF (9 TPI), 1.3/8" BSF (8 TPI), 1.1/2" BSF (8 TPI), 1.5/8" BSF (8 TPI), 1.3/4" BSF (7 TPI), 2" BSF (7 TPI)

Whitform Threads: Non-Standard Whitworth Forms

Whitform threads maintain the standard Whitworth 55-degree thread angle and rounded root/crest profile but employ non-standard pitch combinations not covered by BSW or BSF specifications. Important correction: Whitform threads use 55-degree angles, NOT 60 degrees.

Whitform applications include:

- Specialised machinery requiring unique pitch/diameter combinations

- Replacement parts for obsolete equipment

- Custom engineering solutions

- Model engineering projects

- Instrument and precision apparatus

Examples of Whitform threads:

- 1/4" × 24 TPI (neither BSW nor BSF standard)

- 5/16" × 24 TPI

- 3/8" × 24 TPI

- 1/2" × 14 TPI

- Special pitches for specific machinery manufacturers

Manufacturing Capabilities at Trojan Special Fasteners

We manufacture Whitworth threaded fasteners across an extensive range:

Imperial Whitworth Range:

- 2BA to 2" diameter

- BSW, BSF, and Whitform specifications

- Standard right-hand and left-hand threads

- Special pitches to customer requirements

- Oversize threads for repair applications

Materials Available:

- Mild steel to BS 970

- EN8, 212A42, 080A42, C45, EN16T, EN19T, EN24T

- Stainless steel (A1/303, A2/304, A4/316)

- Brass (CZ121, CZ122)

- Phosphor bronze

- Aluminium alloys

- Special alloys on request

Product Types:

- Hexagon nuts (full, thin, castle, nyloc)

- Square nuts

- Round nuts

- Nylon Insert Nuts

- All Metal Prevailing Torque Locking Nuts

- Castle and Slotted Nuts

- Stay and Crown Stay Nuts

- Pre-war BS190 and BS191 nuts

- Specialist nuts (made to your drawing or sample)

- Custom-designed fasteners

Thread Identification and Measurement

Accurate identification of Whitworth threads requires:

- Measure the outside diameter (imperial measurement)

- Count threads per inch (TPI) over a 1" length

- Check thread angle (must be 55 degrees)

- Verify root and crest radius presence

- Compare against BSW/BSF standards

Designation examples:

- 1/2" BSW = 1/2 inch diameter, 12 TPI, coarse series

- 1/2" BSF = 1/2 inch diameter, 16 TPI, fine series

- 1/2" × 14 TPI Whitform = non-standard pitch

Relevant Standards and Specifications

Current Standards:

- BS 84:2007 - ISO metric screw threads (superseded BSW/BSF)

- BS 84:1956 - Original BSW and BSF specifications (withdrawn but still referenced)

- BS 93:1951 - British Association (BA) screw threads

- BS 811:1950 - Model Engineer (ME) threads

Related Thread Standards Using 55-Degree Angles:

- BSP (British Standard Pipe) - BS EN ISO 228-1

- BSPP (British Standard Pipe Parallel)

- BSPT (British Standard Pipe Taper) - BS 21

- BSCon (British Standard Conduit)

- BSCopper (British Standard Copper)

Obsolete and Withdrawn Standards We Can Supply:

- BS 84:1940 - Wartime simplified BSW/BSF

- BS 84:1956 - Full BSW/BSF specification

- BS 811:1950 - Model Engineer threads

- BS 1580:1949 - Unified threads (transitional)

- CEI (Cycle Engineers Institute) - Pre-BSC cycle threads

- Various military specifications (DEF STAN, NES, NAV)

International Cross-References

Commonwealth Standards:

- AS 1275 (Australian Standard)

- CSA B1.1 (Canadian Standards Association)

- IS 1363 (Indian Standard)

- SABS 1700 (South African Standard)

Historical Military Specifications:

- DEF STAN 05-10 (UK Defence Standard)

- NES 503 (Naval Engineering Standard)

- AGS (Aircraft General Standard)

- DTD (Directorate of Technical Development)

Quality Control and Testing

Our Whitworth threaded products undergo rigorous inspection:

- Thread plug and ring gauge testing to BS 919

- Pitch diameter measurement using thread micrometers

- Root and crest radius verification

- Surface finish inspection

- Material certification to relevant standards

- Dimensional reports available on request

Applications by Industry

Heritage and Restoration:

- Steam engines and traction engines

- Vintage motorcycles (BSA, Norton, Triumph, Royal Enfield)

- Classic cars (pre-1970s British vehicles)

- Heritage railway rolling stock

- Industrial archaeology projects

- Museum restoration work

Marine and Offshore:

- Traditional boat building

- Historic vessel restoration

- Dock and harbour equipment

- Marine heritage projects

Agricultural and Industrial:

- Vintage tractor restoration

- Historic machinery maintenance

- Mill and factory heritage equipment

- Traditional engineering workshops

Technical Support and Custom Solutions

Our technical team provides:

- Thread identification service

- Custom thread design

- Material selection guidance

- Obsolete thread matching

- Technical drawings and CAD models

- Prototype development

Frequently Asked Questions (FAQ)

What is the difference between BSW and BSF threads?

BSW (British Standard Whitworth) uses coarse pitches optimised for general engineering, whilst BSF (British Standard Fine) employs finer pitches for applications requiring greater precision or increased core strength. Both use the same 55-degree thread angle and rounded profile.

Are Whitworth threads still manufactured?

Yes, Trojan Special Fasteners actively manufactures Whitworth threaded fasteners from 2BA to 2" diameter. We maintain extensive tooling for BSW, BSF, and Whitform threads to support restoration projects and legacy equipment maintenance.

What angle are Whitworth threads?

All Whitworth threads, including BSW, BSF, and Whitform, feature a 55-degree included angle between thread flanks. This differs from the 60-degree angle used in metric and unified threads.

Can I use metric fasteners to replace Whitworth?

No, metric and Whitworth threads are incompatible due to different thread angles (60° vs 55°), pitches, and root/crest profiles. Using incorrect threads risks damaging components and creating unsafe assemblies.

What is a Whitform thread?

Whitform threads maintain the standard Whitworth 55-degree angle and rounded profile but use non-standard pitch combinations not specified in BSW or BSF standards. They're commonly found in specialised machinery and instruments, especially in older items.

How do I identify a Whitworth thread?

Measure the diameter in imperial units, count the threads per inch, and verify the 55-degree thread angle. Compare measurements against BSW/BSF standards. Our technical team offers a free identification service for unclear threads.

Are left-hand Whitworth threads available?

Yes, we manufacture left-hand threads in most Whitworth specifications. These are commonly required for turnbuckles, certain automotive applications, and machinery where reverse rotation could cause loosening.

What materials are available for Whitworth fasteners?

We offer mild steel, high tensile steel, EN8, EN16T, stainless steel (303/304/316), brass, phosphor bronze, aluminium alloys, and special materials including duplex stainless steel, naval brass, and silicon bronze.

Do you supply Whitworth fasteners to military specifications?

Yes, we can manufacture to obsolete military specifications including DEF STAN, NES, and various DTD specifications. We maintain records of many withdrawn standards.

What is the largest Whitworth thread you can supply?

Our standard range extends to 2" diameter.

Can you match threads from old machinery?

Yes, our technical team specialises in identifying and matching obsolete threads. Send us a sample or detailed measurements, and we'll determine the specification and manufacturing feasibility.

What's the difference between Whitworth and BSP threads?

BSP (British Standard Pipe) threads derived from Whitworth, sharing the 55-degree angle and rounded profile. However, BSP threads are designated by bore size rather than thread diameter and use specific pitches for sealing.

Do Whitworth threads seal better than metric?

The rounded root and crest design of Whitworth threads provides excellent stress distribution and fatigue resistance. However, sealing capability depends more on gaskets, sealants, or thread type (parallel vs tapered) than thread form.

Are BA threads the same as Whitworth?

No, British Association (BA) threads use a 47.5-degree angle and metric-based dimensions, despite being a British standard. BA threads are typically smaller (0BA = 6mm and below) and used in precision instruments.

Can you supply obsolete thread standards?

Yes, we specialise in obsolete and withdrawn standards. Our library includes specifications from BS 84:1940, various military standards, and manufacturer-specific threads from British engineering companies.

Contact Our Technical Team

For assistance with Whitworth thread identification, custom manufacturing enquiries, or technical specifications, contact our engineering team:

- Technical drawings and samples welcomed

- Free thread identification service

- Custom tooling capabilities

- Rapid prototyping available

- Heritage project specialists

Trojan Special Fasteners Ltd - Your trusted partner for precision Whitworth threaded fasteners since 1976. From 2BA to 2" diameter, standard to special, we manufacture the threads that keep Britain's engineering heritage running.

BSW - British Standard Whitworth Basic Sizes

All sizes are in inches

| SIZE | TPI | PITCH | h | MAJOR DIA | EFFECTIVE DIA | MINOR DIA |

|---|---|---|---|---|---|---|

| 1/8 | 40 | 0.02500 | 0.0160 | 0.1250 | 0.1090 | 0.0930 |

| 3/16 | 24 | 0.04167 | 0.0267 | 0.1875 | 0.1608 | 0.1341 |

| 1/4 | 20 | 0.05000 | 0.0320 | 0.2500 | 0.2180 | 0.1860 |

| 5/16 | 18 | 0.05556 | 0.0356 | 0.3125 | 0.2769 | 0.2413 |

| 3/8 | 16 | 0.06250 | 0.0400 | 0.3750 | 0.3350 | 0.2950 |

| 7/16 | 14 | 0.07143 | 0.0457 | 0.4375 | 0.3918 | 0.3461 |

| 1/2 | 12 | 0.08333 | 0.0534 | 0.5000 | 0.4466 | 0.3932 |

| 9/16 | 12 | 0.08333 | 0.0534 | 0.5625 | 0.5091 | 0.4557 |

| 5/8 | 11 | 0.09091 | 0.0582 | 0.6250 | 0.5668 | 0.5086 |

| 11/16 | 11 | 0.09091 | 0.0582 | 0.6875 | 0.6293 | 0.5711 |

| 3/4 | 10 | 0.10000 | 0.0640 | 0.7500 | 0.6860 | 0.6220 |

| 7/8 | 9 | 0.11111 | 0.0711 | 0.8750 | 0.8039 | 0.7328 |

| 1 | 8 | 0.12500 | 0.0800 | 1.0000 | 0.9200 | 0.8400 |

| 1.1/8 | 7 | 0.14286 | 0.0915 | 1.1250 | 1.0335 | 0.9420 |

| 1.1/4 | 7 | 0.14286 | 0.0915 | 1.2500 | 1.1585 | 1.0670 |

| 1.1/2 | 6 | 0.16667 | 0.1067 | 1.5000 | 1.1393 | 1.2866 |

| 1.3/4 | 5 | 0.20000 | 0.1281 | 1.7500 | 1.6219 | 1.4938 |

| 2 | 4.5 | 0.22222 | 0.1423 | 2.0000 | 1.8577 | 1.7154 |

| 2.1/4 | 4 | 0.25000 | 0.1601 | 2.2500 | 2.0899 | 1.9298 |

| 2.1/2 | 4 | 0.25000 | 0.1601 | 2.5000 | 2.3399 | 2.1798 |

| 2.3/4 | 3.5 | 0.28571 | 0.1830 | 2.7500 | 2.5670 | 2.3840 |

| 3 | 3.5 | 0.28571 | 0.1830 | 3.0000 | 2.8170 | 2.6340 |

| 3.1/4 | 3.25 | 0.30769 | 0.1970 | 3.2500 | 3.0530 | 2.8560 |

| 3.1/2 | 3.25 | 0.30769 | 0.1970 | 3.5000 | 3.3030 | 3.1060 |

| 3.3/4 | 3 | 0.33333 | 0.2134 | 3.7500 | 3.5366 | 3.2332 |

| 4 | 3 | 0.33333 | 0.2134 | 4.0000 | 3.7866 | 3.5732 |

| 4.1/2 | 2.875 | 0.34783 | 0.2227 | 4.5000 | 4.2773 | 4.0546 |

| 5 | 2.75 | 0.36364 | 0.2328 | 5.0000 | 4.7672 | 4.5344 |

| 5.1/2 | 2.625 | 0.38095 | 0.2439 | 5.5000 | 5.2561 | 5.0122 |

| 6 | 2.5 | 0.40000 | 0.2561 | 6.0000 | 5.7439 | 5.4878 |

BSF - British Standard Fine Threads Basic Sizes

All sizes are in inches

| SIZE | TPI | PITCH | h | MAJOR DIA | EFFECTIVE DIA | MINOR DIA |

|---|---|---|---|---|---|---|

| 3/16 | 32 | 0.03125 | 0.0200 | 0.1875 | 0.1675 | 0.1475 |

| 7/32 | 28 | 0.03571 | 0.0229 | 0.2188 | 0.1959 | 0.1730 |

| 1/4 | 26 | 0.03846 | 0.0246 | 0.2500 | 0.2254 | 0.2008 |

| 9/32 | 26 | 0.03846 | 0.0246 | 0.2812 | 0.2566 | 0.2320 |

| 5/16 | 22 | 0.04545 | 0.0291 | 0.3125 | 0.2834 | 0.2543 |

| 3/8 | 20 | 0.05000 | 0.0320 | 0.3750 | 0.3430 | 0.3110 |

| 7/16 | 18 | 0.05556 | 0.0356 | 0.4375 | 0.4019 | 0.3663 |

| 1/2 | 16 | 0.06250 | 0.0400 | 0.5000 | 0.4600 | 0.4200 |

| 9/16 | 16 | 0.06250 | 0.0400 | 0.5625 | 0.5225 | 0.4825 |

| 5/8 | 14 | 0.07143 | 0.0457 | 0.6250 | 0.5793 | 0.5336 |

| 11/16 | 14 | 0.07143 | 0.0457 | 0.6875 | 0.6418 | 0.5961 |

| 3/4 | 12 | 0.08333 | 0.0534 | 0.7500 | 0.6966 | 0.6432 |

| 7/8 | 11 | 0.09091 | 0.0582 | 0.8750 | 0.8168 | 0.7586 |

| 1 | 10 | 0.10000 | 0.0640 | 1.0000 | 0.9360 | 0.8720 |

| 1.1/8 | 9 | 0.11111 | 0.0711 | 1.1250 | 1.0539 | 0.9828 |

| 1.1/4 | 9 | 0.11111 | 0.0711 | 1.2500 | 1.1789 | 1.1078 |

| 1.3/8 | 8 | 0.12500 | 0.0800 | 1.3750 | 1.2950 | 1.2150 |

| 1.1/2 | 8 | 0.12500 | 0.0800 | 1.5000 | 1.4200 | 1.3400 |

| 1.5/8 | 8 | 0.12500 | 0.0800 | 1.6250 | 1.5450 | 1.4650 |

| 1.3/4 | 7 | 0.14286 | 0.0915 | 1.7500 | 1.6585 | 1.5670 |

| 2 | 7 | 0.14286 | 0.0915 | 2.0000 | 1.9085 | 1.8170 |

| 2.1/4 | 6 | 0.16667 | 0.1067 | 2.2500 | 2.1433 | 2.0366 |

| 2.1/2 | 6 | 0.16667 | 0.1067 | 2.5000 | 2.3933 | 2.2866 |

| 2.3/4 | 6 | 0.16667 | 0.1067 | 2.7500 | 2.6433 | 2.5366 |

| 3 | 5 | 0.20000 | 0.1281 | 3.0000 | 2.8719 | 2.7438 |

| 3.1/4 | 5 | 0.20000 | 0.1281 | 3.2500 | 3.1219 | 2.9938 |

| 3.1/2 | 4.5 | 0.22222 | 0.1423 | 3.5000 | 3.3577 | 3.2154 |

| 3.3/4 | 4.5 | 0.22222 | 0.1423 | 3.7500 | 3.6077 | 3.4654 |

| 4 | 4.5 | 0.22222 | 0.1423 | 4.0000 | 3.8577 | 3.7154 |

| 4.1/4 | 4 | 0.25000 | 0.1601 | 4.2500 | 4.0899 | 3.9298 |

Truncated Whitworth Thread

A truncated Whitworth thread is a modified version of the standard Whitworth thread form where the rounded crest is replaced with a flat top, whilst maintaining the characteristic 55-degree thread angle and rounded root profile.

Key Characteristics

Truncated whitworth threads have the following thread geometry:

- Thread angle: 55 degrees (same as standard Whitworth)

- Root profile: Retains the rounded root radius of standard Whitworth

- Crest profile: Flat top instead of rounded (the key difference)

- Truncation amount: Reduces major diameter by 0.147835 × pitch

Historical Context

The truncated Whitworth thread was fully specified in BS 84-1940 (Amendment No. 3, August 1945), developed during World War II as a practical wartime modification. This modification allowed US-made parts to be compatible with British equipment using the same tooling as National/Unified threads, which was important for wartime production efficiency.

Why was the Truncated Whitworth Thread Created?

- Manufacturing simplicity: The flat crest made the thread easier to manufacture than the standard Whitworth form with its rounded crests.

- Tooling compatibility: Could be produced using the same cutting tools as American threads (which had flat crests).

- Wartime efficiency: Enabled faster production during WWII when manufacturing speed was critical.

- Thread compatibility: These threads are compatible with both standard Whitworth threads and the modified form.

Designation

| TWC | Truncated Whitworth Coarse (equivalent to BSW) |

| TWF | Truncated Whitworth Fine (equivalent to BSF) |

| TWPP | Truncated British Standard Pipe Parallel (equivalent to BSPP) |

Practical Implications

Advantages

- Easier to manufacture on standard lathes

- Doesn't require special form tools for the rounded crest

- Still maintains thread strength due to rounded root

- Fully interchangeable with standard Whitworth threads

Modern Usage: When making Whitworth threads on a lathe today, many machinists elect to use the truncated form unless the customer specifically demands the true rounded form, as it's significantly easier to produce whilst maintaining compatibility.

Technical Note for Manufacturing:

At Trojan Special Fasteners, we can produce both standard Whitworth threads with fully radiused crests and truncated Whitworth threads depending on your application requirements. The truncated form is particularly useful for:

- Restoration projects where original tooling limitations existed

- Cost-effective production where full form isn't critical

- Applications where assembly with existing truncated threads is required

The truncated form maintains full compatibility with standard Whitworth threads, so a truncated Whitworth bolt will still properly engage with a standard Whitworth nut and vice versa.