Flange Nuts

Flange Nuts and Collar Nuts: Precision Manufactured Fasteners

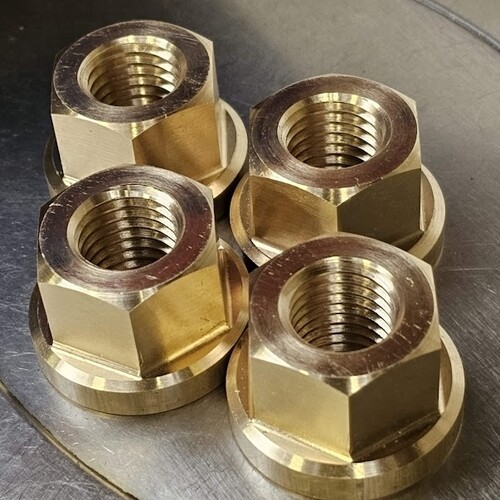

Trojan Special Fasteners Ltd manufactures high-precision flange nuts and collar nuts using advanced bar turning techniques. As a specialist UK fastener manufacturer, we produce standard and bespoke hexagon flange nuts from M3 to M52 in metric sizes(Coarse, Fine, Extra Fine), 2BA to 2" in Imperial (BSW/BSF/Whitform), and #8 to 2.1/4" in Unified (UNF, UNC, UNS, UNEF) thread forms and in left hand and oversize. Our flange and collar nuts deliver superior load distribution, reduced assembly time, and enhanced joint integrity for demanding industrial applications.

What Are Flange Nuts?

Flange nuts are specialised hexagonal fasteners featuring an integral circular flange at the base of the nut body. This built-in flange functions as a fixed washer, providing a significantly larger bearing surface area compared to standard hexagon nuts. The flange distributes clamping forces evenly across the mating surface, reducing localised stress concentrations and minimising the risk of surface damage to softer materials or coated substrates.

The flange eliminates the need for separate washers in many applications, streamlining assembly processes, reducing component counts, and lowering overall production costs. Flange nuts are manufactured through various methods including cold forming, hot forging, and precision bar turning—the latter being Trojan Special Fasteners' preferred manufacturing technique for achieving tight tolerances and superior surface finishes.

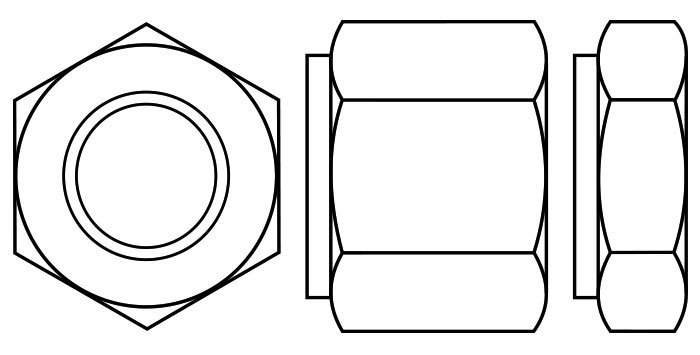

What Are Collar Nuts?

Collar nuts, also known as reduced shank nuts or barrel nuts, feature a cylindrical collar section where the diameter equals or is less than the across-flats dimension of the hexagon. This collar provides similar benefits to flange nuts but with a more compact profile, making them ideal for applications with limited radial clearance or where a lower-profile fastener is required.

The collar provides an extended bearing surface whilst maintaining a smaller footprint than traditional flange nuts. Like flange nuts, collar nuts eliminate the need for additional washers, reducing assembly complexity and potential points of failure in bolted joints.

Why Choose Flange Nuts Over Standard Hexagon Nuts?

Enhanced Load Distribution

The integral flange distributes clamping pressure across a substantially larger surface area—typically 150-200% greater than standard hexagon nuts of equivalent thread size. This increased bearing area reduces contact pressure (measured in N/mm²), preventing surface indentation, deformation of softer materials, and damage to protective coatings such as paint, powder coating, or anodising.

Reduced Installation Time and Cost

By incorporating washer functionality directly into the fastener, flange nuts eliminate the time required to position and align separate washers during assembly. In high-volume manufacturing environments, this translates to significant labour cost savings and improved production throughput. Automated assembly systems benefit particularly from the single-component design, reducing feeder complexity and eliminating washer orientation issues.

Improved Joint Stability

The larger bearing surface area provided by the flange increases friction between the nut and substrate, enhancing resistance to rotational loosening under dynamic loading conditions. Whilst not a substitute for dedicated locking mechanisms in high-vibration environments, the increased surface contact contributes to improved joint stability compared to standard nuts with separate washers.

Better Performance on Uneven Surfaces

When fastening components with slightly irregular, textured, or non-planar surfaces, the flange distributes clamping forces more uniformly, bridging minor surface imperfections. This reduces the likelihood of joint preload variation and prevents localised stress points that could lead to premature fatigue failure.

Prevention of Substrate Damage

Soft materials such as aluminium, plastics, composites, and coated metals are particularly vulnerable to surface damage from concentrated fastener loads. The flange's increased bearing area prevents the nut from biting into or deforming the substrate material, maintaining surface integrity and appearance whilst preserving structural performance.

Resistance to Loosening

Whilst flange nuts should not be considered locking fasteners without additional features, the increased contact area and friction coefficient inherently provide better resistance to vibration-induced loosening compared to standard nuts. For enhanced security, flange nuts can incorporate prevailing torque features such as nylon inserts, deformed threads, or serrated flanges.

Types of Flange and Collar Nuts Manufactured by Trojan Special Fasteners

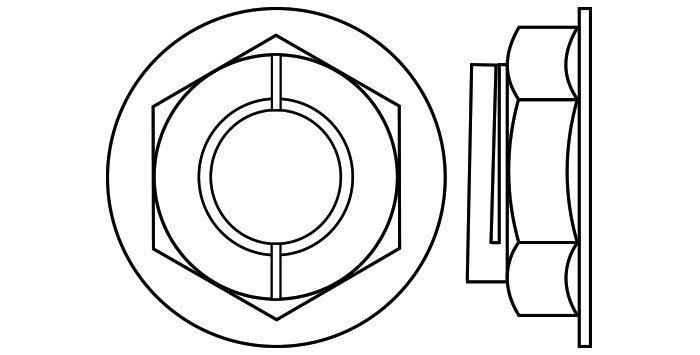

1. Plain Flange Nuts

Standard hexagon flange nuts with smooth, unserrated bearing surfaces. Suitable for general-purpose applications where additional locking features are not required. Available in all standard metric, Imperial, and Unified thread forms.

Key Applications: General machinery assembly, automotive components, furniture manufacturing, electrical enclosures, HVAC equipment.

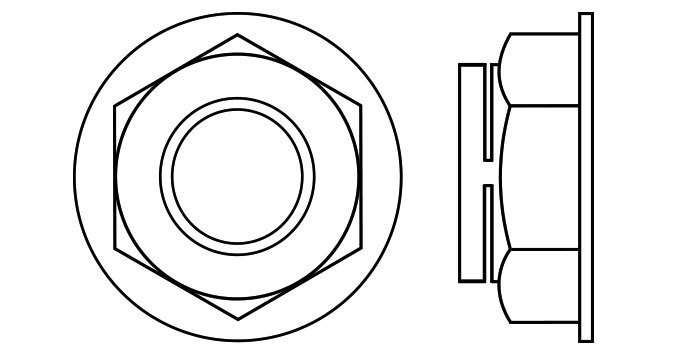

2. Prevailing Torque Locking Flange Nuts

Nylon Insert Flange Nuts

Incorporate a nylon polymer ring in the upper portion of the nut that deforms against the bolt threads, creating friction-based resistance to rotation. Provides reusable locking performance with predictable installation torque. Suitable for temperatures up to 120°C (nylon degradation temperature).

All-Metal Locking Flange Nuts

Feature deformed threads, crimped sections, or axial slots that create interference with the bolt threads. Suitable for higher temperature applications (up to material melting point) where nylon inserts are inappropriate. Available with top-deformation or side-deformation configurations.

Serrated Flange Nuts

Feature radial serrations or teeth on the flange bearing surface that bite into the substrate material, creating additional friction and resistance to rotation. Particularly effective on softer materials and in applications with moderate vibration. Note: Serrations may mark or damage decorative surfaces. At present, Trojan Special Fasteners Ltd does not produce serrations.

Key Applications: Electronics assembly, instrumentation, aerospace panels, automotive trim, appliance manufacturing.

Whilst Trojan Special Fasteners Ltd does not manufacture patented and trademarked items, the following are examples of axially slotted and deformed flange nuts which we have made to our customer’s drawings:

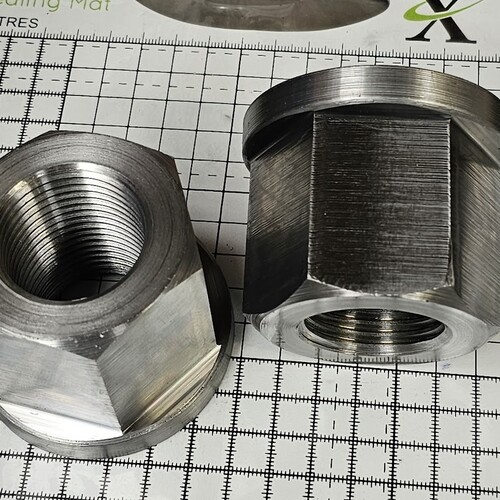

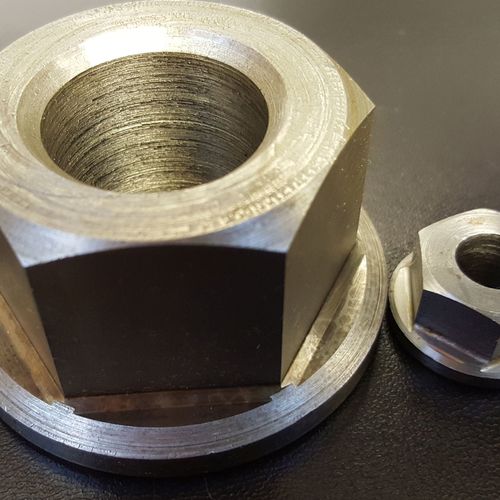

3. Collar Nuts (Reduced Shank Nuts)

Feature a cylindrical collar section with diameter equal to or less than the nut's across-flats dimension. Provide extended bearing length in confined spaces. Ideal for applications requiring precise alignment or captive nut installations. Available in both plain and locking configurations.

Trojan Special Fasteners will manufacture, from bar turning, high precision flange and collar nuts. Flange nuts typically have a large round flange at one end of the nut which acts as a fixed washer. This in effect distributes the pressure of the nut across the part being secured in an even manner which ultimately reduces the chance of damage to the part and lessens any effects of loosening because it’s fastened on an uneven surface.

Trojan special fasteners can also manufacture collar nuts, which have a collar diameter which is equal to or less than the across flat of the nut. Like flange nuts they reduce the need for an additional washer, which helps keep assembly time and costs low.

It is possibly to combine prevailing torque features like the addition of a nylon insert ring, axial slots or thread deformation from the tops or sides into a nut.

Trojan Special Fasteners can axially slot and deform nuts from the top or the sides to provide a prevailing torque feature on your nuts – as no open standard for these exists we would ask that you provide your dimensions or a drawing and we can manufacture to that. Additionally, we can torque test your nuts for you, just provide us with the female threaded part and we’ll take care of the rest!

In addition to standard preferred sizes, we also manufacture non preferred and non standard or special thread and nut forms and sizes.

We can manufacture to the following specifications:

We can manufacture collar and flange nuts to the following specifications:

| Standard | Description |

|---|---|

| ASME/ANSI B18.16.3M | All metal prevailing torque hexagon flange nuts |

| ASME/ANSI B18.16.4 | Large hexagon flange locknuts |

| ASME/ANSI B18.16.4 | Regular hexagon flange locknuts Table 2 |

| ASME/ANSI B18.2.2 | Hex flange nuts Table 12 |

| ASME/ANSI B18.2.2 | Hex flat jam nuts |

| ASME/ANSI B18.2.2 | Hex flat nuts and hex flat jam nuts Table 3 |

| ASME/ANSI B18.2.2 | Large hex flange nuts |

| ASME/ANSI B18.2.2 | Metric hex flange nuts |

| ASME/ANSI B18.2.4.4M | Metric hex flange nuts |

| ASME/ANSI B18.2.6 | Heavy hex flat nuts Table 10 |

| ASME/ANSI B18.2.6 | flat nuts and heavy hex flat jam nuts Table 9 |

| DIN 6331 | Hexagon collar nuts |

| DIN 6923 | Hexagon flange nuts |

| DIN 6926 | Prevailing torque hexagon nylon insert flange nuts |

| DIN 6927 | All metal prevailing torque hexagon flange nuts |

| EN 1661 | Hexagon flange nuts |

| EN 14218 | Hexagon flange nuts with large width across flats |

| Standard | Description |

|---|---|

| IFI 145 | Hexagon flange nuts |

| IFI 145 | Large Hexagon flange nuts |

| ISO 10663 | Hexagon flange nuts |

| ISO 12125 | Prevailing torque hexagon nylon insert flange nuts |

| ISO 12126 | All metal prevailing torque hexagon flange nuts |

| ISO 4161 | Hexagon flange nuts |

| ISO 7043 | Prevailing torque hexagon nylon insert flange nuts |

| NF E25-406 | Hexagon flange nuts |

| NF E25-413 | Prevailing torque hexagon nylon insert flange nuts |

| NF E25-414 | All metal prevailing torque hexagon flange nuts |

| NF E25-420 | All metal prevailing torque hexagon flange nuts, style 2 |

| NF E25-421 | All metal prevailing torque hexagon flange nuts, style 1 |

| NF E25-422 | All metal prevailing torque hexagon flange nuts, style 2 |

| NF E25-506 | Prevailing torque hexagon nylon insert flange nuts |

| NF E25-507 | All metal prevailing torque hexagon flange nuts |

Custom Specifications

For applications requiring non-standard dimensions, special thread forms, or unique performance characteristics, Trojan Special Fasteners manufactures flange and collar nuts to customer drawings and proprietary specifications. Our engineering team works collaboratively with clients to develop optimised fastener solutions.

Flange & Collar Nut Standards

This table shows current and withdrawn standards for flange and collar nuts in various forms. It is not an exhaustive list. Trojan Special Fasteners Limited can manufacture many of these types.

| STANDARD | YEAR | DESCRIPTION | SIZE RANGE | STATUS |

|---|---|---|---|---|

| AECMA EN 2549 | 2001 | Aerospace: Hex nuts, self-locking, with flange | M3 – M12 | Current |

| AFNOR NF E25-400 | 1980 | French general purpose hex nuts with integrated flange | M5 – M20 | Withdrawn |

| ANSI/ASME B18.16.3M | 2004 | Prevailing Torque Metric Hex Flange Nuts | M6 – M30 | Current |

| ANSI/ASME B18.16.4 | 2008 | Serrated Flange Locknuts (Inch) | #6 – 3/4" | Current |

| ANSI/ASME B18.2.2 | 2022 | Square, Hex, and Flange Nuts (Inch) | 1/4" – 1-1/2" | Current |

| ANSI/ASME B18.2.4.4M | 1982 | Metric Hex Flange Nuts | M5 – M20 | Current |

| AS/NZS 1112.3 | 2015 | Metric Hexagon Nuts with Flange (Australia/NZ) | M5 – M64 | Current |

| BS 190 | 1924 | British Standard Whitworth (BSW) High Nuts and Collar Nuts | 1/8" – 3" | Withdrawn |

| BS 4504 | 1989 | Flange Nut specs for Circular Flanges (UK) | M10 – M30 | Withdrawn |

| BS EN 1661 | 1997 | British/EU standard for Flange Nuts | M5 – M20 | Current |

| BS EN 1664 | 1998 | Prevailing torque all-metal flange nuts (UK/EU) | M5 – M20 | Withdrawn |

| BS EN ISO 10663 | 2013 | Hexagon nuts with flange, Style 2 (Fine pitch) | M8 – M20 | Current |

| BS EN ISO 12125 | 2013 | Prevailing torque flange nuts (Nylon - Fine) | M8 – M20 | Current |

| BS EN ISO 12126 | 2013 | Prevailing torque flange nuts (All-metal - Fine) | M8 – M20 | Current |

| BS EN ISO 4161 | 2013 | Hexagon nuts with flange, Style 2 (Coarse) | M5 – M20 | Current |

| BS EN ISO 7043 | 2013 | Prevailing torque flange nuts (Nylon insert) | M5 – M20 | Current |

| BS EN ISO 7044 | 2013 | Prevailing torque flange nuts (All-metal) | M5 – M20 | Current |

| CSN 021443 | 1984 | Czech national standard: Hexagon nuts with flange | M5 – M20 | Withdrawn |

| DIN 2510-5 | 1971 | Bolted connections with reduced shank: Collar nuts | M12 – M110 | Current |

| DIN 6330 | 2003 | Hexagon nuts 1.5d high (Standard Height Collar) | M6 – M48 | Current |

| DIN 6331 | 2003 | Hexagon Nuts with Collar (1.5d Height) | M6 – M48 | Current |

| DIN 6923 | 1983 | Hexagon Flange Nuts (Standard/Serrated) | M5 – M20 | Withdrawn |

| DIN 6926 | 1983 | Nylon insert flange nuts | M5 – M20 | Withdrawn |

| DIN 6927 | 1983 | All-metal prevailing torque hexagon flange nuts | M5 – M20 | Withdrawn |

| DIN 7967 | 1970 | Self-locking counter nuts (Check nuts with collar) | M6 – M64 | Current |

| EN 14218 | 2003 | Hexagon Flange Nuts (Fine pitch, large AF) | M8 – M20 | Current |

| EN 1661 | 1997 | Hexagon Flange Nuts (Standard) | M5 – M20 | Current |

| EN 1663 | 1997 | Prevailing torque hex flange nuts (Nylon insert) | M5 – M20 | Current |

| EN 1664 | 1997 | Prevailing torque hex flange nuts (All-metal) | M5 – M20 | Current |

| GB 6177-1986 | 1986 | Hexagon nuts with flange (Product Grade A) | M5 – M20 | Withdrawn |

| GB 6183-1986 | 1986 | Prevailing torque flange nuts (Non-metallic insert) | M5 – M20 | Withdrawn |

| GB/T 13681-1992 | 1992 | Hexagon weld nuts (General) | M4 – M16 | Withdrawn |

| GB/T 13681.2 | 2017 | Hexagon Weld Nuts with Flange | M5 – M16 | Current |

| GB/T 6177.1 | 2016 | Hexagon Flange Nuts, Style 2 (China) | M5 – M30 | Current |

| GB/T 6177.2 | 2016 | Hexagon Flange Nuts, Style 2 (Fine pitch) | M8 – M30 | Current |

| GB/T 6183.1 | 2000 | Prevailing Torque Hex Flange Nuts (Nylon insert) | M5 – M20 | Current |

| GB/T 6183.2 | 2000 | Prevailing Torque Hex Flange Nuts (All-metal) | M5 – M20 | Current |

| GB/T 6187.1-2000 | 2000 | Prevailing torque all-metal flange nuts (Style 2) | M5 – M20 | Withdrawn |

| GB/T 6187-1986 | 1986 | Prevailing torque all-metal hex nuts with flange | M5 – M20 | Withdrawn |

| GOST 8918-70 | 1970 | Hexagon Nuts with Collar (Russia/CIS) | M6 – M48 | Current |

| IFI 145 | 2002 | Hexagon Flange Nuts (Inch: Unified) | 1/4" – 3/4" | Current |

| IS 15581 | 2005 | Hexagon Nuts with Flange (India) | M5 – M20 | Current |

| ISO 10663 | 2012 | Hexagon Nuts with Flange, Style 2 (Fine pitch) | M8 – M20 | Current |

| ISO 12125 | 2012 | Prevailing torque flange nuts (Nylon insert - Fine) | M8 – M20 | Current |

| ISO 12126 | 2012 | Prevailing torque flange nuts (All-metal - Fine) | M8 – M20 | Current |

| ISO 1662 | 1980 | Pre-ISO 4161 Flange Nut standard | M5 – M20 | Withdrawn |

| ISO 4161 | 2012 | Hexagon Nuts with Flange, Style 2 (Coarse) | M5 – M20 | Current |

| ISO 6162-1 | 2012 | Hydraulic Flange Connector Bolt/Nut Specs | DN 13 – 127 | Current |

| ISO 7043 | 2012 | Prevailing torque hex flange nuts (Nylon insert) | M5 – M20 | Current |

| ISO 7044 | 2012 | Prevailing torque hex flange nuts (All-metal) | M5 – M20 | Current |

| JASO F 126 | 1997 | Japanese Automotive Standard - Flange nuts | M5 – M16 | Current |

| JIS B 1190 | 2014 | Hexagon nuts with flange (General purpose) | M3 – M30 | Current |

| KS B 1043 | 2022 | Hexagon head nuts with flange (Korea) | M5 – M30 | Current |

| MS 51943 | 1970 | Military Standard (US): Nut, Hexagon, Flange (Unified) | 1/4" - 5/8" | Current |

| NAS 1423 | 1992 | National Aerospace Standard: Flange nuts (Unified) | Various | Current |

| NF E25-406 | 1984 | Hexagon flange nuts (France/AFNOR) | M5 – M20 | Withdrawn |

| NF E25-413 | 1984 | Prevailing torque hex flange nuts (Nylon insert) | M5 – M20 | Withdrawn |

| NF E25-414 | 1984 | Prevailing torque hex flange nuts (All-metal) | M5 – M20 | Withdrawn |

| NF E25-422 | 2014 | All-metal prevailing torque flange nuts, Style 2 | M5 – M20 | Current |

| NFE 25411 | 1984 | Hexagon nuts with flange (Old French Standard) | M5 – M20 | Withdrawn |

| ÖNORM M 5275 | 1983 | Austrian standard: Hexagon nuts with collar | M6 – M36 | Current |

| PN-85/M-82110 | 1985 | Hexagon nuts with flange (Old Polish standard) | M5 – M20 | Withdrawn |

| PN-EN 1661 | 2002 | Hexagon flange nuts (Poland/EN-adopted) | M5 – M20 | Current |

| PN-EN 1664 | 2002 | Prevailing torque all-metal flange nuts (Poland) | M5 – M20 | Current |

| SAE J1167 | 2017 | High Strength Flange Nuts (USA Automotive: Unified) | 1/4" - 3/4" | Current |

| SAE J121 | 1997 | Decarburization Limits for Flange Nuts | N/A | Current |

| SN 212745 | 1984 | Swiss standard: Hexagon nuts with collar | M6 – M48 | Current |

| SNV 242332 | 1972 | Swiss (historical): Flanged nuts for jigs | M6 – M36 | Withdrawn |

| STAS 11484-80 | 1980 | Romanian standard: Hexagon nuts with flange | M5 – M20 | Withdrawn |

| UNE-EN 1661 | 1998 | Spanish National Standard for Flange Nuts | M5 – M20 | Current |

| UNI 5593 | 1965 | Hexagon slotted castle nuts with collar (Normal) | M4 – M64 | Current |

| UNI 5594 | 1965 | Hexagon nuts with collar (Equivalent to DIN 6331) | M6 – M52 | Current |

| UNI 5714 | 1966 | Hexagon thin slotted/castle nuts with collar (Low) | M10 – M36 | Current |

| UNI 7044 | 1972 | Self-locking nut with collar (Prevailing torque) | M5 – M20 | Current |

| UNI 74361 | 1975 | Automotive Collar Nuts (Forms A and B) | M12 – M22 | Current |

| VSM 13240 | 1941 | Swiss Pre-war: Hexagon collar nuts | M6 – M36 | Withdrawn |

Manufacturing Capabilities and Size Ranges

Trojan Special Fasteners manufactures flange and collar nuts using precision bar turning techniques, ensuring consistently high quality, excellent dimensional accuracy, and superior surface finishes.

Available Size Ranges:

Metric Threads: M3, M4, M5, M6, M8, M10, M12, M14, M16, M18, M20, M22, M24, M27, M30, M33, M36, M39, M42, M45, M48, M52

Imperial BSW/BSF: 2BA, 1BA, 0BA, 2-56, 4-40, 6-32, 8-32, 10-24, 10-32, 1/4", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 3/4", 7/8", 1", 1.1/8", 1.1/4", 1.3/8", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2"

Unified UNC/UNF: #8, #10, 1/4", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 3/4", 7/8", 1", 1.1/8", 1.1/4", 1.3/8", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2", 2.1/4"

Non-Standard and Special Sizes

In addition to preferred standard sizes, Trojan Special Fasteners manufactures non-preferred sizes, special thread forms, left-hand threads, and completely bespoke nut configurations to customer drawings and specifications.

Material Options for Flange and Collar Nuts

Trojan Special Fasteners manufactures flange and collar nuts from a comprehensive range of engineering materials selected for specific application requirements:

Carbon Steel (Low and Medium Carbon)

Most economical option for general industrial applications. Available in grades A, P, R, T, 1, 5, 6, 8, 10 and 12 for varying strength requirements. Typically supplied with protective surface treatments.

Stainless Steel

- 303 Stainless Steel: Free-machining grade with excellent machinability due to sulphur content. Good corrosion resistance for most environments. Non-magnetic. Ideal for precision turned components where superior surface finish is required.

- 304/A2 Stainless Steel: Excellent corrosion resistance for most environments. Non-magnetic. Suitable for food processing, marine (mild), chemical processing, and architectural applications.

- 316/A4 Stainless Steel: Superior corrosion resistance, particularly against chlorides and marine environments. Non-magnetic. Ideal for coastal installations, chemical plants, pharmaceutical equipment.

- 410/431 Martensitic Stainless: Heat-treatable for higher strength. Magnetic. Moderate corrosion resistance. Used in valve components, pump hardware.

Aluminium Alloys

Lightweight option with excellent corrosion resistance. Typical grades include 6061-T6 and 7075-T6. Used extensively in aerospace, automotive, and electronics applications where weight reduction is critical.

Brass

Good machinability and corrosion resistance. Naturally antimicrobial. Decorative appearance. Used in plumbing fittings, electrical components, musical instruments, architectural hardware.

Bronze

Excellent wear resistance and corrosion resistance, particularly in marine environments. Used in marine hardware, bearings, bushings, and pump components. We include material such as Aluminium Bronze, Phosphor Bronze and Nickel Bronze.

Copper

Excellent electrical and thermal conductivity. High corrosion resistance. Used in electrical earthing applications, busbars, heat exchangers.

Surface Treatments and Coatings

To enhance corrosion resistance, appearance, and functional properties, flange nuts can be supplied with various surface treatments:

- Zinc Plating (Clear or Yellow): Economical corrosion protection for indoor and mild outdoor applications. Typically provides 96-720 hours salt spray resistance depending on thickness.

- Zinc-Nickel Plating: Superior corrosion resistance compared to zinc. Automotive industry standard for under-bonnet applications. 720+ hours salt spray resistance.

- Hot-Dip Galvanising: Thick zinc coating for maximum corrosion protection. Ideal for outdoor structural applications, infrastructure, agricultural equipment.

- Zinc Flake Coating (e.g., Dacromet, Geomet): Excellent corrosion protection with no hydrogen embrittlement risk. Automotive and fastener industry standard. 1000+ hours salt spray resistance.

- Black Oxide: Provides mild corrosion resistance and aesthetic black finish. Commonly used with oil coating for improved protection.

- Phosphate Coating: Improves paint adhesion and provides corrosion resistance under paint systems. Pre-treatment for powder coating.

- Electroless Nickel Plating: Uniform coating thickness, excellent corrosion resistance, good wear resistance.

- Passivation (Stainless Steel): Chemical treatment that removes free iron and enhances the naturally corrosion-resistant chromium oxide layer.

- Anodising (Aluminium): Creates hard, durable, corrosion-resistant surface. Available in natural (clear) or various colours.

Key Industries and Applications

Automotive and Transportation

Flange nuts are extensively used throughout automotive manufacturing for chassis assembly, suspension components, brake systems, steering mechanisms, body panels, and interior trim. The integrated washer function reduces assembly time on production lines whilst the increased bearing surface prevents damage to painted and coated surfaces. Prevailing torque locking variants ensure security in high-vibration environments.

Aerospace and Aviation

Lightweight aluminium and titanium flange nuts are critical components in aircraft structures, engine mounts, control surfaces, and interior assemblies. The weight saving from eliminating separate washers contributes to overall aircraft efficiency whilst maintaining structural integrity under extreme conditions.

Heavy Machinery and Construction Equipment

Large-diameter flange nuts secure critical components in excavators, cranes, bulldozers, and agricultural machinery. The robust flange design distributes high clamping loads across structural members, preventing deformation and ensuring reliable operation in harsh working environments.

Renewable Energy

Wind turbine assemblies, solar panel mounting systems, and hydroelectric installations rely on corrosion-resistant stainless steel and hot-dip galvanised flange nuts. The flange design provides superior load distribution on composite materials commonly used in modern renewable energy structures.

Marine and Offshore

Bronze and 316 stainless steel flange nuts deliver exceptional corrosion resistance in saltwater environments. Used extensively in ship building, offshore platforms, subsea equipment, and marine propulsion systems where reliability is paramount.

Electronics and Electrical Equipment

Small-diameter collar nuts (M3-M6) provide compact fastening solutions for circuit boards, enclosures, switches, and connectors. Brass and aluminium variants offer electrical conductivity where earthing or grounding is required.

Rail Transport

Flange nuts secure track components, signalling equipment, rolling stock assemblies, and station infrastructure. Hot-dip galvanised finishes provide long-term corrosion protection for outdoor installations whilst meeting stringent railway industry safety standards.

Medical and Pharmaceutical Equipment

316 stainless steel flange nuts manufactured to pharmaceutical-grade standards ensure cleanliness, corrosion resistance, and biocompatibility in medical devices, diagnostic equipment, and pharmaceutical processing machinery.

Food and Beverage Processing

304 and 316 stainless steel flange nuts meet FDA and EU food contact requirements. Smooth surfaces facilitate cleaning and prevent bacterial harbourage in filling equipment, processing lines, and packaging machinery.

How to Select the Right Flange Nut for Your Application

Selecting the optimal flange nut requires consideration of multiple factors:

1. Thread Size and Type

Determine the bolt or stud thread size (diameter and pitch) that the nut must engage. Specify metric (M8 x 1.25), Imperial BSW (1/2" - 12 TPI), or Unified UNC (1/2" - 13 TPI) thread form. Ensure compatibility between male and female threads.

2. Material Selection

Consider the operating environment:

- Indoor, dry environments: Carbon steel with zinc plating

- Outdoor, mild corrosion: 304 stainless steel or hot-dip galvanised carbon steel

- Marine or chemical exposure: 316 stainless steel, bronze, or Monel

- High temperature (>400°C): Stainless steel 310, Inconel, or other heat-resistant alloys

- Weight-critical applications: Aluminium alloys or titanium

- Electrical conductivity required: Brass, copper, or aluminium

3. Strength Requirements

Match nut grade to bolt grade to ensure balanced joint strength:

- Grade 8.8 carbon steel nuts: For Grade 8.8 bolts (800 N/mm² tensile strength)

- Grade 10.9 carbon steel nuts: For Grade 10.9 and 12.9 bolts

- A2-70 stainless steel nuts: For A2-70 stainless bolts

- A4-80 stainless steel nuts: For A4-80 stainless bolts (higher strength)

Under-specifying nut strength relative to bolt strength may result in nut thread stripping before bolt achieves proper preload.

4. Locking Requirements

Assess vibration levels and consequence of loosening:

- Low vibration, low criticality: Plain flange nut

- Moderate vibration: Serrated flange nut or nylon insert variant

- High vibration or critical applications: All-metal locking flange nut, or plain flange nut with additional locking mechanism (anaerobic threadlocker, lock wire, split pins)

- High temperature + vibration: All-metal locking variants only (nylon inserts degrade above 120°C)

5. Flange Diameter and Thickness

Consider clearance constraints and load distribution requirements. Standard flange diameters typically range from 1.5× to 2× the across-flats dimension. Larger flanges provide greater load distribution but require more radial clearance.

6. Surface Compatibility

Consider substrate material:

- Soft materials (plastics, aluminium, wood): Larger flange for maximum load distribution

- Decorative surfaces: Avoid serrated flanges; select smooth bearing surface

- Uneven surfaces: Flange helps bridge irregularities better than standard nuts

7. Assembly Method

- Manual installation: Standard flange nuts

- Powered tools (impact wrenches): Ensure adequate flange thickness to resist deformation

- Automated assembly: Consistent flange geometry aids robotic handling

8. Certification and Traceability

For aerospace, medical, nuclear, or other critical applications, specify material certification requirements (mill test certificates, 3.1 certification per EN 10204) and any required traceability markings.

Technical Specifications and Dimensions

Key Dimensional Parameters:

- Thread Size (d): Major diameter of internal thread

- Pitch (P): Distance between adjacent thread crests

- Width Across Flats (s): Hexagon dimension for wrench engagement

- Width Across Corners (e): Diagonal dimension of hexagon

- Overall Height (m): Total thickness from bearing surface to top face

- Flange Diameter (dc): External diameter of bearing flange

- Flange Thickness (c): Thickness of flange washer section

- Thread Length (m_min): Minimum engaged thread length

- Collar Diameter (dc_collar): For collar nuts, diameter of reduced shank section

- Collar Length (l_collar): Length of collar section

Installation Guidelines and Best Practices

Torque Specifications

Proper tightening torque ensures adequate preload without exceeding material yield strength. Torque values depend on thread size, material grade, lubrication condition, and surface finish. Consult relevant torque charts for specific applications.

General Torque Guidance (Carbon Steel, Grade 8.8, Dry Assembly):

- M6: 8-10 N⋅m

- M8: 20-25 N⋅m

- M10: 40-50 N⋅m

- M12: 70-85 N⋅m

- M16: 160-200 N⋅m

- M20: 330-400 N⋅m

Lubricated threads require approximately 20-30% reduced torque to achieve equivalent preload due to reduced friction.

Thread Engagement

Ensure minimum thread engagement length equals 1× thread diameter for steel-into-steel joints, 1.5× diameter for steel-into-aluminium, and 2× diameter for steel-into-plastic. Insufficient engagement may result in thread stripping.

Flange Orientation

Always install flange nuts with the flange bearing against the substrate. The flange should contact the maximum available bearing surface area. Do not install flange nuts "upside down" (flange facing away from substrate).

Surface Preparation

Clean bearing surfaces of paint drips, burrs, metal chips, and contamination before installation. Ensure surfaces are reasonably flat and perpendicular to the bolt axis for optimal load distribution.

Locking Nut Installation

- Nylon insert nuts: May require slightly higher initial installation torque. Check manufacturer's specifications.

- All-metal locking nuts: Installation torque will be higher than plain nuts due to thread interference. Do not reuse if prevailing torque is lost.

- Serrated flange nuts: May require higher installation torque as serrations bite into substrate. Will leave witness marks on bearing surface.

Reusability

Plain flange nuts can typically be reused multiple times if threads remain undamaged. Prevailing torque locking nuts should be inspected after removal—replace if prevailing torque feature is worn or damaged. Nylon insert nuts should generally be replaced after removal as the nylon may be degraded.

Comparison: Flange Nuts vs. Standard Nuts with Washers

| FEATURE | Flange Nut | Standard Nut + Washer |

|---|---|---|

| Component Count | Single Component | Two Components |

| Assembly Time | Faster - one component to position | Slower - washer must be oriented |

| Load Distribution | Excellent - Integral Flange | Good - depends on washer size |

| Height Profile | Moderate | Lower overall height possible |

| Resistance to Loosening | Better - increased bearing friction | Standard |

| Cost per Component | Higher unit cost | Lower total cost (two items) |

| Automated Assembly | Simpler - one feeder | More complex - two feeders |

| Soft Material Protection | Excellent | Good |

| Vibration Resistance | Better (larger contact area) | Requires locking mechanism |

| Lost Component Risk | None - washer integral | Washer may be lost/omitted |

| Standardisation | Multiple international standards | Universal washer compatibility |

| Radial Clearance Required | More - larger flange diameter | Less - compact Profile |

| FEATURE | FLANGE NUT | COLLAR NUT |

|---|---|---|

| Bearing Surface Profile | Wide circular flange | Cylindrical collar |

| Radial Clearance | Requires more space | Compact - minimal clearance |

| Load Distribution Area | Maximum | Moderate |

| Typical Applications | General Assembly | Confined spaces, panels |

| Alignment Guidance | None | Collar provides centering |

| Height Profile | Standard | Can be taller (extended collar) |

| Substrate Damage Protection | Excellent | Good |

| Aesthetic Appearance | Prominent flange visible | Lower profile |

| Captive Installation | Not typically captive | Can function as a captive nut |

Frequently Asked Questions (FAQs)

Q: Can flange nuts be used in high-vibration environments?

A: Plain flange nuts provide improved vibration resistance compared to standard nuts due to increased bearing area and friction, but they are not classified as locking fasteners. For high-vibration applications, specify prevailing torque locking variants (nylon insert or all-metal locking types) or use supplementary locking methods such as anaerobic threadlockers, lock wire, or castellated nuts with split pins. Serrated flange nuts also provide enhanced vibration resistance by biting into the substrate surface.

Q: What is the difference between a serrated flange nut and a plain flange nut?

A: Serrated flange nuts feature radial teeth or serrations on the underside of the flange bearing surface. These serrations bite into the mating surface during tightening, creating additional friction and mechanical interlock that resists rotational loosening. Plain flange nuts have smooth bearing surfaces. Serrated variants are preferred for vibration-prone applications but may mark or damage decorative surfaces, powder coating, or soft materials.

Q: Can I reuse flange nuts?

A: Plain carbon steel and stainless steel flange nuts can generally be reused multiple times provided the threads are not damaged, cross-threaded, or deformed. Inspect threads visually and check for smooth engagement before reuse. Prevailing torque locking flange nuts (nylon insert or deformed thread types) may lose their locking effectiveness after initial use—inspect the prevailing torque feature and replace if compromised. Nylon insert nuts should typically be replaced after removal as thermal and mechanical cycling degrades the nylon ring.

Q: Are flange nuts suitable for outdoor applications?

A: Yes, flange nuts are excellent for outdoor applications when manufactured from appropriate materials with suitable surface treatments. For outdoor use, specify:

- 304 or 316 stainless steel for corrosion resistance

- Hot-dip galvanised carbon steel for structural applications

- Zinc-nickel or zinc flake coatings for automotive/industrial outdoor use

Avoid plain carbon steel with minimal coating in outdoor environments as corrosion will compromise performance.

Q: What size flange nuts does Trojan Special Fasteners manufacture?

A: Trojan Special Fasteners manufactures flange nuts from M3 to M52 in metric threads, 2BA to 2" in Imperial BSW/BSF threads, and #8 to 2.1/4" in Unified UNC/UNF threads. We also produce non-standard sizes, special thread forms (left-hand, multi-start, Acme, etc.), and completely bespoke designs to customer specifications.

Q: Can flange nuts be made with left-hand threads?

A: Yes, Trojan Special Fasteners manufactures left-hand threaded flange nuts for applications requiring reverse-rotation security (e.g., rotating machinery, bicycle pedals, propeller shafts). Left-hand threads are designated with "LH" suffix (e.g., M12 x 1.75 LH).

Q: Do you manufacture flange nuts to custom drawings?

A: Yes, Trojan Special Fasteners specialises in bespoke fastener manufacturing. We produce flange nuts to customer-supplied drawings and specifications including non-standard dimensions, special materials, unique flange geometries, combination features (e.g., flange + nylon insert + serrations), and proprietary designs. Our engineering team collaborates with clients to optimise designs for manufacturability and performance.

Q: What is the maximum temperature rating for nylon insert locking flange nuts?

A: Nylon 6.6 (polyamide) inserts have a maximum continuous service temperature of approximately 120°C (248°F). Above this temperature, the nylon begins to soften and lose its locking effectiveness. For higher temperature applications (>120°C), specify all-metal prevailing torque locking flange nuts which rely on deformed threads rather than polymer inserts.

Q: Can flange nuts be supplied with certification?

A: Yes, Trojan Special Fasteners provides material certification and test documentation as required. Available certificates include:

- Material test certificates (3.1 per EN 10204)

- Chemical composition analysis

- Mechanical property test results

- Dimensional inspection reports

- Traceability documentation with heat/lot codes

Certification requirements should be specified at the time of quotation.

Q: What surface treatments are recommended for marine environments?

A: For marine applications, we recommend:

- Submerged/splash zone: 316 stainless steel (no coating needed) or bronze

- Above waterline: 304 or 316 stainless steel, hot-dip galvanised carbon steel

- Coastal (salt air exposure): 316 stainless steel, zinc-nickel plated carbon steel, or 304 stainless with additional coating

Avoid plain zinc plating and aluminium in saltwater environments due to galvanic corrosion and rapid degradation.

Q: How do I determine the correct torque value for installation?

A: Installation torque depends on:

- Thread size and pitch

- Material grade (8.8, 10.9, stainless, etc.)

- Lubrication condition (dry, oiled, anti-seize, etc.)

- Required preload (clamping force)

- Friction coefficient of surface treatment

Consult torque reference charts specific to your fastener grade and lubrication condition. As a general rule, lubricated assemblies require approximately 20-30% less torque than dry assemblies to achieve equivalent preload. For critical applications, use calibrated torque wrenches and follow documented tightening procedures.

Q: Can Trojan Special Fasteners test prevailing torque on locking flange nuts?

A: Yes, we offer prevailing torque testing services. Supply us with the mating threaded component (bolt, stud, or internally threaded part) and we will conduct installation/removal torque tests to verify locking performance meets your specifications. Test results can be documented and certified as required.

Q: What is the lead time for bespoke flange nuts?

A: Lead times vary depending on order quantity, material availability, and manufacturing complexity. Standard catalogue items in common materials may be available from stock. Bespoke designs typically require:

- 1-2 weeks: Engineering review and quotation

- 2-4 weeks: Prototype/first article production

- 3-6 weeks: Full production batches

Contact our sales team for specific lead time estimates based on your requirements.

Q: What is the difference between a flange nut and a collar nut?

A: A flange nut has a wide circular flange at the base that extends outward beyond the hexagon body, providing maximum bearing surface area. A collar nut has a cylindrical collar section where the diameter is equal to or less than the across-flats dimension of the hexagon, providing a more compact profile. Flange nuts are better for maximum load distribution, whilst collar nuts are ideal for confined spaces or applications requiring alignment guidance from the collar.

Q: Can flange nuts be zinc plated?

A: Yes, carbon steel flange nuts can be zinc plated for corrosion protection. We offer clear zinc, yellow zinc, and black zinc plating options. Zinc plating typically provides 96-720 hours salt spray resistance depending on thickness. For enhanced corrosion protection, we recommend zinc-nickel plating (720+ hours) or hot-dip galvanising for outdoor structural applications. Stainless steel flange nuts do not require plating due to their inherent corrosion resistance.

Q: What thread types can you manufacture?

A: Trojan Special Fasteners manufactures flange nuts with metric threads (M3-M52), Imperial BSW/BSF threads (2BA-2"), and Unified UNC/UNF threads (#8-2.1/4"). We also produce special thread forms including left-hand threads, fine pitch threads, Acme threads, Buttress threads, square threads, multi-start threads, and completely custom thread profiles to customer specifications.

Q: Do you offer minimum order quantities?

A: Minimum order quantities vary depending on material, size, and specification complexity. For standard sizes in common materials (carbon steel, 304 stainless), we can accommodate small batch orders. Bespoke designs or exotic materials may require higher minimum quantities due to material procurement and setup costs. Contact our sales team to discuss your specific requirements—we're flexible and work with customers from prototype quantities through to high-volume production.

Q: Can you match an existing nut without a drawing?

A: Yes, if you can provide a physical sample, our engineering team can reverse-engineer the dimensions and produce matching flange nuts. We'll measure all critical dimensions (thread size, pitch, across-flats, flange diameter, height) and create a detailed drawing for your approval before manufacturing. For best results, provide 2-3 sample nuts to ensure accuracy and account for any manufacturing variations in the original parts.

Q: What is the difference between Grade 8.8 and Grade 10.9 nuts?

A: Grade 8.8 nuts have a minimum proof stress of 800 N/mm² and are suitable for general industrial applications with Grade 8.8 bolts. Grade 10.9 nuts have a minimum proof stress of 1000 N/mm² and are required for high-strength applications using Grade 10.9 or 12.9 bolts. Using Grade 8.8 nuts with Grade 10.9+ bolts may result in nut thread stripping before the bolt reaches full preload. Always match nut grade to bolt grade for balanced joint strength.

Q: Can flange nuts be passivated?

A: Yes, stainless steel flange nuts can be passivated to enhance their natural corrosion resistance. Passivation is a chemical treatment that removes free iron contamination from the surface and promotes formation of a chromium oxide passive layer. This is particularly important after machining operations. We can provide passivation per ASTM A967 or AMS 2700 specifications. Carbon steel flange nuts cannot be passivated as they lack sufficient chromium content.

Q: What is the torque-tension relationship for flange nuts?

A: The relationship between installation torque and bolt tension (preload) depends on multiple variables including thread pitch, material grade, surface treatment, lubrication, and friction coefficient. As a general approximation: Torque (N⋅m) = K × d × F, where K is the friction coefficient (typically 0.15-0.20 for dry assemblies, 0.10-0.15 for lubricated), d is the nominal bolt diameter (mm), and F is the desired preload (kN). For critical applications, use calibrated torque wrenches and follow documented tightening procedures with appropriate K-factor for your specific conditions.

Q: Do flange nuts meet automotive industry standards?

A: Yes, we manufacture flange nuts to automotive industry specifications including ISO, DIN, and proprietary OEM standards. For automotive applications, we typically supply Grade 10.9 or 12.9 carbon steel nuts with zinc-nickel or zinc-flake coatings for corrosion protection and no hydrogen embrittlement risk. We can provide PPAP documentation (Production Part Approval Process), material certifications, and dimensional inspection reports as required by automotive quality management systems.

Q: Can you manufacture flange nuts in small sizes for electronics?

A: Yes, we manufacture small-diameter flange nuts from M3 upwards, which are commonly used in electronics assembly, instrumentation, and precision equipment. Popular sizes for electronics include M3, M4, M5, and M6 in materials such as brass (for electrical conductivity), aluminium (for weight savings), and stainless steel (for corrosion resistance). We maintain tight tolerances essential for automated assembly and can provide clean, burr-free parts suitable for circuit board mounting.

Q: What is a serrated flange nut and when should I use one?

A: A serrated flange nut has radial teeth or serrations on the underside of the flange bearing surface. These serrations bite into the substrate during tightening, creating mechanical interlock and increased friction that resists vibration-induced loosening. Use serrated flange nuts in moderate-vibration applications, on softer materials (aluminium, plastics), or where cost-effective locking is needed without nylon inserts. Avoid serrated nuts on decorative surfaces, painted finishes, or very hard materials where the serrations cannot penetrate effectively.

Q: How does bar turning differ from cold forming for flange nuts?

A: Bar turning (our method) machines flange nuts from solid bar stock using CNC lathes, offering superior dimensional accuracy, tighter tolerances, excellent surface finish, and ability to produce complex geometries and non-standard sizes. Cold forming stamps nuts from wire or bar using dies under high pressure—it's faster for very high volumes but limited to standard sizes with looser tolerances. Bar turning excels for precision applications, bespoke designs, harder materials, and smaller production batches where quality outweighs pure volume efficiency.

Q: Can you provide material test certificates?

A: Yes, we provide material test certificates (also called mill test certificates or 3.1 certificates per EN 10204) documenting chemical composition, mechanical properties (tensile strength, yield strength, hardness), and heat/lot traceability. Certificates are available for most materials at a nominal surcharge. For critical applications (aerospace, medical, nuclear, pressure vessels), we can arrange 3.1 certification with full traceability from raw material supplier through finished component. Specify certification requirements when requesting quotation.

Q: What is the difference between UNC and UNF threads?

A: UNC (Unified National Coarse) threads have a larger pitch (fewer threads per inch) providing faster assembly, better performance in softer materials, and improved vibration resistance. UNF (Unified National Fine) threads have a smaller pitch (more threads per inch) offering greater thread engagement, higher tensile stress area, better locking performance, and suitability for precision adjustments. For example, 1/2" UNC has 13 threads per inch whilst 1/2" UNF has 20 threads per inch. Choose UNC for general applications, UNF for precision or high-strength requirements.

Q: Can flange nuts be anodised?

A: Aluminium flange nuts can be anodised to create a hard, durable, corrosion-resistant surface. Anodising creates an aluminium oxide layer that can be dyed various colours (clear, black, red, blue, gold) for identification or aesthetic purposes. The anodised layer is typically 5-25 microns thick and provides excellent wear resistance. Anodising is not applicable to steel, brass, or bronze nuts—these materials require different surface treatments such as plating, painting, or powder coating.

Q: What are the benefits of stainless steel over carbon steel?

A: Stainless steel flange nuts offer superior corrosion resistance without requiring additional surface treatments, making them maintenance-free in most environments. They're ideal for food processing, marine, chemical, and architectural applications. However, stainless steel has lower strength than heat-treated carbon steel (A2-70 stainless ≈ Grade 5.8 carbon steel), costs 3-5× more, and can suffer galling (thread seizure) during installation. Carbon steel with appropriate plating offers higher strength and lower cost but requires surface protection and may not be suitable for aggressive environments.

Q: Can you manufacture flange nuts with inspection holes?

A: Yes, we can incorporate inspection holes, witness holes, or tell-tale holes into flange nut designs. These features allow visual verification of thread engagement, bolt length, or preload indication without disassembling the joint. Inspection holes are commonly used in critical applications (aerospace, pressure vessels, structural connections) where joint integrity must be verified. Provide your dimensional requirements and we'll incorporate the feature into the manufacturing process.

Q: What is the recommended torque sequence for multiple flange nuts?

A: For assemblies with multiple flange nuts (such as flange joints, cylinder heads, or structural connections), follow a star or cross pattern tightening sequence starting from the centre and working outward. This ensures even load distribution and prevents warping. Use a multi-stage tightening procedure: first pass at 30% of final torque, second pass at 60%, third pass at 100%. Allow time between stages for joint relaxation. For critical applications, re-torque after initial operation or thermal cycling to account for embedment relaxation and settling.

Q: Do you offer custom flange diameters?

A: Yes, we manufacture flange nuts with custom flange diameters to suit specific applications. Standard flange diameters are typically 1.5-2.0× the across-flats dimension, but we can produce larger or smaller flanges as required. Larger flanges provide greater load distribution for soft materials or uneven surfaces, whilst smaller flanges reduce the radial footprint for space-constrained installations. Provide your required flange diameter and we'll verify manufacturability and quotation accordingly.

Q: Can flange nuts be supplied with locking patches or adhesives?

A: Yes, we can apply pre-applied adhesive patches (such as Nylok, Vibra-Tite, or equivalent) to flange nut threads. These microencapsulated adhesive patches activate during installation, creating a threadlocking effect that prevents loosening under vibration. Pre-applied patches offer convenience (no separate threadlocker application needed), clean assembly, consistent performance, and no mess compared to liquid threadlockers. They're suitable for temperatures up to 150°C and provide medium-strength locking that can be disassembled with hand tools.

Q: What flange thickness should I specify?

A: Standard flange thickness is defined by the applicable standard (ISO, DIN, ASME) and typically ranges from 1.5-4.0mm depending on nut size. Thicker flanges provide greater rigidity and load distribution but increase overall nut height and material cost. Thinner flanges reduce profile but may deform under high loads. For custom applications, consider substrate hardness (thicker flanges for softer materials), clamping loads (higher loads require thicker flanges), and clearance constraints (limited height requires thinner flanges). Our engineering team can recommend optimal flange thickness for your application.

Q: Can you manufacture flange nuts from customer-supplied material?

A: We can manufacture flange nuts from customer-supplied bar stock in certain circumstances, particularly for exotic materials or when the customer has existing material inventory. The material must be supplied in appropriate bar stock diameter with sufficient length for our turning operations. We'll require material certification and may perform incoming inspection to verify properties. Lead times may be shorter when material is customer-supplied, but pricing reflects machining operations only. Contact our sales team to discuss specific arrangements and technical requirements.

Quality Assurance and Inspection

Trojan Special Fasteners maintains rigorous quality control throughout the manufacturing process:

Incoming Material Inspection

All raw materials are verified for chemical composition, mechanical properties, and dimensional conformance before entering production. Material certificates are reviewed and archived for traceability.

In-Process Inspection

First-off component inspection verifies dimensional accuracy before production runs commence. Statistical process control (SPC) monitors critical dimensions throughout production. Thread gauges (Go/No-Go) verify internal thread geometry and pitch accuracy.

Final Inspection

100% visual inspection for cosmetic defects, burrs, and surface finish quality. Sample-based dimensional inspection using calibrated measuring equipment (micrometers, height gauges, thread gauges, optical comparators). Surface treatment thickness measurement (X-ray fluorescence for plating thickness). Prevailing torque testing for locking variants.

Certification and Documentation

Material test certificates, dimensional inspection reports, and surface treatment certifications are provided as specified. Full traceability from raw material heat lot through finished component batch.

Environmental Considerations and Sustainability

Trojan Special Fasteners is committed to environmentally responsible manufacturing:

Material Efficiency

Bar turning manufacturing minimises material waste compared to forging and casting processes. Machining swarf (metal chips) is collected and recycled through certified metal recycling partners.

Surface Treatment

We work with surface treatment suppliers who comply with REACH regulations and RoHS directives, eliminating hazardous substances such as hexavalent chromium from plating processes.

Energy Efficiency

Modern CNC turning centres operate with optimised cutting parameters and energy-efficient servo drive systems, reducing electrical consumption per component.

Packaging

Fasteners are packaged using recyclable materials wherever possible. Bulk packaging minimises waste compared to individual component packaging.

Ordering Information

To request a quotation for flange or collar nuts, please provide:

- Thread size and type (metric, Imperial, Unified)

- Thread pitch (fine or coarse)

- Material specification

- Surface treatment/coating

- Standard reference (ISO, DIN, ASME, etc.) or customer drawing

- Quantity required

- Required certification and documentation

- Delivery timescale

Contact Trojan Special Fasteners:

Our technical sales team is available to discuss your flange and collar nut requirements, provide application guidance, and assist with material and specification selection.

Visit: www.trojansf.co.uk/contact-us

Email: sales@trojansf.co.uk

Phone: 0121 789 8586

Related Products and Services

Explore our full range of precision-manufactured fasteners:

- Hexagon Nuts: Standard hex nuts in all sizes and materials

- Nyloc Nuts: Nylon insert locking nuts for vibration resistance

- Castle Nuts: Castellated nuts for split pin locking

- Slotted Nuts: Axially and radially slotted nut variants

- Weld Nuts: Projection welding and resistance welding nut types

- Wing Nuts: Hand-tightenable fasteners for tool-free assembly

- Cap Nuts: Acorn nuts and domed cap nuts for aesthetic finishing

- Coupling Nuts: Threaded rod and stud connectors

- Square Nuts: Four-sided nuts for high-torque applications

- Precision Turned Parts: Bespoke CNC machined components

- Polygon Turning Services: Multi-sided precision turning capabilities

Technical Resources:

- Fastener Standards Database: Comprehensive reference for ISO, DIN, ASME specifications

- Material Selection Guide: Choose the optimal material for your application

- Torque Specification Charts: Installation torque reference tables

- Thread Reference Guide: Metric, Imperial, and Unified thread tables

- Coating Comparison Guide: Surface treatment performance comparison

Case Studies and Applications

Case Study 1: Automotive Suspension Assembly

Challenge: Automotive manufacturer required high-volume supply of M12 x 1.75 Grade 10.9 flange nuts with zinc-nickel coating for suspension component assembly. Previous supplier's inconsistent flange thickness caused automated tooling issues.

Solution: Trojan Special Fasteners produced flange nuts to ISO 4161 with tightened flange thickness tolerance (±0.1mm vs. ±0.3mm standard). Statistical process control ensured consistent dimensional accuracy across 500,000-piece annual volume.

Result: Assembly line downtime eliminated. Client achieved 15% reduction in assembly time due to improved part consistency and elimination of washer handling.

Case Study 2: Offshore Wind Turbine Installation

Challenge: Renewable energy contractor needed large-diameter (M36-M48) stainless steel 316 flange nuts for turbine tower flange connections in North Sea offshore wind farm. Standard availability was insufficient for project timeline.

Solution: Trojan Special Fasteners manufactured A4-80 grade stainless steel flange nuts to DIN 6923 in sizes M36, M42, and M48 with hot-dip galvanised coating over stainless steel (duplex coating system) for maximum corrosion protection.

Result: Delivered 2,400 precision flange nuts within 6-week lead time. Fasteners have performed reliably in harsh marine environment for 5+ years with no corrosion-related issues.

Case Study 3: Medical Device Manufacturing

Challenge: Medical equipment manufacturer needed small-diameter (M4, M5) 316L stainless steel flange nuts with electropolished finish for surgical instrument assembly. Strict cleanliness and traceability requirements per ISO 13485.

Solution: Trojan Special Fasteners produced pharmaceutical-grade 316L stainless flange nuts with Ra <0.4μm electropolished surface finish. Full material traceability with 3.1 certification, lot coding, and cleanroom packaging provided.

Result: Components met stringent medical device regulatory requirements. Client approved Trojan as qualified fastener supplier for ongoing medical product lines.

Glossary of Technical Terms

Across Flats (A/F): The width measurement across the parallel faces of a hexagon nut, used to determine the correct spanner or socket size.

Bearing Surface: The underside face of the nut (or flange) that contacts the substrate material.

Class of Fit: Tolerance grade defining the clearance or interference between internal (nut) and external (bolt) threads. Common classes include 6H (nut) mating with 6g (bolt).

Coarse Thread: Standard thread pitch with larger pitch distance, providing faster assembly and better performance in softer materials.

Fine Thread: Reduced pitch distance providing greater thread engagement and better locking performance, commonly used in precision applications.

Flange Diameter: The external diameter of the circular flange washer section at the base of a flange nut.

Grade: Material strength classification (e.g., Grade 1, 5, 6, 8, 10, 12 for carbon steel; A2-70, A4-80 for stainless steel) indicating tensile and yield strength properties.

Major Diameter: The largest diameter of an internal thread (nut) measured across the thread crests.

Minor Diameter: The smallest diameter of an internal thread measured at the base of the thread roots.

Pitch: The axial distance between adjacent thread crests, measured in millimetres (metric) or threads per inch (Imperial/Unified).

Prevailing Torque: Resistance to rotation created by a locking feature (nylon insert, deformed threads) that provides vibration resistance.

Proof Load: Maximum load a fastener can withstand without permanent deformation, typically 85-90% of yield strength.

Thread Engagement: The axial length over which internal (nut) and external (bolt) threads overlap and engage.

Tensile Strength: Maximum stress a material can withstand before failure, measured in N/mm² or MPa.

Yield Strength: Stress level at which a material begins to deform plastically (permanently), measured in N/mm² or MPa.

Why Choose Trojan Special Fasteners for Flange and Collar Nuts?

Precision Bar Turning Expertise

Our advanced CNC turning centres deliver superior dimensional accuracy and surface finish quality compared to cold-formed or forged fasteners. Bar turning enables tight tolerances, complex geometries, and consistent quality across production batches.

Comprehensive Size Range

From miniature M3 fasteners to large M52 industrial nuts, we manufacture the complete spectrum of thread sizes in metric, Imperial, and Unified forms. Non-standard and special sizes are produced with the same precision as catalogue items.

Material Versatility

Our material expertise spans carbon steels, stainless steels, aluminium, brass, bronze, titanium, nickel alloys, and exotic materials. We source materials from approved suppliers with full traceability and certification.

Custom Design Capabilities

Our engineering team collaborates with clients to develop bespoke fastener solutions optimised for specific applications. From concept through production, we provide technical support, prototyping, and full-scale manufacturing.

Quality Assurance

ISO 9001 certified quality management systems ensure consistent product quality. Comprehensive inspection procedures, calibrated measuring equipment, and documented traceability provide confidence in every component.

UK-Based Manufacturing

Domestic manufacturing provides short lead times, responsive customer service, and support for local supply chains. Direct communication with our technical team ensures your requirements are clearly understood and accurately fulfilled.

Competitive Pricing

Efficient manufacturing processes and strategic material sourcing enable competitive pricing for both prototype quantities and high-volume production runs.

Technical Support

Our experienced team provides application guidance, material selection advice, standard interpretation, and installation recommendations to ensure optimal fastener performance in your specific application.

Get a Quote Today

Contact Trojan Special Fasteners to discuss your flange nut and collar nut requirements. Whether you need standard catalogue items or completely bespoke designs, our team is ready to provide expert guidance and competitive quotations.

Request a quote online: www.trojansf.co.uk/contact-us

Email technical enquiries: trojan.fasteners@gmai.com

Call our sales team: 0121 789 8586

Trojan Special Fasteners Ltd — Your trusted partner for precision-engineered fasteners.