Hex Nuts

Custom Hexagon Nut Manufacturing | Precision Bar-Turned Hex Nuts | Birmingham, UK

Trojan Special Fasteners Ltd manufactures precision hexagon nuts (hex nuts) to exacting specifications for engineering, construction, automotive, rail, aerospace, and industrial applications throughout the UK and internationally. As a specialist bespoke hex nut manufacturer based in Birmingham, we produce nuts from M3 to M52 in metric, 2BA to 2" in Imperial (BSW/BSF), and #8 to 2.1/4" in Unified (UNF/UNC) thread forms. Our CNC bar-turning capabilities ensure exceptional accuracy, consistency, and finish for both standard and non-standard specifications.

Key Capabilities:

- ISO 9001:2015 certified quality management

- Single prototype to batch production (1 to 10,000+ units)

- Over 31 years of precision fastener manufacturing experience

- Full material traceability and certification available

- Fast turnaround times for urgent orders

- In-house thread cutting, chamfering, and finishing operations

- Left-hand threads and oversize pitches available

What Are Hexagon Nuts?

Hexagon nuts, commonly called hex nuts, are six-sided internally threaded fasteners designed to mate with bolts, screws, or threaded studs. The hexagonal profile provides six flat surfaces (across flats) that allow standard spanners, wrenches, or sockets to apply torque for tightening or loosening. This six-sided geometry offers optimal tool engagement angles—particularly useful in confined spaces—whilst providing sufficient material strength to resist deformation under load.

The hexagon became the standard nut shape during the Industrial Revolution when Sir Joseph Whitworth standardised screw threads in the mid-19th century. Today, hex nuts remain the most widely used nut type globally due to their versatility, ease of manufacture, and mechanical efficiency.

Why Hexagon Nuts Have Six Sides

The six-sided design strikes an engineering balance between tool accessibility and structural integrity:

- 60-degree tool approach angles allow excellent access in tight assembly spaces

- Lower corner count (compared to octagonal or 12-point designs) reduces the risk of corner rounding under high torque

- Balanced stress distribution across six flats provides uniform clamping force

- Universal compatibility with standard metric and imperial spanners, sockets, and adjustable wrenches

Hexagon nuts with rounded or damaged corners become extremely difficult to remove, which is why the six-sided profile has proven optimal for industrial use for over 170 years.

Hex Nut Sizes We Manufacture

Trojan Special Fasteners machines hex nuts in an extensive range of sizes and thread forms:

Metric Sizes (ISO Thread)

- M3, M4, M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M20, M22, M24, M25, M26, M27, M28, M30, M32, M33, M34, M35, M36, M38, M39, M40, M42, M45, M48, M50, M52, M56

- Available in coarse pitch (standard), fine pitch, extra fine pitch, and special hard-to-find pitches

- Left-hand thread variants available across all sizes

- Oversize thread diameters for specific applications

Imperial Sizes (BSBrass, BSCy, CEI, BSPP, BSW, BSF, Whitform and BA Threads)

- British Standard Brass, British Standard Cycle, British Standard Parallel Pipe, British Standard Whitworth (BSW), British Standard Fine (BSF) and Whitform (55 degree): 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2"

- British Association (BA): 2BA to 10BA and larger

Unified Sizes (UNC, UNF, UNS, UN8, UN12, UNEF Threads)

- #8, #10, 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2", 2.1/4"

- Unified Extra Fine (UNEF) and special TPI (threads per inch) available

- Left-hand threads and oversize diameters manufactured to order

Special & Non-Standard Sizes

- Mixed thread forms (e.g., M20 metric one end, 1/2" UNF the other end—coupling nuts)

- Non-preferred sizes and obsolete thread forms

- Custom across-flats (AF) dimensions for specific spanner sizes

- Special thicknesses: full nuts, lock nuts, thin nuts, panel nuts, extra-thick heavy hex nuts

- Drawing-specific dimensions for bespoke engineering applications

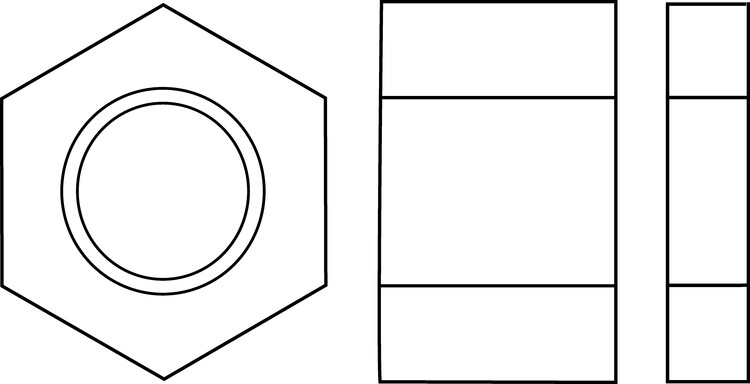

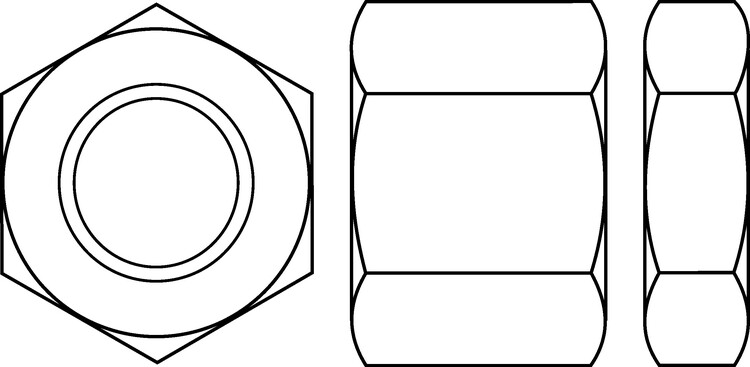

What is a single-chamfered nut?

A single chamfered nut is a type of nut that has one end that is angled or beveled and the other is unchamfered and also referred to as the bearing side of the nut. These nuts are also sometimes referred to as full-bearing nuts. The face of one side of the nut is typically angled by 30 degrees. These nuts are not reversible, as in there is only one way to correctly apply the nut to a joint.

The unchamfered or full-bearing side of the nut is the one that is typically applied to the joint. The larger surface area increases friction and should reduce loosening.

Most Whitworth and BSF full nuts are single chamfered, but these are also available as double-chamfered nuts.

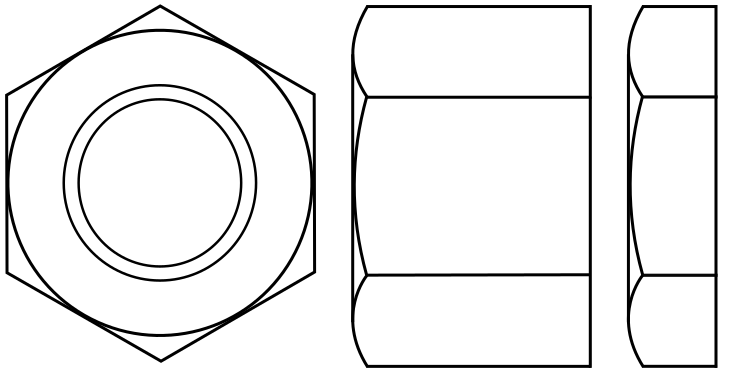

What is a double-chamfered nut?

A double chamfered nut is a type of nut has a 30 degree chamfer on both ends of a nut. Most nuts are typically double-chamfered and so they are reversible and either side can be applied to a joint.

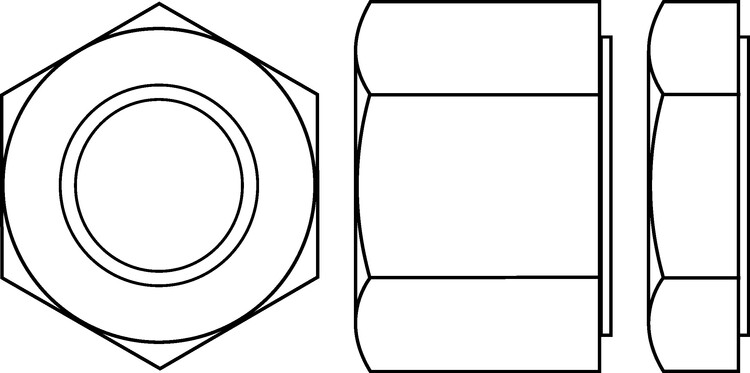

Washer-Faced Nuts

Washer-faced nuts (also called washer-face nuts or integral washer nuts) are hexagon nuts with one face machined to create a flat, raised circular bearing surface—essentially an integral washer formed into the nut body. This washer face sits proud of the chamfered edges, providing a larger, flat contact area against the joint surface.

Engineering Benefits:

1. Increased Bearing Surface Area

The integral washer face provides significantly more surface contact than a standard chamfered nut, distributing clamping loads over a wider area. This prevents localised stress concentrations that can damage substrates.

2. Load Distribution on Soft Materials

When fastening thin sheet metal, plastics, composites, timber, or other relatively soft materials, the increased bearing area prevents the nut from crushing, deforming, or pulling through the material under clamping force.

3. Enhanced Joint Strength

By distributing loads evenly, washer-faced nuts increase the effective strength of bolted joints. The joint is less likely to fail due to substrate deformation or fastener pull-through.

4 . Reduced Surface Damage

The flat washer face spreads pressure, minimising indentation, cracking, or surface marring of painted, plated, or decorative finishes on the assembly.

5. Improved Friction and Resistance to Loosening

The larger flat surface creates more friction between nut and substrate compared to chamfered edges. This additional friction helps resist loosening from vibration—particularly important when used with spring washers or on applications without prevailing-torque lock nuts.

6. Eliminates Separate Washer Requirements

By incorporating the washer into the nut body, washer-faced nuts reduce assembly time, parts count, and inventory complexity. No need to handle and position separate flat washers during installation.

7. Better Alignment on Uneven Surfaces

The washer face bridges minor surface irregularities, providing more consistent clamping even on slightly uneven or textured surfaces such as cast components or forgings.

It's important to note that washer faced nuts should not be used in situations where a locknut is required, as they do not provide any locking mechanism. They also should not be used in applications that require a high level of precision, as the thickness of the washer face may not be consistent. Finally, they should not be used in corrosive environments as the washer face may not be corrosion resistant.

Common Applications:

Construction & Structural Engineering

- Steel framework connections where large clamping forces are applied

- Timber frame construction—distributes load on wood fibres

- Curtain wall and cladding systems—prevents damage to aluminium panels

- Roofing and façade fastening—weatherproofing integrity maintained

Heavy Machinery & Industrial Equipment

- Machine tool mounting—prevents crushing of machine beds

- Equipment foundations—distributes anchor bolt loads

- Conveyor systems—holds components on fabricated steel frames

- Hydraulic and pneumatic assemblies—seals against flat gasket surfaces

Automotive & Transportation

- Commercial vehicle chassis assemblies

- Trailer and caravan construction—protects aluminium and steel panels

- Agricultural machinery—high-torque fastening on fabricated components

- Railway rolling stock—bogie and underframe connections

Electrical & Telecommunications

- Switchgear and control panel mounting

- Antenna and mast installations—wind-load resistance

- Electrical enclosure assembly—prevents crushing of thin sheet steel

- Cable tray and conduit support brackets

Marine & Offshore

- Deck hardware mounting on fibreglass or timber

- Superstructure connections on aluminium vessels

- Porthole and hatch securing—distributes loads on thin hull sections

- Mast and rigging attachments

Design Considerations & When to Use:

Best Used When:

- Fastening to thin materials (<5mm sheet metal, thin wall sections)

- Substrates are soft or low-strength (timber, plastics, composites, aluminium)

- High clamping forces are required that might damage standard bearing surfaces

- Eliminating separate washers simplifies assembly or reduces costs

- Vibration resistance is needed but prevailing-torque lock nuts aren't suitable

- Surface finish must be protected from nut indentation

- Uneven or textured surfaces require load bridging

Avoid Using When:

- Prevailing-torque lock nuts (nyloc, all-metal lock nuts) are required—washer-faced nuts have no self-locking mechanism

- Precision height/thickness is critical—washer face thickness tolerance may affect stack-up dimensions

- Corrosive environments without appropriate coating—standard washer faces are typically uncoated mild steel and may corrode. Specify stainless steel or coated variants for corrosion resistance

- Very high-precision machined surfaces where the raised washer face prevents full nut-to-surface contact

- Applications requiring locking wire or split pins—castellated or slotted nuts are more appropriate

Types of Hexagon Nuts We Manufacture

Full Hex Nuts (Standard Nuts)

The most common hex nut type, featuring standard thickness (typically 0.8d to 1.0d, where d = nominal diameter). Full nuts provide maximum thread engagement and clamping strength. Available in:

- Single-chamfered (full-bearing): One face chamfered at 30°, opposite face flat (bearing surface). Common in BSW/BSF specifications. Non-reversible—bearing face must contact the joint surface for maximum friction and security.

- Double-chamfered: Both faces chamfered at 30°. Reversible design, standard for metric ISO nuts and Unified threads. Either face may contact the joint.

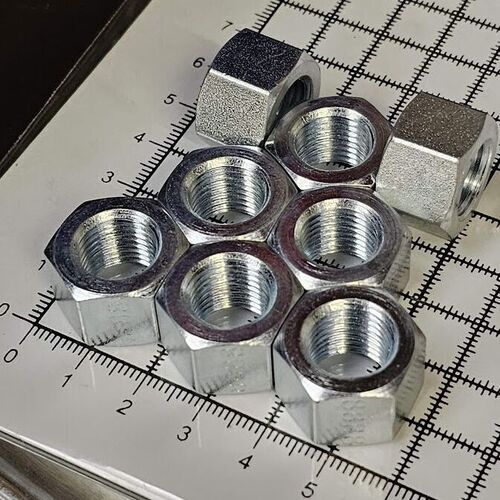

Heavy Hex Nuts

Heavy hex nuts feature increased across-flats dimensions and greater thickness than standard nuts of the same thread size. Benefits include:

- Greater thread engagement for higher load-bearing capacity

- Reduced nut expansion under torque due to increased wall thickness

- Structural applications such as steel construction, bridges, and heavy machinery

- Available to BS 1769 (Unified), BS EN 14399-4 (metric structural), DIN 6915 (metric), and BSW threads

Trojan manufactures heavy hex nuts to customer drawings or recognised standards for high-strength bolted connections.

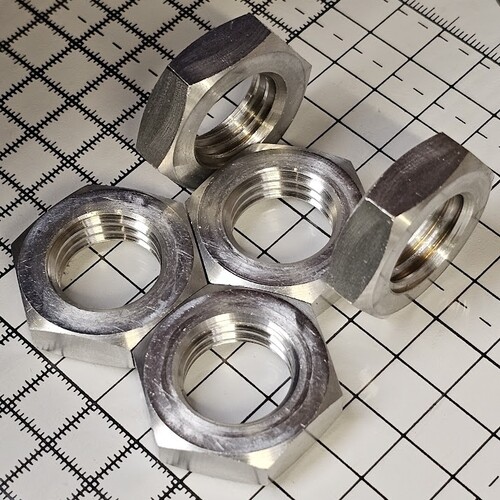

What are lock nuts?

Presently many people refer to locking nuts as 'lock nuts' - although this is not exactly correct.

Lock nuts are nuts, when used in pairs, can provide prevailing torque to 'lock' something in place. In essence, they are thinner nuts (typically 0.45d) and when another nut is tightened against it, as a pair, they provide an amount of prevailing torque to stop the nuts from loosening.

Lock nuts or jam nuts can be used where a low profile nut with a reduced thickness is required.

These nuts are also sometimes referred to as jam nuts or half nuts.

Common Uses:

- Locking adjustable components in position (e.g., threaded rod adjustments)

- Low-profile applications where reduced height is essential

- Secondary locking mechanism without thread-locking compounds

- Anti-vibration assemblies in machinery and automotive applications

Trojan Special Fasteners will manufacture nuts to standard or even thinner, whatever you require. A drawing is always best for a non-standard fastener but we're well-versed in figuring out your needs from basic dimensional data. These can be machined in various strengths, thicknesses, thread types as well as finishes to choose from.

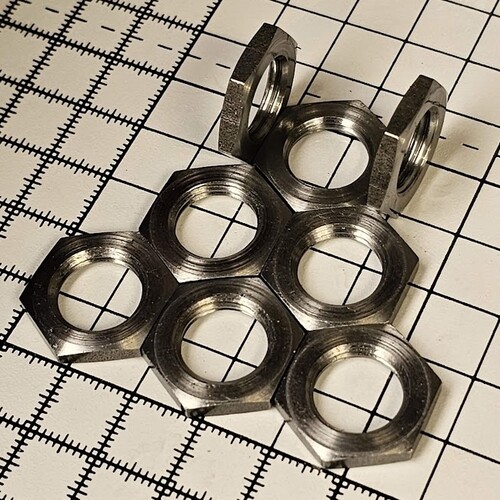

What are Panel Nuts?

Panel nuts are typically thinner than lock nuts or jam nuts. .

Panel nuts are used to attach small threaded components to, yes you guessed it a panel or enclosure. The type of components which are typically secured to said panels are things like switches, light bulb holders, potentiometers and other electrical components. Typically they have very fine thread pitches. As space is often limited because components are mounted close together and specific torque is not required, they usually have smaller across flats (spanner sizes) than regular nuts of that thread size.

An example of such a panel nut would be:

15/32x32tpi unified panel nut with a 9/16" across flat and 3/32" thickness.

- Very thin profile: typically 0.08" to 0.125" (2-3mm) thickness

- Fine thread pitches: accommodate small precision components

- Reduced across-flats: smaller spanner sizes to allow high component density

- Common in electronics: securing switches, potentiometers, sockets, lamp holders, and connectors

Typically a locking washer is used with the nut to try and reduce the chances of the nut loosening.

We can manufacture to the following specifications:

In addition to manufacturing to your drawing, sample or special instruction, we can manufacture nuts to the following specifications:

| Standard | Description |

|---|---|

| AS 1112.1 | Hexagon nuts, style 1, grade A & B |

| AS 1112.2 | Hexagon nuts, style 2, grade A & B |

| AS 1112.3 | Hexagon nuts, grade C |

| AS 1112.4 | Hexagon thin nuts (chamfered)Product grades A and B |

| AS 1252 | High Strength large hexagon nuts |

| AS 2451 | Hexagon nuts with BSW threads |

| AS 2465 | Hexagon nuts with Unified threads |

| ASME/ANSI B18.2.2 | Heavy hex nuts |

| ASME/ANSI B18.2. | Hex coupling nuts Table 13 |

| ASME/ANSI B18.2.2 | Hex flat jam nuts |

| ASME/ANSI B18.2.2 | Hex flat nuts and hex flat jam nuts Table 3 |

| ASME/ANSI B18.2.2 | Hex full nuts |

| ASME/ANSI B18.2.2 | Hex lock nuts |

| ASME/ANSI B18.2.2 | Hex nuts and hex jam nuts Table 4 |

| ASME/ANSI B18.2.2 | Hex thick nuts |

| ASME/ANSI B18.2.2 | Hex thick nuts Table 2 |

| ASME/ANSI B18.2.2 | Hexagon lock nuts -heavy duty |

| ASME/ANSI B18.2.4.1M | Hex full nuts style 1 |

| ASME/ANSI B18.2.4.2M | Hex nuts style 2 |

| ASME/ANSI B18.2.4.5M | Metric hex jam nuts |

| ASME/ANSI B18.2.4.5M | Metric hex thin nuts |

| ASME/ANSI B18.2.4.6M | Metric heavy hex nuts |

| ASME/ANSI B18.2.6 | Flat nuts and heavy hex flat jam nuts Table 9 |

| ASME/ANSI B18.2.6 | Heavy hex flat nuts Table 10 |

| ASME/ANSI B18.2.6 | Heavy hex nuts |

| BS 190 | Pre war Hexagon full nuts (Heavy series BSW or BSF) |

| BS 190 | Pre war Hexagon lock nuts (Heavy series BSW or BSF) |

| BS 1083 | Hexagon full nuts |

| BS 1083 | Hexagon lock nuts |

| BS 1768 | Hexagon full nuts - unified threads |

| BS 1768 | Hexagon lock nuts - unified threads |

| BS 1768 | Hexagon thick full nuts - unified threads |

| BS 1769 | Hexagon black full nuts - unified threads |

| BS 1769 | Hexagon heavy black full nuts - unified threads |

| BS 325 | Hexagon black full nuts |

| BS 3692 | Hexagon full nuts |

| BS 3692 | Hexagon lock nuts |

| BS 4190 | Hexagon thin lock nuts |

| BS 4395 | High strength large hex nuts |

| BS 916 | Hexagon black nuts |

| DIN 2510-5 | Reduced shank hexagon nuts |

| DIN 439-1 | Hexagon unchamfered thin lock nuts |

| Standard | Description |

|---|---|

| DIN 439-2 | Hexagon thin lock nuts |

| DIN 555 | Hexagon nuts |

| DIN 6915 | Heavy hex nuts |

| DIN 74361-2A | Hexagon wheel nuts |

| DIN 74361-2F | Hexagon conical wheel nuts |

| DIN 934 | Hexagon nuts |

| DIN 936 | Hexagon nuts |

| DIN 970 | Hexagon nuts |

| DIN 971-1 | Hexagon nuts, style 1 |

| DIN 971-2 | Hexagon nuts, style 2 |

| EN 14399-3 | High strength nuts for preloading assemblies HR system |

| EN 14399-4 | High strength nuts for preloading assemblies HV system |

| EN 14399-7 | High strength nuts for preloading assemblies HR system |

| EN 24035 | Hexagon thin nuts |

| EN 28673 | Hexagon nuts, style 1 |

| IFI 128 | Hexagon coupling nuts |

| ISO 13754 | Hexagon nuts |

| ISO 4032 | Hexagon nuts, style 1 |

| ISO 4033 | Hexagon nuts, style 1 |

| ISO 4034 | Hexagon nuts |

| ISO 4035 | Hexagon chamfered thin nuts |

| ISO 4036 | Hexagon unchamfered thin nuts |

| ISO 4775 | Heavy hexagon nuts |

| ISO 7413 | Galvanised hexagon nuts tapped oversize |

| ISO 7414 | Heavy hexagon nuts |

| ISO 7417 | Galvanised hexagon nuts tapped oversize |

| ISO 8673 | Hexagon nuts |

| ISO 8674 | Hexagon nuts |

| ISO 8675 | Hexagon thin lock nuts |

| NF E25-401 | Hexagon nuts, style 1 |

| NF E25-402 | Hexagon Nuts |

| NF E25-405-1 | Hexagon chamfered thin lock nuts |

| NF E25-405-2 | Hexagon unchamfered thin lock nuts |

| NF E25-407 | Hexagon nuts, style 2 |

| NF E25-451 | Hexagon nuts, style 1 |

| NF E25-452 | Hexagon nuts, style 2 |

| NF E25-453 | Hexagon chamfered thin nuts |

| UNI 5587 | Hexagon Nuts |

| UNI 5588 | Hexagon Nuts |

| UNI 5589 | Hexagon Nuts |

| UNI 5713 | Heavy hexagon nuts |

Materials & Specifications:

Trojan Special Fasteners manufactures washer-faced hex nuts in:

- Carbon steels: EN1A (230M07), EN8 (080M40) for general industrial use

- Stainless steels: 303, 304, 316, A2, A4 for corrosive environments

- Alloy steels: EN24 (817M40) for high-strength structural applications

- Non-ferrous: Brass, aluminium, bronze, aluminium bronze, nickel ali bronze for specialised applications

Surface Finishes:

- Bright zinc plating (clear, yellow, black)

- Hot-dip galvanising (excellent corrosion protection)

- Zinc-nickel or zinc-flake coatings

- Self-colour (as-machined)

- Customer-specified coatings

Thread Forms:

- Metric ISO: M8 to M52 (coarse, fine, extra-fine pitch)

- Unified: 1/4" to 2.1/4" (UNC, UNF, UNEF)

- Imperial: 1/4" BSW/BSF to 2" BSW/BSF

- Special threads to customer specification

Standards & Specifications:

Washer-faced nuts are manufactured to:

- Customer drawings and specifications

- BS EN ISO standards (with washer face modification)

- DIN equivalents with washer face

- ANSI/ASME standards with washer face

- Bespoke dimensions—we can machine any washer face diameter, thickness, and across-flats combination

Typical Dimensional Parameters:

- Washer face diameter: 1.5× to 2.0× across-flats dimension

- Washer face thickness: 0.5mm to 2.5mm (depending on nut size)

- Flatness tolerance: Typically ±0.1mm

- Perpendicularity: Within 1° of thread axis

Quality & Traceability:

All washer-faced nuts manufactured by Trojan Special Fasteners include:

- First article inspection available

- Dimensional verification reports

- Material certification (EN 10204 3.1 or 3.2 certificates)

- Full traceability from raw material to finished part

- ISO 9001:2015 quality management throughout production

Ordering Information:

When requesting a quotation for washer-faced hex nuts, please provide:

- Thread size and pitch (e.g., M16×2.0, 1/2" UNF, 3/8" BSW)

- Across-flats dimension (standard or custom)

- Overall nut thickness/height

- Washer face diameter

- Washer face thickness/height

- Material specification

- Surface finish or coating

- Quantity required

- Any applicable standards or drawing references

Alternatives & Related Products:

If washer-faced nuts don't suit your application, consider:

- Flange nuts: Integral flange provides similar load distribution with circular geometry

- Hex nuts with separate flat washers: Greater flexibility in washer size and material

- Nyloc washer-faced nuts: Combine load distribution with prevailing-torque locking (custom manufacture)

- Heavy hex nuts: Greater thickness without washer face—higher strength applications

Castle nuts and slotted hex nuts feature radial slots (typically 6 slots at 60° intervals) that accommodate split pins, cotter pins, or lock wire for positive locking.

- Castle nuts: Have a reduced-diameter cylindrical extension above the hex body containing the slots

- Slotted nuts: Slots cut directly into the top of the hex body, no extended section

- Common in safety-critical applications: aircraft, automotive suspension, machinery with rotating parts

All-Metal Prevailing Torque Lock Nuts

We manufacture distorted-thread and elliptical-form lock nuts that provide mechanical resistance to loosening without nylon inserts. Suitable for high-temperature environments and repeated assembly/disassembly cycles.

Nylon Insert Lock Nuts (Nyloc Nuts)

Available in low to moderate temperature applications (typically up to 120°C). The nylon insert creates friction against bolt threads to resist loosening.

Frequently Asked Questions (FAQ)

Thread Forms & Compatibility

What's the difference between a metric hex nut and a Unified hex nut?

Metric hex nuts use ISO metric threads (e.g., M12×1.75), where the thread is specified in millimetres with pitch in mm. Unified hex nuts use inch-based threads measured in TPI (threads per inch), such as 1/2"-13 UNC. The two systems are not interchangeable—always match nut and bolt thread forms. The fundamental difference lies in the thread profile geometry: metric threads use a 60° symmetrical profile with flat crests and roots defined by ISO 68-1, whilst Unified threads also use a 60° angle but with different tolerances and crest/root radii defined by ASME B1.1. Attempting to thread a metric bolt into a Unified nut (or vice versa) will result in cross-threading, damaged threads, and joint failure.

Can you make hex nuts with mixed threads?

Yes. Coupling nuts (also called barrel nuts or connector nuts) can have different threads on each end—for example, M20×2.5 metric on one side and 1/2" UNF on the other. These are commonly used to adapt between metric and imperial equipment, or left-hand/right-hand turnbuckle assemblies. We can also manufacture nuts with metric on one end and BSW/BSF on the other, or any combination you require. The nut body length is extended to provide sufficient thread engagement on both ends, and we carefully control the thread start positions to ensure both threads are concentric and square to the nut axis. Common applications include retrofitting metric components to imperial machinery, connecting mixed-standard piping systems, and adapting vintage equipment to modern fasteners.

What's the difference between UNC, UNF, and UNEF threads?

UNC (Unified Coarse), UNF (Unified Fine), and UNEF (Unified Extra Fine) refer to different thread pitches in the Unified thread system. UNC has fewer threads per inch and is used for general applications where rapid assembly and resistance to damage are priorities. For example, 1/2" UNC has 13 TPI. UNF has more threads per inch, providing finer adjustment and greater tensile stress area—1/2" UNF has 20 TPI. UNEF has even finer pitches for precision applications, vibration resistance, and thin-wall sections—1/2" UNEF has 28 TPI. Finer threads provide better resistance to loosening from vibration but are more susceptible to damage and cross-threading. We manufacture hex nuts in all three pitches and more across our full size range.

Are Whitworth (BSW) and BSF threads still used today?

Yes, particularly in heritage applications, classic vehicles, vintage machinery, railway restoration, and older British-manufactured equipment. BSW (British Standard Whitworth) uses a 55° thread angle with rounded crests and roots, quite different from the 60° angle of metric and Unified threads. BSF (British Standard Fine) uses the same 55° profile but with finer pitches. Many classic motorcycles (pre-1970s British bikes), vintage cars, steam engines, textile machinery, and heritage railways require BSW/BSF fasteners. We specialise in manufacturing these obsolete thread forms from 2BA up to 2" diameter, both in coarse (BSW) and fine (BSF) pitches. We can also manufacture to BS 1083:1965 (now withdrawn) for authentic restorations.

What are BA (British Association) threads?

BA threads are a small-diameter thread form originally developed for precision instruments, scientific equipment, and electrical applications. The thread series runs from 0BA (largest, approximately 6mm) down to 25BA (extremely fine, approximately 0.25mm). BA threads use a 47.5° thread angle, making them incompatible with metric or Unified threads. Today, BA threads are primarily found in vintage electronics, telegraph equipment, railway signalling, clock mechanisms, and scientific instruments from the 19th and early 20th centuries. We manufacture BA hex nuts from 2BA to 10BA and can source or manufacture larger sizes on request. Common applications include restoration of vintage radio equipment, antique clock repair, and heritage electrical switchgear.

Can metric and imperial spanners be used interchangeably on hex nuts?

Generally no, though some sizes are close enough to appear interchangeable. For example, a 13mm spanner is very close to 1/2" (12.7mm) and might work in an emergency, but this practice risks rounding the nut corners. Metric spanners are sized in millimetres (8mm, 10mm, 13mm, 17mm, etc.) whilst imperial spanners use fractional inches (5/16", 3/8", 7/16", 1/2", etc.) or AF (across flats) sizes. Using the wrong spanner can damage the hex flats, making the nut impossible to remove without destructive methods. Always use the correct spanner size for the nut specification. We can manufacture custom across-flats dimensions if you need compatibility with specific tooling.

What does "2BA" or "4BA" mean?

BA refers to British Association thread sizes, a numbered system where lower numbers indicate larger diameters. 2BA has a major diameter of approximately 4.7mm, whilst 4BA is approximately 3.6mm. The system runs from 0BA (largest, 6mm) through to very fine sizes like 16BA and beyond. BA threads were standardised in 1884 and widely used in British electrical and precision engineering. Unlike metric (which uses diameter in mm) or Unified (which uses fractions of an inch), BA uses an arbitrary numbering system. Each BA size has a defined major diameter, pitch, and thread form (47.5° angle). We can manufacture hex nuts from 2BA, 1BA and 0BA for restoration or repair projects.

Manufacturing & Materials

What does "single-chamfered" mean on a hex nut?

A single-chamfered (or full-bearing) nut has one face chamfered at 30° and one flat bearing face. The bearing face provides maximum surface contact for better friction and reduced loosening. These nuts are not reversible—only the bearing face should contact the joint surface. Common in Whitworth (BSW/BSF) specifications, particularly to BS 1083:1965 (now withdrawn but still widely referenced for heritage applications).

The unchamfered bearing face typically has a larger contact area, increasing friction between nut and substrate, which helps prevent loosening under vibration. The chamfered face allows the nut to be easily started on the thread. When installing single-chamfered nuts, always ensure the flat (unchamfered) bearing face contacts the joint surface—installing backwards significantly reduces clamping effectiveness and friction resistance.

Most current metric standards (BS EN ISO 4032, BS EN ISO 4033, etc.) specify double-chamfered nuts as standard, but single-chamfered variants are available and remain common in Imperial and Whitworth thread applications.

What materials are best for corrosion-resistant hex nuts?

Material selection depends on the specific corrosive environment. For marine/coastal environments, 316 stainless steel (marine grade) or bronze provides excellent chloride resistance. For chemical exposure, 316L stainless steel or specialist alloys offer superior protection. For outdoor/weather exposure, hot-dip galvanised carbon steel or 304 stainless steel performs well. For detailed material specifications and recommendations, please see our dedicated Materials page. We can advise on material selection based on your specific environmental conditions, operating temperature, and required service life.

What's the difference between free-cutting steel and standard steel for hex nuts?

Free-cutting steels (such as EN1APb/230M07Pb) contain sulphur or lead additions that improve machinability, allowing faster cutting speeds, better surface finish, and longer tool life. This makes them ideal for high-volume production of nuts where strength requirements are moderate. Standard steels (such as EN8/080M40) have higher tensile strength and better mechanical properties but are harder to machine, increasing production costs. For most general-purpose hex nuts, free-cutting EN1A provides an excellent balance of manufacturability and performance. For high-strength applications (structural nuts, heavy loads, impact resistance), we can use L7/B7, EN19T or EN24T or alloy steels despite the increased machining difficulty.

Can you supply hex nuts in aluminium, and what grades do you offer?

Yes, we machine aluminium hex nuts in several grades including 6082-T6 (general engineering), 6061-T6 (aircraft-quality), 2014-T6 (aerospace structural), and 7075-T6 (premium aerospace grade). Aluminium nuts are typically 65-70% lighter than steel equivalents, making them ideal for weight-critical applications like motorsport, aerospace, and drone construction. However, aluminium is softer than steel, so care must be taken not to over-torque as threads can strip. We can anodise aluminium nuts for improved wear resistance and corrosion protection. Aluminium nuts are unsuitable for high-temperature applications above 150°C as the alloy loses strength with heat.

Coatings & Surface Treatments

Can you re-tap hex nuts after galvanising?

Yes. Hot-dip galvanising often clogs or distorts internal threads due to the zinc coating thickness (typically 85+ microns). Our retapping service restores threads to specification after coating. We can retap your existing nuts or manufacture new nuts and retap post-galvanising as part of the service. The retapping process removes excess zinc from the thread form whilst leaving the external coating intact for corrosion protection. This is common practice in structural steel, outdoor infrastructure, and electrical transmission applications where both galvanic protection and precise thread fit are required. We can retap to standard size or to oversize if specified.

What surface finishes are available for hex nuts?

We offer a comprehensive range of surface finishes including zinc plating (clear, yellow, black), hot-dip galvanising, passivation (for stainless steel), anodising (for aluminium), and various specialist coatings. Each finish offers different levels of corrosion protection, temperature resistance, and aesthetic appearance. For detailed finish specifications, performance characteristics, and recommendations, please visit our dedicated Surface Finishes page or contact us to discuss your specific requirements.

Standards & Specifications

What is the difference between ISO 4032 and DIN 934?

ISO 4032 superseded DIN 934 as the international standard for metric hex nuts. The dimensional specifications are nearly identical, with minor tolerance differences in across-flats and thickness for some sizes. DIN 934 is still widely referenced in existing engineering drawings and remains compatible with ISO 4032 nuts in almost all cases. ISO 4032 specifies Style 1 nuts (product grades A and B) with chamfered ends, whilst DIN 934 covered a broader range of grades. For practical purposes, nuts manufactured to either standard are interchangeable in most applications.

In the UK, BS EN ISO 4032 is the current standard, which is the British adoption of the European harmonised ISO standard. We manufacture to BS EN ISO 4032, ISO 4032, DIN 934, or any equivalent specification and can provide certification indicating compliance. Additionally, we often manufacture to BS 3692 which is still current as of 2014. Generally, the tolerances are tighter for BS 3692 specification.

What are heavy hex nuts used for?

Heavy hex nuts have larger across-flats dimensions and greater thickness than standard nuts. They provide increased thread engagement, higher load capacity, and reduced nut expansion under torque. Used in structural steel construction, heavy machinery, and applications requiring high clamping forces to BS 1769 (Unified heavy hex), BS EN 14399-4 (metric structural), DIN 6915 (metric), or customer specifications. The increased material thickness engages more threads, distributing load over a larger area and reducing stress concentrations. The larger across-flats dimension provides more leverage for tightening and increases the nut's resistance to expansion under high torque. Heavy hex nuts are essential in:

- Structural steel frameworks (buildings, bridges, towers)

- Preloaded bolt assemblies to BS EN 14399 (structural bolting)

- Heavy machinery foundations

- Crane and lifting equipment

- Wind turbine tower flange connections

- Pressure vessel flanges

Heavy hex nuts typically require larger sockets or spanners than standard nuts of the same thread size.

Can you manufacture to obsolete or withdrawn standards?

Yes. We specialise in manufacturing nuts to obsolete, superseded, and withdrawn standards for heritage restoration, vintage machinery repair, and replacement parts. This includes:

- BS 1083:1965 (Whitworth/BSF hex nuts) - withdrawn but still needed for classic vehicles

- BS 916 (black hex nuts) - superseded by BS 4190

- BS 949 (bright hex nuts) - withdrawn

- AN series (aircraft nuts) - military specs superseded by NAS

- Obsolete DIN standards replaced by ISO equivalents

- Withdrawn military specifications (MIL-N, MS, NAS)

We maintain an extensive library of historical fastener standards and can manufacture from technical drawings, samples, or published specifications. Many restoration projects, museum exhibits, heritage railways, and classic vehicle enthusiasts require exact replacements to maintain authenticity. If you have a sample nut or a standard reference, we can reverse-engineer and manufacture to the original specification.

What does "Grade A" and "Grade B" mean for hex nuts?

In ISO standards (ISO 4032, 4033, etc.), Grade A and Grade B refer to tolerance grades—how precisely the nut dimensions must conform to nominal values:

- Grade A: Fine tolerance, typically ±0.02-0.04mm on across-flats for smaller sizes. Used in precision engineering, aerospace, and applications where close dimensional control is critical.

- Grade B: Medium tolerance, typically ±0.04-0.08mm on across-flats. Suitable for general engineering applications where slight dimensional variation is acceptable.

Grade A nuts cost more to manufacture due to tighter quality control and inspection requirements. For most industrial applications, Grade B provides adequate precision. Aerospace, automotive safety components, and precision machinery typically specify Grade A. We can manufacture to either grade depending on your requirements and can provide dimensional inspection reports confirming conformance.

What is BS EN 14399 and when is it required?

BS EN 14399 is the British adoption of the European standard for structural bolting assemblies used in high-strength preloaded applications, primarily in structural steelwork (buildings, bridges, masts, towers). It specifies combined sets of bolts, nuts, and washers that are designed to work together to achieve specific preload requirements. Parts manufactured to BS EN 14399 must be traceable, heat-treated to precise specifications, and often supplied with test certificates.

The nuts (BS EN 14399-4) are typically heavy hex pattern with specific across-flats dimensions and hardness requirements. BS EN 14399 assemblies are mandatory for structural steel connections in construction projects across the UK and EU. This standard superseded older British standards for structural bolting and is the current requirement for all major construction and infrastructure projects.

We can manufacture hex nuts to BS EN 14399-4 with full material traceability and certification for structural applications. These nuts must be supplied with 3.1 certificates to EN 10204 and are typically marked with manufacturer identification and grade markings.

Do you manufacture nuts to American ASTM specifications?

Yes. Whilst we primarily work to British (BS, BS EN, BS EN ISO) and European (DIN, DIN EN) standards, we can manufacture hex nuts with mechanical properties conforming to American ASTM specifications for export or international projects:

- ASTM A563 (carbon and alloy steel nuts) - Grades A, B, C, DH, DH3

- ASTM A194 (carbon and alloy steel nuts for high-pressure/high-temperature service) - Grades 2H, 4, 7, 8, 8M

- ASTM F594 (stainless steel nuts)

- ASME B18.2.2 (dimensional standards for hex nuts)

ASTM A563 grades specify minimum proof loads, hardness requirements, and testing procedures. Grade DH (heavy hex) nuts must withstand higher proof loads than Grade A nuts. ASTM A194 covers nuts for flanged connections in pressure piping, boilers, and pressure vessels. We can provide material test reports (MTRs) certified to ASTM specifications, essential for petrochemical, power generation, and North American export applications. For UK domestic applications, we recommend using BS EN or BS EN ISO equivalent specifications where available.

Manufacturing Process & Capabilities

How are hex nuts manufactured at Trojan?

We chiefly use cam-operated automatic lathe machines and CNC bar turning (precision lathe machining) to manufacture hex nuts from solid hexagon, round and square bar stock. The process involves:

- *Material selection*: Hexagon bar in the specified material (steel, stainless, brass, aluminium, etc.) is loaded into the CNC lathe.

- *Facing and centring*: The end face is machined flat and square, and the centre is drilled for thread tapping.

- *Drilling*: A pilot hole is drilled to the core diameter required for the internal thread.

- *Thread tapping*: The internal thread is cut using precision taps (single-point threading for special threads).

- *Chamfering*: One or both ends are chamfered at 30° as per specification. Single-chamfered nuts have one face left flat (bearing face).

- *Parting off*: The nut is cut from the bar stock to the specified thickness.

- *Secondary operations* (if required): Cross-drilling for split pins, slotting for castle nuts, knurling, deburring.

- *Quality inspection*: Dimensional verification, thread gauging, visual inspection.

- *Surface finishing* (if specified): Sent for plating, galvanising, anodising, or other coating.

- *Final inspection and packing*: Certified and packaged per customer requirements.

This bar-turning method ensures excellent concentricity between hex body and thread, consistent across-flats dimensions, and precise thread quality. We can machine from single prototypes to batches of thousands.

Do you manufacture left-hand thread hex nuts?

Yes, we manufacture left-hand threads in metric, Imperial, and Unified forms across our full size range. Left-hand nuts are often used to prevent self-loosening on rotating shafts or for mechanical advantage in turnbuckles. Common applications include:

- Right-hand rotating shafts where standard right-hand threads would unscrew under rotation (left pedals on bicycles, left-side wheel studs on some vehicles)

- Turnbuckles and adjustable struts (one end left-hand, one end right-hand for mechanical advantage)

- Machinery with contra-rotating components

- Safety-critical applications where opposite-hand threads prevent accidental disassembly

Left-hand threads are typically marked with grooves, notches, or "L" rolled on a flat or "LH" stamping to prevent installation errors. We can machine left-hand threads in most sizes from M3 to M56 metric, 2BA to 2" Imperial, and #8 to 2.1/4" Unified.

Can you supply oversize hex nuts?

Yes. Oversize hex nuts have threads larger than the nominal diameter—used for retapping worn or damaged female threads, or for specific engineering tolerances. Common oversize increments: +0.015", +0.030". Oversize nuts are frequently needed for:

- Repairing stripped or damaged threads in castings, aluminium components, or soft materials

- Compensating for manufacturing tolerances in mass-produced parts

- Retapping galvanised or coated threads that have expanded

- Field repairs where rethreading the bolt is not feasible

For example, an M16+0.015 oversize nut would have an internal thread of approximately 16.015mm major diameter instead of the standard 16mm. We can manufacture oversize nuts to your specified increment in any thread form. The external across-flats dimension remains standard unless otherwise specified.

What's the minimum order quantity for custom hex nuts?

We have no minimum order quantity. We manufacture single prototype nuts through to batch production in the thousands. Our CNC bar-turning process is economical for small quantities because setup times are minimal and there's no requirement for expensive forging dies or high-volume tooling. Many customers order:

- 1-5 units for prototypes, R&D, or testing

- 10-50 units for low-volume assembly or field repairs

- 100-500 units for small production runs

- 1,000+ units for series production or inventory stocking

Pricing obviously improves with quantity due to economies of scale, but we're happy to quote and manufacture single nuts for urgent repairs or one-off applications. This flexibility is one of our key differentiators—most manufacturers require minimum batches of hundreds or thousands.

Can you machine hex nuts from round bar instead of hexagon bar?

Yes. We offer polygon turning services to machine hexagon or square profiles from round bar. This is particularly useful because:

- Hexagon or Square bar is increasingly difficult to source in most materials

- Hexagon or Square bar may not be available in the specific across-flats dimension you need

- You have free-issue round bar stock you want us to use

- Smaller quantities where purchasing hexagon bar isn't economical

Our polygon turning capability allows us to machine precise four-sided square and six-sided hex flats from round bar stock. The process adds some machining time compared to starting with hex bar, but ensures availability and eliminates material sourcing delays. We can also turn square nuts (four sides) from round bar using the same technique.

Can you make hex nuts from customer free-issue material?

Yes. If you have specific material stock, we can machine nuts from your supplied bar. Minimum bar diameter and condition requirements apply. This service is common for:

- Aerospace applications requiring specific material certifications or batch traceability

- Medical devices where material biocompatibility certification is essential

- Nuclear industry with qualified material pedigrees

- Customers who have purchased material in bulk at favourable pricing

Your material must be supplied as bar stock (hexagon, square, or round) in good condition without excessive surface defects. We'll confirm bar diameter/AF requirements before you send material. Free-issue machining typically reduces overall part cost as you're only paying for our labour and tooling rather than material markup.

Quality, Certification & Inspection

Can hex nuts be supplied with material certificates?

Yes. We provide mill certificates, material test certificates (3.1 or 3.2 to EN 10204), and full traceability documentation upon request. Essential for aerospace, nuclear, oil & gas, and safety-critical applications. Certificate options include:

- EN 10204 2.1: Declaration of compliance from the manufacturer (basic)

- EN 10204 2.2: Test report from the manufacturer (our own test results)

- EN 10204 3.1: Inspection certificate with third-party verification

- EN 10204 3.2: Inspection certificate with independent inspection by an authorised body

Certificates typically include: material grade, heat/batch number, chemical composition analysis, mechanical properties (tensile strength, yield strength, hardness), manufacturing standard compliance, and full traceability back to the steel mill. This documentation is mandatory for regulated industries and allows you to maintain supply chain traceability for quality assurance and liability purposes. All we ask is that you ask about certification at the quotation stage so that we can confirm that our suppliers can provide us the relevant documentation.

What inspection and quality control do you perform?

All hex nuts manufactured at Trojan undergo quality control procedures in accordance with ISO 9001:2015:

*First Article Inspection: First part from each batch is dimensionally verified against drawing or standard

Thread gauging: GO and NO-GO thread gauges confirm thread accuracy

Dimensional verification: Across-flats, thickness, chamfer angles measured with callipers, micrometers, or CMM

Visual inspection: Surface finish, machining quality, absence of defects

Hardness testing (when specified): Rockwell or Vickers hardness testing

Material verification (when certified): XRF analysis to confirm material grade

Proof Load Testing* (when specified): external labs perform the tests for us.

We can provide:

- First Article Inspection Reports (FAIR) to AS9102

- Dimensional inspection reports

- Thread gauge inspection records

- Certificates of Conformity (CoC)

- Material test certificates

- Photographic evidence of finished parts

For high-value or safety-critical applications, we offer 100% inspection where every single nut is individually verified.

How do you ensure threads are accurate?

Thread accuracy is critical for proper fastener function. We ensure precision threads through:

1. *Precision tooling: High-quality taps from reputable manufacturers (Dormer, Gühring, OSG) with regular replacement schedules

2. Controlled feeds and speeds: CNC programming optimised for each material to prevent oversize or undersize threads

3. Thread gauge verification: Every batch is verified with GO and NO-GO thread gauges to confirm thread limits conform to tolerance class (6H metric, 2B Unified, etc.)

4. Coolant and lubrication: Appropriate cutting fluids prevent heat distortion and ensure clean thread forms

5. Tool wear monitoring: Regular tool inspection and replacement before wear affects thread quality

6. Single-point threading* (for special threads): When taps aren't available, we single-point thread on the CNC lathe for complete control over thread geometry

For critical applications, we can provide thread gauge inspection reports and certification that threads conform to ISO 965, ASME B1.1, or other applicable standards.

Sizing, Selection & Technical Questions

How do I know what size hex nut I need?

To select the correct hex nut, you need:

1. *Thread size and pitch*: This must match your bolt or stud exactly. For metric: M8, M10×1.25, etc. For Unified: 1/4"-20 UNC, 1/2"-13 UNC. For Imperial: 3/8" BSW, 1/2" BSF, etc.

2. *Thread form*: Metric (ISO), Unified (UNC/UNF), Imperial (BSW/BSF/BA), or special

3. *Nut height/thickness*: Standard (full nut), thin (lock nut, jam nut), or heavy (heavy hex). Standard nuts are approximately 0.8d to 1.0d thick where d = nominal diameter.

4. *Across-flats (AF)*: Usually standard for the thread size, but can be custom. This determines what spanner fits.

5. *Material and finish*: Based on application environment and strength requirements

6. *Single or double chamfer*: BSW/BSF often single-chamfered; metric usually double-chamfered

If you have an existing bolt and need a matching nut, the easiest method is to send us a sample or provide the thread specification from the bolt markings. We can also help you measure and identify unmarked threads.

What's the maximum size hex nut you can manufacture?

Our largest regular capacity is M56 metric and 2.1/4" Unified. For larger sizes, we can quote special production. Custom across-flats dimensions available to suit any spanner size requirement. Very large nuts (above M56/2.25") are typically machined from solid blanks rather than bar stock, or may require alternative manufacturing methods. If you need nuts larger than our standard capacity, contact us with your specification—we'll advise if we can manufacture them in-house or arrange production through our supply chain partners.

Can you make panel nuts with fine threads?

Yes. Panel nuts typically have fine-pitch threads (e.g., 32 TPI Unified, M8×0.5 metric) and thin profiles (0.08"-0.125"). We manufacture panel nuts for electrical/electronic enclosures, often with reduced AF dimensions for high component density. Panel nuts are common in:

- Electronics enclosures (potentiometer mounting, connector housings)

- Control panels and switchgear

- Instrumentation bezels

- Audio/video equipment

- Telecommunications equipment

Fine pitches (28, 32, 36 TPI in Unified; 0.5mm, 0.75mm in metric) allow secure fastening with minimal thread engagement in thin panel materials. The reduced across-flats (often undersized compared to standard nuts of the same thread) allow close spacing of multiple components on densely packed panels. We can manufacture panel nuts in brass, aluminium, stainless steel, or nylon depending on electrical conductivity requirements.

Do you manufacture nylon hex nuts?

Yes. We machine hex nuts from Nylon 6, Nylon 66, Acetal (Delrin), PEEK, and other engineering plastics. Ideal for electrical insulation, lightweight assemblies, and non-metallic corrosion-free applications. Plastic nuts offer advantages:

- Electrical insulation (no conductive path)

- Chemical resistance (acids, alkalis, solvents)

- Non-magnetic (MRI equipment, electronics)

- Lightweight (aerospace, drones, radio-controlled models)

- Low friction (self-lubricating in some grades)

- Corrosion-free (marine, outdoor, chemical environments)

- Vibration damping (reduced noise in mechanical assemblies)

Limitations of plastic nuts include lower strength (don't over-torque), temperature limits (typically max 80-120°C for nylon, up to 260°C for PEEK), and UV degradation (unless stabilised grades are used). We typically recommend plastic nuts for low-to-moderate torque applications where their unique properties outweigh the strength limitations. Common in electronics, medical devices, food processing equipment, and outdoor furniture.

What's the difference between a jam nut and a lock nut?

The terms are often used interchangeably, but technically:

*Jam nut* (also called lock nut or half nut): A thin hex nut, typically 0.45d thick, used in pairs to lock another nut in position or to provide a low-profile fastening. When two jam nuts are tightened against each other on the same bolt, they create prevailing torque that resists loosening. The name "jam nut" comes from "jamming" two nuts together. Common uses include locking adjustable components in position, low-profile applications where full-height nuts are too tall, and secondary locking for critical fastenings.

To avoid confusion, we recommend specifying "thin hex nut" or "jam nut" for reduced-height nuts, or "lock nut" with specific type (nylon insert, distorted thread, etc.) if a self-locking feature is needed beyond this hex nut page.

What are heavy hex nuts and when should they be used?

Heavy hex nuts have both larger across-flats (AF) dimensions and greater overall thickness compared to standard hex nuts of the same thread size. For example, a standard M20 hex nut to BS EN ISO 4032 has 30mm AF and 18mm thickness, whilst a heavy hex M20 to BS EN 14399-4 would have 34mm AF and 20mm thickness (exact dimensions depend on the standard). For Unified threads, BS 1769 specifies heavy hex nuts with increased dimensions compared to standard BS 1768 nuts. The benefits include:

- Increased thread engagement: More thread turns engaged = higher pull-out resistance and load capacity

- Reduced nut expansion: The thicker walls prevent the nut from expanding radially under high torque

- Larger bearing surface: Greater contact area distributes clamping force more effectively

- Higher proof loads: Can withstand greater tensile forces before failure

- Better suited to high-strength bolts: Grade 8.8, 10.9, and 12.9 bolts require nuts that won't fail before the bolt does

Heavy hex nuts are essential for:

- Structural steel bolting to BS EN 14399 (metric) or BS 1769 (Unified)

- Bridge construction and tower assemblies

- Pre-loaded high-strength bolt connections

- Heavy machinery and equipment mounting

- Pressure vessel flanges

- Wind turbine tower connections

The larger AF dimension requires correspondingly larger sockets or spanners—a heavy hex M20 to BS EN 14399-4 requires a 34mm socket instead of the standard 30mm.

What are double-thick hex nuts?

Double-thick hex nuts (also called extended nuts or deep nuts) have approximately 1.5× to 2.0× the thickness of standard full nuts. For example, where a standard M16 full nut might be 13mm thick, a double-thick M16 could be 20-26mm thick. The benefits include:

- Maximum thread engagement: The extended height engages significantly more thread turns, dramatically increasing pull-out strength

- Load distribution: Stress is distributed over more threads, reducing stress concentration on any single thread

- Long bolt guidance: The extended nut height helps guide and stabilise long bolts during assembly

- Thick material fastening: When joining very thick plates, beams, or multiple layers, standard nuts may not provide adequate thread engagement

Applications include:

- Heavy timber construction (thick beams, engineered wood connections)

- Structural connections requiring maximum strength

- Equipment mounting through thick base plates

- Applications where the bolt thread doesn't extend far through the joint

- Situations where additional thread engagement is specified by design engineers

Double-thick nuts are particularly valuable when using high-strength bolts where maximising the thread engagement prevents the nut threads from stripping before the bolt reaches its ultimate tensile strength.

What is a washer-faced hex nut and why would I use one?

A washer-faced hex nut has one face machined with a flat, raised circular bearing surface (washer face) that extends beyond the chamfered edges. This integral washer increases the bearing area significantly compared to a standard chamfered face. Benefits include:

- Increased bearing area: Distributes clamping loads over a larger surface area

- Prevents substrate damage: Ideal for soft materials (aluminium, plastics, timber, thin sheet metal) where a standard nut might pull through or cause indentation

- Eliminates separate washer: Reduces assembly time and parts count

- Better load distribution: Creates more even pressure across the joint surface

- Improved friction: Larger flat surface increases resistance to loosening

Typical applications:

- Mounting equipment to thin sheet metal panels

- Fastening to timber, plywood, or composite materials

- Aluminium structures where bearing stress must be minimised

- Applications where eliminating separate washers simplifies assembly

- Situations requiring high clamping force on relatively soft substrates

The washer face diameter is typically 1.5× to 2.0× the nut's across-flats dimension. Washer-faced nuts are non-reversible—the washer face must always contact the joint surface.

Can I use a standard hex nut with a heavy hex bolt, or vice versa?

While they will physically thread together (assuming same thread size and form), it's not recommended for demanding applications. Heavy hex bolts are designed for use with heavy hex nuts because:

- The bolt head and nut across-flats dimensions are matched for consistent spanners/sockets

- Heavy hex bolts often indicate high-strength applications (Grade 8.8, 10.9, or higher) requiring heavy hex nuts with greater thickness to prevent thread stripping

- Structural applications to BS EN 14399, BS 1769, or similar specifications specifically require matched heavy hex bolt-and-nut assemblies

- Using a standard nut on a heavy hex bolt may result in nut failure before the bolt reaches its proof load

For general, non-critical applications, a standard nut on a heavy hex bolt may be acceptable, but always verify that the nut's proof load exceeds the design loads. For structural or safety-critical applications, always use matched components as specified in BS EN 14399-4 or BS 1769.

Why do hex nuts have chamfered edges?

The 30° chamfer on hex nut faces serves several important functions:

- Ease of starting: The angled edge allows the nut to be easily guided onto the bolt thread without cross-threading

- Deburring: The chamfer removes sharp edges from the machining process, preventing cuts during handling

- Clearance: In countersunk or recessed applications, the chamfer provides clearance

- Stress relief: The angled edge reduces stress concentrations at sharp corners

- Visual/functional distinction: On single-chamfered nuts, the unchamfered face clearly identifies the bearing surface

The chamfer diameter is typically approximately 90% of the minimum across-flats dimension, ensuring the chamfer doesn't reduce the effective bearing area excessively whilst still providing these functional benefits.

Ordering, Pricing & Lead Times

How quickly can you manufacture custom hex nuts?

Lead times vary by complexity, material availability, and quantity:

- *Standard materials, straightforward specs: 3-5 working days

- Exotic materials (titanium, Inconel, special alloys): 2-4 weeks (material procurement + machining)

- Large quantities (1,000+ units): 2-4 weeks depending on batch size

- Urgent orders*: Contact us—we can often accommodate rush production

Factors affecting lead time include:

- Material availability (stock materials ship faster)

- Threading complexity (special pitches take longer than standard)

- Secondary operations (coating, heat treatment, special finishing)

- Inspection requirements (full inspection reports add time)

- Current production schedule loading

For urgent requirements, call us on 0121 789 8586 to discuss expedited production. We understand breakdowns and urgent repairs happen—we'll do everything possible to help.

What information do you need for an accurate quotation?

To provide an accurate quotation, please supply:

1. *Thread specification: Size, pitch, form (e.g., M16×2.0, 1/2"-13 UNC, 3/8" BSF)

2. Across-flats (AF) dimension: Standard or custom size

3. Nut thickness/height: Standard, thin, thick, or dimensioned

4. Material: Steel grade, stainless type, brass, aluminium, plastic, etc.

5. Surface finish: Bright, zinc-plated, galvanised, self-colour, anodised, etc.

6. Single or double chamfer (or washer-faced, if applicable)

7. Quantity required: Affects unit pricing

8. Any special features: Left-hand thread, oversize, cross-drilling, slots, etc.

9. Quality/inspection requirements: Certificates, inspection reports, material traceability

10. Delivery timescale: Standard or urgent

11. Drawing or sample* (if available): Eliminates ambiguity

The more information you provide, the faster and more accurate our quotation. If you're unsure about any specifications, just send us what you have—we'll help work out the details.

Why do prices vary for the same size nut?

Hex nut pricing depends on multiple factors beyond just the thread size:

- *Material cost: Stainless steel costs 3-5× more than mild steel; titanium costs 10-20× more

- Material availability: Exotic materials or unusual hexagon bar sizes may have minimum order quantities from suppliers

- Machining time: Fine threads, hard materials, and tight tolerances require slower cutting speeds

- Thread complexity: Special pitches, left-hand threads, oversize threads require custom tooling

- Quantity: Unit price drops significantly with higher volumes (economies of scale)

- Surface finishing: Plating, galvanising, anodising, coating adds cost

- Inspection/certification: Material certificates, dimensional reports, traceability documentation

- Special features: Cross-drilling, slotting, knurling, secondary operations

- Lead time*: Rush production may incur expedite charges

For example, a simple M10×1.5 full nut in EN1A bright finish might cost £0.50 each in quantities of 100. The same M10 in 316 stainless with zinc-flake coating and material certificate could cost £5.00+ each. Always specify all requirements for accurate pricing.

Do you offer discounts for larger quantities?

Yes. Unit pricing decreases with quantity due to:

- Setup time amortised over more parts

- Bulk material purchasing (better pricing from suppliers)

- Production efficiency (longer uninterrupted runs)

- Reduced per-unit handling and packaging costs

Typical pricing breaks occur at quantities of 50, 100, 250, 500, 1,000, and 5,000 units. For very large ongoing requirements, we can quote annual supply agreements with volume commitment discounts. If you have a regular requirement for specific nuts, purchasing in larger batches and stocking them will usually save money in the long run. We can also hold inventory for you under call-off arrangements if storage is an issue.

Installation, Torque & Troubleshooting

What torque should I apply to hex nuts?

Correct torque depends on:

- Thread size and pitch

- Material strength (bolt and nut)

- Lubrication condition (dry, oiled, anti-seize)

- Application requirements (proof load, clamping force needed)

- Prevailing torque (if lock nuts are used)

As a rough guide for dry steel fasteners (no lubrication):

- M8: 20-25 Nm

- M10: 40-50 Nm

- M12: 70-85 Nm

- M16: 160-200 Nm

- M20: 300-380 Nm

*However*, these are indicative only. Lubrication can reduce required torque by 20-30%. High-strength bolts require different torques than standard grades. For critical applications, consult:

- Bolt manufacturer's torque specifications

- Engineering standards (VDI 2230, ISO 898)

- Assembly procedure specifications

- Torque-tension test data for your specific combination

Over-torquing can strip threads, stretch bolts beyond yield, or crack nuts. Under-torquing results in insufficient clamping force and potential loosening. Use calibrated torque wrenches and follow proper tightening sequences for multi-bolt joints.

Why do hex nut threads sometimes gall or seize?

Galling (cold welding) occurs when mating metal surfaces adhere under pressure and sliding friction, particularly with stainless steel threads. Prevention methods:

- Lubrication: Apply anti-seize compound, thread lubricant, or molybdenum disulphide to threads before assembly

- Slow installation: Don't run nuts down quickly—heat buildup promotes galling

- Material selection: Avoid stainless-on-stainless combinations; use bronze or brass nuts with stainless bolts

- Surface treatment: PTFE coating, silver plating, or nitriding reduces friction

- Thread class: Looser thread fits (class 3B instead of 2B) reduce contact pressure

- Clean threads: Remove dirt, burrs, and contamination before assembly

If threads do seize:

- Apply penetrating oil and wait 24 hours

- Alternate tightening/loosening to break the bond

- Apply heat (if materials permit) to expand and break the weld

- As last resort: cut the nut off with an angle grinder or nut splitter

For applications prone to galling (stainless fasteners, high-torque assemblies, outdoor exposure), always use thread lubricant and consider anti-galling coatings.

Can damaged or stripped hex nut threads be repaired?

Internal threads in nuts cannot be repaired once stripped—the nut must be replaced. However, you can prevent future stripping:

- Use oversize nuts (+0.25mm, +0.5mm) to re-tap worn holes

- Specify higher-strength materials (EN24 instead of EN1A)

- Use heavy hex nuts for higher thread engagement

- Install helicoil thread inserts in the component the nut threads onto

- Don't over-torque—use calibrated torque wrenches

- Ensure bolt and nut materials are compatible (similar hardness)

If you've stripped threads in a tapped hole (casting, housing, frame), that can be repaired with helicoils or thread inserts. But once a nut's internal threads are damaged, replacement is the only solution. We can manufacture replacement nuts to the original specification or suggest upgraded materials/designs to prevent recurrence.

How do I remove a rounded (damaged) hex nut?

A hex nut with rounded corners (flats damaged from incorrect spanner size or over-torque) is difficult to remove. Methods include:

1. Vise grips (mole grips): Clamp tightly on the remaining flats and turn carefully

2. Nut splitter: Chisel-type tool that cuts a slot through one flat, allowing the nut to be spread and removed

3. Weld a new nut: Weld a sacrificial nut on top of the rounded nut, then turn using the new nut

4. File new flats: Carefully file two opposite faces to create parallel flats for a smaller spanner

5. Hammer and chisel: Tap the nut in the loosening direction (risk of damage to threads)

6. Cut with angle grinder: Last resort—cut a slot through the nut or cut the nut in half

7. Drill out: Drill progressively larger holes until the nut breaks (risk of damaging bolt threads)

Prevention is better than cure:

- Always use the correct spanner size

- Keep spanners and sockets in good condition

- Don't use adjustable spanners on stubborn nuts

- Apply penetrating oil to seized nuts before attempting removal

- Use six-point sockets rather than twelve-point (better corner engagement)