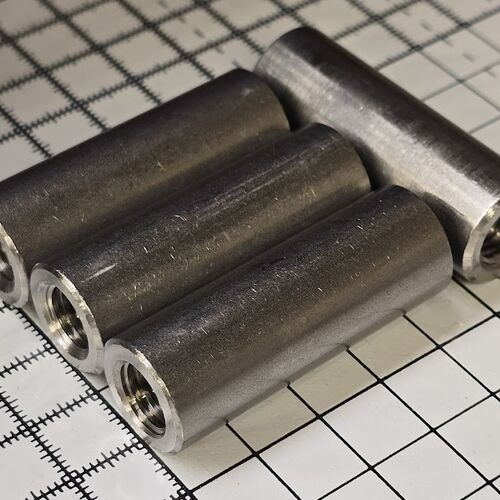

Round Nuts and Spacers

Trojan Special Fasteners Ltd routinely manufactures round nuts to customer’s requirements in multiple material and finish combinations.

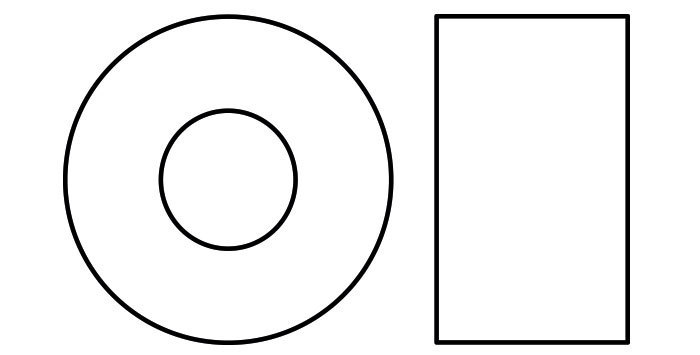

Unchamfered

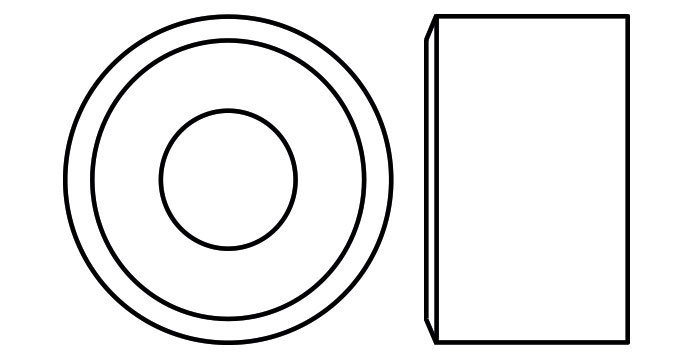

Single Chamfered

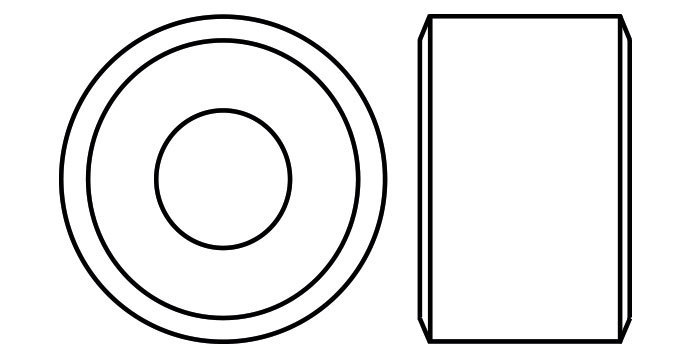

Double Chamfered

We manufacture a number of round nuts, which are not tightened by a wrench, but by hand. These are quite uncommon but we can make almost any combination of internal and external diameter you’re looking for within available material specifications and finishes.

Trojan special fasteners can build additional features into fasteners, like collars, castellated, slotted portions and also cross drill and tap these.

We can machine round nuts to your dimensions, drawing or sample in a multitude of sizes, materials and finishes.

In addition to standard preferred sizes, we also manufacture non preferred and non standard or special thread and nut forms and sizes.

Precision Bar-Turned Round Nuts | Cylindrical Nuts | Boss Nuts | Knurled Nuts

Trojan Special Fasteners Ltd manufactures precision round nuts (also known as cylindrical nuts, boss nuts, round bosses, thumb nuts, and bearing nuts) to exacting specifications for engineering, electrical, furniture, instrumentation, and industrial applications throughout the UK and internationally. As a specialist bespoke round nut manufacturer based in Birmingham, we produce round nuts from M3 to M52 in metric, 2BA to 2" in Imperial (BSW/BSF), and #8 to 2.1/4" in Unified (UNF/UNC) thread forms. Our CNC bar-turning capabilities ensure exceptional accuracy, consistency, and finish for both standard and non-standard specifications.

What Are Round Nuts?

Round nuts are internally threaded fasteners with a smooth cylindrical outer profile, designed primarily for hand-tightening applications where wrench access is limited, aesthetics matter, or frequent assembly/disassembly is required. Unlike hexagon or square nuts that require spanners or sockets, round nuts are typically tightened using finger pressure, screwdrivers (for slotted versions), hook spanners (for bearing nuts), or through knurled gripping surfaces (for thumb nuts).

The cylindrical shape offers several advantages: smooth aesthetics without protruding corners, ability to fit through round holes or recesses, protection from accidental loosening by hand, suitability for applications requiring free rotation until final tightening, and minimal risk of snagging on adjacent components or materials.

Round nuts are manufactured by CNC bar turning from solid round bar stock, ensuring concentricity, surface finish quality, and dimensional precision. We produce round nuts in diameters from small instrument sizes to large industrial applications, with custom features including slots, holes, knurling, flanges, collars, and mixed or left-hand threads.

Types of Round Nuts We Manufacture

Plain Round Nuts (Smooth Cylindrical)

Basic round nuts with smooth external surfaces, typically tightened by hand or with specialised pin spanners inserted through holes. Used in furniture assembly, instrument panels, electrical enclosures, and anywhere finger-tightening is sufficient and wrench access is impractical.

Slotted Round Nuts (DIN 546)

Round nuts with a single diametral slot cut across the top face, allowing tightening with a flat-blade screwdriver. DIN 546 specifies dimensions for slotted round nuts from M1.4 to M20, commonly used in electrical engineering, machine construction, and low-stress applications. The slot provides positive torque application whilst maintaining the round aesthetic.

Round Nuts with Face Holes (DIN 547)

Cylindrical nuts with one or more holes drilled on the top face, used with pin spanners or tommy bars for tightening. DIN 547 covers sizes typically from M4 to M30. The holes allow greater torque application than plain round nuts whilst preventing accidental loosening.

Round Nuts with Side Holes (DIN 548)

Round nuts featuring holes drilled through the cylindrical side wall, perpendicular to the thread axis. DIN 548 specifies these nuts from M4 to M36. Side holes accommodate pins, wire locking, or C-spanners, useful where top access is restricted.

Knurled Nuts and Thumb Nuts

Round nuts with textured knurled surfaces (straight, diagonal, or diamond pattern) on the outer cylindrical wall, designed for tool-free hand tightening. Common standards include DIN 6303 (knurled nuts), DIN 467 (flat knurled nuts), and DIN 466 (high knurled nuts). The knurled pattern provides excellent grip, making these ideal for applications requiring frequent adjustment—instrument panels, furniture, camera equipment, electronics enclosures, and machinery guards.

Bearing Lock Nuts (Hook Spanner Nuts)

Specialised round nuts with multiple external radial slots around the face, tightened using hook spanners. Used extensively for securing bearings onto shafts, mounting bearings on tapered seats, and locking components in precision machinery. The external slots distribute torque evenly and prevent nut deformation during installation.

Boss Nuts (Round Bosses)

Short cylindrical nuts, often with flanges or collars, designed for welding or press-fitting into panels, sheet metal, or castings. Boss nuts provide strong threaded inserts in thin materials where tapping threads directly would be impractical.

Flanged and Collared Round Nuts

Round nuts with integral flanges or collars providing increased bearing surface area. The flange distributes clamping load, reduces surface pressure, and can eliminate the need for separate washers. We manufacture flanged round nuts with various flange diameters and thicknesses to customer specifications.

Round Connector Nuts (Cylindrical Coupling Nuts)

Elongated round nuts used to join two externally threaded components. These cylindrical coupling nuts are typically 2d to 3d in length (where d = nominal diameter) and can feature mixed threads, left-hand/right-hand combinations, or sight holes. Common in turnbuckle assemblies, instrumentation, and where hexagon profiles are undesirable.

Thread Sizes and Forms We Manufacture

Metric Threads (ISO Metric)

M3, M4, M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M20, M22, M24, M25, M26, M27, M28, M30, M32, M33, M34, M35, M36, M38, M39, M40, M42, M45, M48, M50, M52, M56

Available in coarse pitch (standard), fine pitch, extra fine pitch, and special hard-to-find pitches. Left-hand thread variants available across all sizes. Oversize thread diameters for specific applications.

Imperial British Threads (BSW/BSF/BA)

British Standard Whitworth (BSW), British Standard Fine (BSF), British Standard Brass, British Standard Cycle, British Association (BA): 2BA, 4BA, 6BA, 8BA, 10BA, 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2"

Unified Threads (UNC/UNF/UNEF)

Unified Coarse (UNC), Unified Fine (UNF), Unified Extra Fine (UNEF): #8, #10, 1/4", 3/16", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1.1/16", 1.1/8", 1.3/16", 1.1/4", 1.5/16", 1.3/8", 1.7/16", 1.1/2", 1.5/8", 1.3/4", 1.7/8", 2", 2.1/4"

Special and Obsolete Threads

British Standard Pipe (BSP), British Standard Conduit, Whitform, cycle threads, model engineering threads, and obsolete specifications for heritage restoration.

Materials and Finishes

We manufacture round nuts in extensive material and finish combinations:

Ferrous Materials

- Free-cutting steels: EN1A (230M07), EN1APb (230M07Pb) for excellent machinability

- Carbon steels: EN3B (080A15), EN8 (080M40), EN8D for higher strength applications

- Alloy steels: EN16T (605M36T), EN19T (709M40T), EN24T (817M40T) for demanding applications

- Stainless steels: 303 (free-cutting), 304 (A2), 316 (A4 marine grade), 431

- Case hardening steels: EN32, EN36 when surface hardness is critical

Non-Ferrous Materials

- Brass: CZ121 (CW614N) free-cutting brass, CZ122, CZ108 for corrosion resistance

- Copper: C101, C103 for electrical applications

- Aluminium: 6082-T6 (general engineering), 6061-T6 (aircraft-quality), 2014-T6 (aerospace), 7075-T6 (premium aerospace grade)

- Bronze: PB102 (phosphor bronze), CA104 (aluminium bronze), NES833 for naval/marine applications

- Nickel aluminium bronze for superior corrosion resistance in seawater

Surface Finishes

- Self-colour (as-machined)

- Zinc plating: Clear, yellow chromate (Cr3), black

- Zinc-nickel plating for enhanced corrosion protection

- Hot-dip galvanising (HDG) for large components

- Zinc flake coatings (Geomet, Dacromet) for extreme corrosion resistance without hydrogen embrittlement

- Electroless nickel plating

- Passivation for stainless steel

- Black oxide (blackening)

- Phosphate coatings

- Anodising for aluminium components

- Polishing (particularly for brass dome nuts and aesthetic applications)

Manufacturing Process

We manufacture round nuts using CNC bar turning from solid round bar stock:

Material Selection

Round bar in the specified material (steel, stainless, brass, aluminium, bronze) is loaded into the CNC lathe. Round bar is the natural starting material for round nuts, ensuring concentricity and eliminating the need for polygon turning.

Turning Operations

External diameter turning to final size with tight tolerances (typically ±0.05mm). Facing operations to achieve specified thickness. Chamfering or radiusing of edges as required.

Drilling and Tapping

Centre drilling followed by precision drilling to core diameter. Internal thread tapping using high-quality taps (ISO, DIN, BS standards). Thread gauging to ensure dimensional accuracy. Oversize tapping available when specified.

Secondary Operations

Slotting for DIN 546 type nuts using milling or slotting operations. Drilling of face or side holes (DIN 547/548) for pin spanner engagement. Knurling operations for thumb nuts—straight, diagonal, or diamond patterns. Cross-drilling and tapping for grub screws or locking features. Flange or collar machining for increased bearing area.

Quality Control

Thread gauge verification (go/no-go gauges). Dimensional inspection of external diameter, thickness, and hole positions. Visual inspection of finish and surface quality. Material traceability and certification when required.

British and International Standards

We manufacture round nuts to the following specifications:

DIN Standards (German Industrial Standards)

- DIN 546: Slotted round nuts (M1.4 to M20)

- DIN 547: Round nuts with drilled holes in one face (M4 to M30)

- DIN 548: Round nuts with set pin holes in side (M4 to M36)

- DIN 6303: Knurled nuts (M3 to M12)

- DIN 467: Flat knurled nuts (M3 to M16)

- DIN 466: High knurled nuts (M3 to M16)

BS Standards (British Standards)

- BS 1768: Slotted and castle nuts (includes round slotted configurations)

- BS 4320: Metal threads for use in marine environments (stainless and bronze round nuts)

ISO Standards

- ISO 4034: Hexagon nuts—Product grades A and B (property class references apply to round nut strength specifications)

- ISO 898-2: Mechanical properties of fasteners—Nuts with specified property classes (material grade requirements for round nuts)

Obsolete and Withdrawn Standards

- DIN standards superseded by ISO equivalents but still referenced in legacy drawings

- Historical British specifications for instrument and electrical applications

- Military specifications (Def Stan, MS, NAS) for aerospace round nuts

Applications and Industries

Electrical and Electronics

Round nuts are extensively used in electrical enclosures, switchgear, instrument panels, and control boxes where the smooth profile prevents snagging of wiring, provides a clean aesthetic, and allows mounting through round panel holes.

Furniture and Joinery

Furniture assembly utilises round nuts for adjustable feet, drawer runners, bed frame connections, and anywhere visible fasteners need to blend with the design. Knurled thumb nuts enable tool-free assembly and adjustment.

Instrumentation and Scientific Equipment

Precision instruments use small round nuts (BA threads, M3-M6 metric) for securing panels, bezels, and components where minimal profile and precise positioning are critical.

Bearing Mounting

Bearing lock nuts with hook spanner engagement secure rolling element bearings onto shafts, adjust bearing clearances, and provide precise axial location in machinery, gearboxes, and rotating equipment.

Automotive and Transport

Round nuts secure components in vehicle interiors, dashboards, and trim assemblies. Knurled nuts enable tool-free adjustment of mirrors, seats, and controls.

Marine and Defence

Bronze and stainless round nuts provide corrosion resistance in marine environments, securing instruments, hatches, and deck fittings where salt spray and immersion are concerns.

Heritage and Restoration

Classic vehicle, vintage machinery, and railway restoration often requires round nuts to original specifications, including obsolete BA threads and imperial sizes.

Medical and Laboratory Equipment

Cleanroom and laboratory instruments use stainless or brass round nuts where hygiene, corrosion resistance, and easy cleaning are paramount.

Custom Features and Special Nuts

We can incorporate numerous custom features into round nuts:

Flanges and Collars

Integral flanges increase bearing area, distribute loads, and eliminate separate washers. Collars provide shoulders for precise positioning or increased thread engagement length.

Cross-Drilling and Tapping

Radial holes tapped for grub screws to lock the nut onto shafts or threaded studs. Cross-drilling for wire locking or safety pins.

Mixed Threads

Round connector nuts can feature different thread sizes, pitches, or types on each end—for example, M12 × 1.75 one end, 1/2" UNF the other.

Left-Hand Threads

All round nut types available with left-hand threads for anti-loosening applications or turnbuckle assemblies.

Oversize Threads

Oversize thread diameters to accommodate worn or damaged mating threads, common in restoration work.

Slotted, Castellated, or Deformed Sections

Axial or radial slots for prevailing torque locking, castellation for cotter pin insertion, or thread deformation for all-metal locking.

Prevailing Torque Features

Nylon insert rings (for round thumb nuts requiring vibration resistance), mechanical thread deformation, or interference fit sections.

Quality Assurance and Certifications

ISO 9001:2015 Certification

Our quality management system ensures consistent product quality, traceability, and continuous improvement in all manufacturing processes.

Material Certification

We provide material test reports (MTRs), mill certificates, and EN 10204 3.1 certificates for materials when required, particularly for aerospace, defence, and critical applications.

Dimensional Inspection

All round nuts undergo dimensional verification including thread gauging (ISO 1502/BS 3643 go/no-go gauges), external diameter measurement, thickness verification, and hole position/size checking.

Traceability

Full batch traceability from raw material through manufacturing operations to final dispatch, essential for aerospace and medical applications.

Certificates of Conformity

We supply Certificates of Conformity confirming compliance with specified standards (DIN, BS, ISO), material grades, and finish requirements.

Frequently Asked Questions About Round Nuts

1. What are round nuts used for?

Round nuts are used in applications where hand-tightening is preferred, wrench access is limited, or aesthetics require a smooth cylindrical profile. Common uses include electrical enclosures, furniture assembly, instrument panels, bearing mounting, and any application requiring frequent disassembly where tool-free operation is beneficial.

2. How do you tighten a round nut without a wrench?

The method depends on the round nut type. Plain round nuts are hand-tightened using finger pressure. Slotted round nuts (DIN 546) use a flat-blade screwdriver. Round nuts with holes (DIN 547/548) use pin spanners or tommy bars. Knurled nuts and thumb nuts are tightened by gripping the textured surface. Bearing lock nuts require hook spanners that engage external slots.

3. Can you manufacture round nuts to custom dimensions?

Yes, we specialise in custom round nuts to your drawings, samples, or specifications. Custom features include non-standard diameters, thicknesses, thread forms, hole positions, knurling patterns, flanges, collars, and mixed threads. Minimum order quantities start from single prototype units.

4. What is the difference between DIN 546, DIN 547, and DIN 548 round nuts?

DIN 546 round nuts have a diametral slot on the top face for screwdriver tightening. DIN 547 nuts have one or more holes drilled on the top face for pin spanner engagement. DIN 548 nuts have holes drilled through the cylindrical side wall. Each design suits different access constraints and torque requirements.

5. Do you manufacture knurled nuts and thumb nuts?

Yes, we manufacture knurled nuts to DIN 6303, DIN 467, and DIN 466 standards, plus custom knurled configurations. Knurling patterns include straight, diagonal, and diamond knurl. Heights range from flat thumb nuts to high knurled nuts, all designed for tool-free hand operation.

6. What materials are available for round nuts?

We manufacture round nuts in carbon steels (EN1A, EN3B, EN8), stainless steels (303, 304, 316), brass (CZ121, CZ122), aluminium (6082-T6, 6061-T6, 2014-T6, 7075-T6), copper (C101), and bronzes (PB102, CA104, NES833). Material selection depends on strength, corrosion resistance, conductivity, and environmental requirements.

7. Can round nuts be supplied with surface finishes?

Yes, we provide zinc plating (clear, yellow, black), zinc-nickel, hot-dip galvanising, zinc flake coatings, electroless nickel, passivation (stainless steel), black oxide, phosphate, anodising (aluminium), and polishing. Finish selection depends on corrosion protection needs, appearance, and environmental conditions.

8. What thread sizes do you offer in round nuts?

We manufacture round nuts from M3 to M52 in metric, 2BA to 2" in Imperial (BSW/BSF/BA), and #8 to 2.1/4" in Unified (UNC/UNF/UNEF). Thread forms include coarse, fine, extra fine pitches, left-hand threads, and oversize. Special threads (BSP, BA, cycle) available for heritage and specialist applications.

9. Can you make round connector nuts with mixed threads?

Yes, round connector nuts (cylindrical coupling nuts) can feature different threads on each end—different sizes (e.g., M10 one end, M12 other end), different pitches (e.g., M12 × 1.75 and M12 × 1.25), different thread types (e.g., metric one end, Unified other end), or left-hand one end and right-hand the other (for turnbuckle applications).

10. What is the minimum order quantity for round nuts?

We manufacture from single prototype units to production quantities in the thousands. Our CNC bar-turning process is economical for small batches because setup times are minimal with no requirement for expensive forging dies or high-volume tooling.

11. Are round nuts suitable for high-stress applications?

Round nuts are generally intended for low-to-moderate stress applications because their smooth cylindrical profile limits torque application compared to hexagon or square nuts. However, round nuts with holes (DIN 547/548) or bearing lock nuts can handle higher torques when tightened with appropriate spanners. Material and thread size also determine stress capacity.

12. Do you manufacture round nuts with flanges?

Yes, we machine flanged round nuts with integral bearing flanges. The flange diameter, thickness, and angle can be customised. Flanged round nuts provide increased bearing surface area, distribute clamping loads, prevent embedding in soft materials, and eliminate the need for separate washers.

13. Can round nuts be made with internal collars or shoulders?

Yes, internal collars, shoulders, or steps can be machined into round nuts to provide precise spacing, limit thread engagement depth, or accommodate seals and O-rings. Specify collar dimensions and position on your drawing or enquiry.

14. What is a boss nut?

A boss nut (or round boss) is a short cylindrical nut, often with a flange or collar, designed for welding or press-fitting into sheet metal, panels, or castings. Boss nuts provide strong threaded inserts where the base material is too thin for reliable tapped threads.

15. Are bearing lock nuts the same as round nuts?

Bearing lock nuts are a specialised type of round nut featuring multiple external radial slots around the top face. They are tightened using hook spanners and are specifically designed for mounting bearings onto shafts or tapered seats, adjusting bearing clearances, and locking components in precision machinery.

16. Can you manufacture round nuts in BA thread sizes?

Yes, we manufacture round nuts in British Association (BA) thread sizes, commonly 2BA to 10BA. BA threads feature a 47.5° thread angle and are found in vintage electronics, telegraph equipment, scientific instruments, and clock mechanisms. Larger BA sizes available on request.

17. Do you supply round nuts for heritage and restoration projects?

Yes, we specialise in heritage fasteners including round nuts to obsolete specifications, imperial sizes, BA threads, BSW/BSF, and special pitches. Whether restoring classic vehicles, vintage machinery, railway equipment, or antique instruments, we can match original specifications or manufacture from samples.

18. Can round nuts be made with cross-drilled holes for grub screws?

Yes, we can cross-drill and tap round nuts for grub screws (set screws) to lock the nut onto a shaft or threaded component. Specify the grub screw thread size, number of holes, and position (radial or axial orientation).

19. What finish do you recommend for round nuts in marine environments?

For marine applications, we recommend material and finish combinations: stainless steel 316 (A4 marine grade) with passivation, bronze (PB102 phosphor bronze or CA104 aluminium bronze) self-colour, brass with nickel plating, or carbon steel with zinc-nickel or zinc flake coatings. Material selection often outweighs finish in truly harsh marine environments.

20. Can you machine knurling patterns to custom specifications?

Yes, we can produce straight knurl, diagonal knurl, diamond knurl, or custom knurling patterns to your specifications. Knurl pitch (TPI or module), depth, and pattern angle can be varied. Knurling may be applied to the full height or partial sections of the round nut.

21. What tolerances do you hold on round nut external diameters?

Typical external diameter tolerances for round nuts are ±0.05mm to ±0.1mm depending on size and application. Tighter tolerances (±0.02mm) are achievable for precision applications. Thread tolerances follow ISO 965 or BS 3643 (6H internal threads standard, 5H for finer tolerance).

22. Do you provide material test reports (MTRs) for round nuts?

Yes, we provide material test reports (MTRs), mill certificates, and EN 10204 3.1 certificates when specified. MTRs detail chemical composition, mechanical properties, and heat treatment records, essential for aerospace, defence, medical, and critical applications.

23. Can round nuts be supplied with nylon inserts for locking?

Yes, we can manufacture round thumb nuts with nylon inserts (typically Nylon 66) for prevailing torque locking. The nylon ring elastically deforms over the mating thread, creating friction that resists loosening from vibration. Suitable for applications up to approximately 120°C.

24. What is the difference between a knurled nut and a thumb nut?

The terms are often used interchangeably. Both feature textured knurled surfaces for hand-tightening without tools. "Thumb nut" emphasises the hand-operated nature, whilst "knurled nut" describes the surface treatment. Standards like DIN 6303/467/466 refer to "knurled nuts" regardless of height.

25. Can you manufacture round nuts in exotic materials like titanium or Inconel?

We do not manufacture round nuts in exotic materials such as titanium, Inconel, Hastelloy, or Monel. Our material capability covers carbon and alloy steels, stainless steels, brass, copper, aluminium, and specialist bronzes. For exotic materials, we recommend specialist suppliers.

26. How do hook spanners engage bearing lock nuts?

Hook spanners feature pins, hooks, or lugs that engage the external radial slots machined around the bearing lock nut's face. The spanner hook fits into a slot, and rotation of the spanner tightens or loosens the nut. Multiple slots provide alternative engagement points for precise torque application.

27. Can you make round nuts with left-hand threads?

Yes, we manufacture round nuts with left-hand threads across all sizes and types—metric, imperial, and unified. Left-hand threads are used in anti-loosening applications (components rotating clockwise), turnbuckles (one end LH, other RH), and specialised assemblies where conventional right-hand threads would unwind.

28. What is the maximum torque that can be applied to a round nut?

Maximum torque depends on the round nut type, diameter, material, thread size, and tightening method. Plain smooth round nuts have limited torque capacity (hand pressure only). Slotted nuts (DIN 546) allow moderate torque with screwdrivers. Round nuts with holes (DIN 547/548) and bearing lock nuts with hook spanners can handle significantly higher torques approaching that of hexagon nuts in similar sizes and materials.

29. Do you manufacture round nuts for cleanroom environments?

Yes, we can manufacture round nuts in stainless steel 316 or 303 with electropolishing for cleanroom applications. Stainless steel resists corrosion, doesn't shed particles, and can be easily cleaned and sterilised, making it suitable for pharmaceutical, semiconductor, and medical cleanrooms.

30. Can round connector nuts have sight holes?

Yes, round connector nuts can be machined with sight holes (viewing holes) drilled through the wall at the mid-length position. Sight holes allow visual verification that both mating threads have fully engaged inside the connector nut. They can also be used to insert a rod or pin to assist in tightening or positioning.

31. What quality standard do you manufacture to?

We are accredited to ISO 9001:2015, ensuring our quality management system meets international standards. Round nuts are manufactured to applicable DIN, BS, or ISO specifications (or customer drawings), with full dimensional inspection, thread gauging, and material traceability.

32. Can you manufacture round nuts with fine or extra-fine pitch threads?

Yes, we manufacture round nuts in coarse (standard), fine, and extra-fine pitch threads across metric, imperial, and unified ranges. Fine pitch threads provide better adjustment precision, increased tensile stress area, and improved vibration resistance compared to coarse threads.

33. Are round nuts reusable?

Plain round nuts, slotted nuts, and knurled nuts are fully reusable if not mechanically deformed. Round nuts with nylon inserts can be reused a limited number of times (typically 5-10 installations) before the nylon wears. Round nuts with all-metal prevailing torque features (thread deformation) have limited reuse capability. Bearing lock nuts are reusable if not damaged during installation/removal.

34. Can round nuts be supplied with metric threads and imperial dimensions?

Yes, we can manufacture round nuts with metric internal threads (e.g., M12 × 1.75) and imperial external diameter dimensions (e.g., 3/4" OD). This is sometimes required when retrofitting metric threaded components into imperial-dimensioned assemblies or panels.

35. Do you manufacture round nuts to obsolete DIN standards?

Yes, we manufacture round nuts to obsolete or superseded DIN specifications when referenced on customer drawings or required for heritage projects. Many legacy designs still reference older DIN standards. We ensure dimensional compatibility whilst applying current material and quality standards where appropriate.

36. What is the delivery time for custom round nuts?

Lead time depends on complexity, quantity, and material availability. Simple custom round nuts in common materials: 1-2 weeks for small quantities. Standard DIN 546/547/548 nuts in common sizes and materials: often available within 3-5 working days. Complex multi-feature nuts or exotic materials: 3-4 weeks. Contact us for specific lead time quotes.

37. Can you manufacture round nuts with internal threads tapped oversize?

Yes, we can tap round nuts with oversize threads—typically 0.1mm to 0.5mm over nominal diameter. Oversize threads accommodate worn or damaged mating threads, common in restoration or repair applications. Specify the oversize amount and we will machine accordingly.

38. Do you offer rush or expedited manufacturing for urgent round nut requirements?

Yes, we can prioritise urgent orders for rush delivery when machining capacity allows. Contact us with your requirement and deadline—we'll advise if expedited production is feasible. Rush service may incur additional charges depending on the extent of prioritisation required.

39. Can round nuts be machined from customer-supplied material (free-issue)?

Yes, we offer free-issue machining where you supply the raw material (round bar) and we manufacture the round nuts. This is useful when you have specific material grades, certifications, or existing stock. Ensure material is suitable diameter for the finished nut size plus machining allowances.

40. What standards apply to bearing lock nuts?

Bearing lock nuts with hook spanner engagement are typically manufactured to ISO 2982 (inch series) or DIN 981/DIN 70852 (metric shaft nuts). These standards specify dimensions, slot configurations, and tolerances for nuts used in bearing mounting applications.

41. Can you add identification markings to round nuts?

Yes, we can add identification markings including part numbers, material codes, size markings, or company logos. Marking methods include laser engraving (permanent, precise), stamping (for larger nuts), or electro-etching. Laser marking is preferred for small round nuts and precise identification requirements.

42. Do you manufacture round nuts with conical or radiused seats?

Yes, we can machine round nuts with conical bearing faces (various angles) or radiused seats to mate with spherical washers or curved surfaces. This is useful in assemblies where the bearing surface is not perpendicular to the thread axis, allowing angular adjustment.

43. Can round nuts be made with external threads?

Round nuts are internally threaded by definition. If you require a round component with external threads, this would be a boss, spigot, or cylindrical stud. We can manufacture these components—contact us with your drawing or specification.

44. What is the difference between DIN 467 and DIN 466 knurled nuts?

DIN 467 specifies flat (low profile) knurled nuts, typically 0.5d to 0.6d in height (where d = nominal diameter). DIN 466 specifies high knurled nuts, typically 0.8d to 1.0d in height, similar to standard full nut height. High knurled nuts provide more thread engagement and greater strength.

45. Can you manufacture round nuts in aluminium for weight-critical applications?

Yes, we manufacture round nuts in various aluminium grades including 6082-T6 (good strength, excellent machinability), 6061-T6 (aircraft-quality), 2014-T6 (aerospace structural), and 7075-T6 (premium aerospace grade). Aluminium round nuts are ideal for weight reduction in aerospace, motorsport, and portable equipment.

46. Do you provide CAD models or technical drawings of round nuts?

For standard DIN 546/547/548 nuts, dimensions are defined by the applicable standard. For custom round nuts, we can provide technical drawings showing dimensions, tolerances, and features. CAD models (STEP, IGES formats) can be supplied on request for design integration purposes.

47. Can round nuts be manufactured with through-holes for wire locking?

Yes, we can drill radial holes through round nuts for wire locking (safety wire). Specify hole diameter (typically 1mm to 2mm for small nuts, up to 3mm for larger sizes), position, and number of holes (commonly two holes 180° apart or three holes 120° apart for redundancy).

48. What is the typical wall thickness for round nuts?

Wall thickness (external diameter minus thread major diameter, divided by 2) depends on the application and stress requirements. Typical wall thickness is 1.5mm to 3mm for small nuts (M3-M10), 3mm to 6mm for medium nuts (M12-M24), and 6mm to 10mm for large nuts (M30-M52). Thicker walls increase strength but add weight and material cost.

49. Can you manufacture round nuts with captive washers?

We can machine round nuts with integral flanges (which function similarly to captive washers), but we do not typically assemble round nuts with separate captive washers. If you require a round nut with a permanently attached washer, describe your requirement and we'll advise on the best manufacturing approach.

50. Do you manufacture round nuts to customer samples?

Yes, we regularly manufacture round nuts from customer samples. Send us your sample nut and we will reverse-engineer dimensions, identify thread type and pitch, determine material (if possible), and quote manufacturing to match. This is particularly useful for obsolete or unmarked nuts in restoration projects.

51. Can you supply round nuts with certificates of conformity?

Yes, we provide Certificates of Conformity confirming that manufactured round nuts meet specified standards (DIN 546/547/548, etc.), material grades, dimensions, and finish requirements. Certificates include batch traceability, manufacturing date, and inspector identification.

52. What happens if a round nut thread is damaged during installation?

Thread damage during installation usually results from cross-threading, excessive torque, misalignment, or debris in the threads. Prevention includes ensuring proper alignment before tightening, using lubricant when specified, applying torque gradually, and inspecting threads before assembly. Damaged threads may be reparable by retapping oversize, but replacement is often more cost-effective.

53. Can you manufacture round nuts with external knurling and internal threads simultaneously?

Yes, knurled nuts feature external knurling on the cylindrical surface and internal threads—this is standard for DIN 6303/467/466 knurled nuts. Knurling is applied after turning the external diameter and before or after tapping, depending on the manufacturing sequence that best maintains dimensional accuracy.

54. Do round nuts require washers?

Round nuts often do not require washers when the bearing surface is adequate. However, washers may be beneficial when the bearing surface is soft or uneven, when load distribution needs to be increased, when the hole is oversize, or when electrical insulation is required. Flanged round nuts have integral bearing surfaces and typically eliminate the need for separate washers.

55. Can you manufacture round nuts with interference fit (press-fit) external diameters?

Yes, round nuts can be manufactured with precision external diameters for interference fit (press-fit) installation into panels, castings, or housings. Specify the mating hole diameter and required interference (typically 0.01mm to 0.05mm depending on material and diameter). These are often called press-fit boss nuts or insert nuts.

56. What testing do you perform on round nuts?

We perform dimensional inspection (external diameter, thickness, hole positions measured with callipers, micrometers, and CMM when required), thread gauging using ISO 1502/BS 3643 go/no-go gauges, visual inspection for surface finish and defects, and material verification (material certificates for critical applications). Torque testing, salt spray testing, and mechanical property testing available on request.

57. Can round nuts be manufactured with left-hand threads on one end and right-hand on the other?

Round connector nuts can feature left-hand threads one end and right-hand threads the other end, commonly used in turnbuckle assemblies. Standard round nuts have a single thread form throughout, so mixed LH/RH only applies to elongated connector nut configurations.

58. Do you manufacture round nuts in brass for electrical applications?

Yes, brass round nuts (typically CZ121/CW614N free-cutting brass) are commonly used in electrical applications due to excellent electrical conductivity, corrosion resistance, non-magnetic properties, and attractive appearance. Brass is ideal for switchgear, control panels, and earthing/bonding applications.

59. What are the advantages of round nuts over hexagon nuts?

Round nuts offer smooth aesthetics without protruding corners, ability to fit through round holes or recesses, protection from accidental hand-loosening (when using slotted or hole types), suitability for applications requiring free rotation until final tightening, minimal snagging risk, and better aesthetics in visible assemblies. However, hexagon nuts provide easier tool access and higher torque capacity.

60. Can you supply round nuts in small quantities for prototyping?

Yes, we manufacture round nuts from single prototype units upwards. Our CNC bar-turning process is cost-effective for prototypes and small batches without requiring expensive tooling or minimum order quantities. Prototype costs are typically higher per unit than production quantities, but we offer competitive pricing at all volumes.

61. Do you offer design assistance for custom round nut applications?

Yes, our experienced team can advise on material selection, dimension optimisation, feature integration (slots, holes, knurling, flanges), thread specifications, finish selection, and manufacturing feasibility. Contact us during your design phase and we'll help ensure your round nut design is manufacturable and fit for purpose.

62. Can round nuts be made with Acme or trapezoidal threads?

Yes, we can manufacture round nuts with Acme threads (29° included angle), trapezoidal threads (30° included angle per ISO 2904 or DIN 103), or other non-standard thread forms. These threads are used in lead screws, adjustment mechanisms, and low-friction high-load applications.

63. What is the typical lead time for standard DIN round nuts?

Standard DIN 546/547/548 round nuts in common sizes (M4 to M16) and materials (steel, stainless, brass) are typically available within 3-5 working days for small quantities, 1-2 weeks for larger batches. Less common sizes or materials may require 2-3 weeks. Contact us for specific availability on your required specification.

64. Can you manufacture miniature round nuts for precision instruments?

Yes, we manufacture miniature round nuts from M1.4 upwards and BA thread sizes down to 6BA or smaller. Miniature round nuts are used in precision instruments, watch mechanisms, optical equipment, and electronics assemblies requiring small, precise, hand-tightenable fasteners.

65. Do you supply round nuts with corrosion test certificates?

Yes, we can supply round nuts with corrosion test certificates including salt spray test results (ASTM B117 neutral salt spray test, specifying hours to red rust for zinc-plated parts), humidity test results, or other environmental exposure test data when specified. Testing is typically performed by third-party UKAS-accredited laboratories.

66. Can round nuts be supplied pre-assembled with O-rings or seals?

We manufacture round nuts but do not typically assemble them with O-rings or seals. If you require round nuts with sealing features, we can machine grooves or recesses to accommodate O-rings, but assembly of the seal is generally performed during your final installation.

67. What is the difference between boss nuts and rivet nuts?

Boss nuts are round nuts with flanges or collars, typically welded or press-fitted for permanent installation, and feature standard tapped threads. Rivet nuts (also called nutserts or riv-nuts) are thin-walled cylindrical nuts with collapsible bodies that are installed using a rivet gun, creating a permanent threaded insert by mechanical deformation. We manufacture boss nuts; we do not manufacture rivet nuts.

68. Can you manufacture round nuts with drilled and tapped holes for mechanical attachments?

Yes, we can drill and tap round nuts radially (through the wall) or axially (from the face) for attachment of mechanical components, locking grub screws, or mounting brackets. Specify the hole location, size, thread type, and depth, and we will incorporate this into the machining process.

69. Do you provide volume discounts for large round nut orders?

Yes, pricing improves with quantity due to economies of scale in material purchasing, optimised manufacturing setup, and reduced per-unit inspection time. Request a quotation with your volume requirements and we will provide competitive tiered pricing.

70. Can round nuts be manufactured in phosphor bronze for marine applications?

Yes, we manufacture round nuts in phosphor bronze (PB102) which offers excellent corrosion resistance in marine environments, good strength, and resistance to dezincification. Phosphor bronze is ideal for marine hardware, pumps, valves, and anywhere salt water or brackish water exposure occurs.

71. What information do you need for a round nut quotation?

Please provide thread size and pitch (e.g., M10 × 1.5), external diameter, thickness (height), type (plain, slotted DIN 546, with holes DIN 547/548, knurled), material and finish, quantity required, and any special features (flanges, cross-drilled holes, left-hand threads). A drawing is ideal for custom nuts. We can also quote from samples.

72. Can you manufacture round nuts with tapered internal threads (pipe threads)?

Yes, we can manufacture round nuts with British Standard Pipe (BSP) tapered threads, including BSPT (tapered pipe thread) and BSPP (parallel pipe thread). These are used in plumbing, pneumatics, and hydraulic applications. Internal taper threads require specialised taps and inspection gauges.

73. Do you manufacture round nuts for food processing or pharmaceutical industries?

Yes, we manufacture round nuts in 316 stainless steel (A4) or 304 stainless steel (A2) suitable for food processing and pharmaceutical applications. These materials resist corrosion from cleaning chemicals, sterilisation processes, and food acids. We can provide material certification and surface finish documentation when required.

74. Can round nuts be supplied with controlled torque specifications?

Round nuts can be specified with torque requirements, but the achievable torque depends on the nut type, material, thread size, and tightening method. We can provide torque-angle curves or breakaway torque data for round nuts with prevailing torque features (nylon inserts or thread deformation).

75. What are the weight differences between round nuts and hexagon nuts?

Round nuts are typically lighter than equivalent hexagon nuts because the cylindrical profile has less material than the hex across-flats dimension. Weight saving percentage depends on the specific dimensions but is generally 15-30% lighter. This can be significant in aerospace or high-volume automotive applications.

76. Can you manufacture round nuts with captive pins or tommy bars?

We manufacture round nuts with holes for pin or tommy bar insertion (DIN 547/548 type), but we do not supply the pins or tommy bars themselves. These tools are typically purchased separately or fabricated from silver steel or dowel pins to suit your specific round nut and application.

77. Do you manufacture round nuts to ASME or ANSI standards?

Our primary manufacturing standards are DIN, BS, and ISO. We do not typically manufacture to ASME B18.2.2 or other American standards. However, we can manufacture round nuts to customer drawings or specifications that reference ASME/ANSI dimensions, materials, and tolerance requirements.

78. Can round nuts be supplied with thread locking compounds pre-applied?

We do not typically pre-apply thread locking compounds (e.g., Loctite) to round nuts because these compounds have limited shelf life and may require specific application conditions. We recommend you apply thread locker during assembly according to the manufacturer's instructions for optimal performance.

79. What is the temperature range for knurled nuts with nylon inserts?

Knurled nuts with nylon inserts (typically Nylon 66) are suitable for continuous service temperatures from -30°C to +95°C. Short-term exposure up to +120°C is possible, but prolonged exposure causes thermoplastic deformation of the nylon ring, reducing locking effectiveness. For higher temperatures, specify all-metal prevailing torque features.

80. Can you reverse-engineer round nuts from photographs?

Photographs alone are insufficient for accurate manufacturing. We require either a physical sample (which we can measure), a dimensioned drawing, or detailed specifications including external diameter, thickness, thread size, hole positions/sizes, and material. Photographs can support enquiries but cannot substitute for dimensional data.

81. Do you manufacture round nuts for vacuum applications?

Yes, round nuts for vacuum applications are typically manufactured in stainless steel 303 or 316 with careful attention to surface finish and cleanliness. We can supply vacuum-cleaned nuts suitable for high-vacuum or ultra-high-vacuum environments used in semiconductor processing, scientific instruments, and particle accelerators.

82. Can round nuts be supplied with thread inserts for improved wear resistance?

We manufacture solid round nuts with integral threads. We do not install separate thread inserts (HeliCoil-type). If your application requires exceptional wear resistance, we recommend specifying harder material grades (stainless steel, hardened steel, or bronze) rather than using thread inserts in softer materials.

83. What tolerance do you maintain on slotted round nut (DIN 546) slot widths?

DIN 546 specifies slot width tolerances. For example, M6 × 1 DIN 546 has a nominal slot width of 2.5mm with tolerance range +0.31/-0.06mm (2.44mm to 2.81mm). We manufacture to standard tolerances unless tighter tolerances are specified for precision screwdriver fit.

84. Can you manufacture round nuts with internal splines or lobes?

We manufacture round nuts with internal threads only. Internal splines or lobes (like Torx or multi-lobe profiles) would not be classified as nuts. If you require internally splined components, please contact us with your specification and we'll advise on manufacturing feasibility.

85. Do you supply round nuts to the railway industry?

Yes, we supply round nuts for railway applications including rolling stock interiors, signal equipment, track fixtures, and heritage railway restoration. Materials typically specified include stainless steel 316 (corrosion resistance), brass (electrical components), and galvanised steel (outdoor fixtures). We can provide material certification and compliance documentation when required by railway specifications.

Contact Us for Round Nut Manufacturing

For quotations, technical enquiries, or to discuss your specific round nut requirements, please contact Trojan Special Fasteners Ltd:

- *Address:* 18 Fortnum Close, Kitts Green, Birmingham, B33 0LG, United Kingdom

- *Telephone:* 0121 789 8586

- *Email:* sales@trojansf.co.uk

We manufacture in Birmingham, supplying the UK, Europe, and international markets with precision round nuts to exacting specifications.

Related Products

- Hexagon Nuts: Standard six-sided nuts for maximum versatility and tool access

- Square Nuts: Four-sided nuts providing excellent grip and anti-rotation

- Nylon Insert Nuts: Self-locking nuts with polymer inserts for vibration resistance

- All-Metal Prevailing Torque Nuts: High-temperature locking nuts with mechanical thread deformation

- Flange Nuts: Nuts with integral flanges for increased bearing surface area

- Castle and Slotted Nuts: Positive locking nuts for cotter pin or wire locking

- Dome and Cap Nuts: Aesthetic blind nuts for covering and protecting threads

- Connector Nuts: Elongated coupling nuts for joining threaded rods

- Wing Nuts: Hand-tightened nuts with protruding wings for tool-free operation

- Special Nuts: Custom-manufactured nuts to your drawings and specifications

See Also:

- Materials: Comprehensive guide to ferrous and non-ferrous materials

- Surface Finishes: Information on plating, coating, and finishing options

- Technical Standards: Details of BS, DIN, ISO, and ASTM fastener specifications

- Services: Free-issue machining, tapping, polygon turning, and custom operations