All Metal Prevailing Torque Nuts

All-Metal Prevailing Torque Nuts

All-Metal Prevailing Torque Nuts: Complete Manufacturing Guide

Trojan Special Fasteners Ltd manufactures precision all-metal prevailing torque nuts to customer specifications across multiple material and finish combinations. Based in Birmingham, UK, we've supplied industries with high-performance locking fasteners for over 31 years.

What Are All-Metal Prevailing Torque Nuts?

All-metal prevailing torque nuts are self-locking fasteners that resist loosening under vibration, shock, and dynamic loads without requiring additional locking devices such as lock washers or split pins. Unlike nylon insert nuts, these fasteners achieve their locking action through permanent mechanical deformation of the nut body or threads, making them suitable for high-temperature applications up to 750°C (1,400°F).

The locking mechanism creates friction between the nut and mating bolt threads, requiring increased torque during both assembly and removal. This "prevailing torque" prevents self-loosening whilst maintaining the ability to be removed and reused-typically 3 to 5 times before performance degrades significantly.

Key Advantages of All-Metal Prevailing Torque Nuts

- Superior temperature resistance (up to 750°C)

- Chemical resistance in corrosive environments

- No plastic components that can degrade

- Effective vibration resistance

- Reusable for multiple assembly cycles

- Compliant with international standards (ISO, DIN, BS, ANSI)

- Available in various material grades and finishes

European Property Classes and Material Grades

All-metal prevailing torque nuts manufactured to European standards are classified by property class, which defines the mechanical properties including tensile strength, proof load, and hardness. This system differs from the American "grade" system and provides precise specification for engineering applications.

Common European Property Classes:

Property Class 5:

- Proof stress: 500 N/mm²

- Typical material: Low/medium carbon steel

- Applications: General industrial use, non-critical assemblies

- Equivalent to: Approximately Grade 2 or Grade A in American standards

Property Class 8:

- Proof stress: 800 N/mm²

- Typical material: Medium carbon steel, quenched and tempered

- Applications: Most industrial and automotive applications

- Equivalent to: Approximately Grade 5 or Grade C in American standards

- Most commonly specified class for general engineering

Property Class 10:

- Proof stress: 1,000 N/mm²

- Typical material: Alloy steel, quenched and tempered

- Applications: High-stress applications, heavy machinery, aerospace

- Equivalent to: Approximately Grade 8 in American standards

Property Class 12:

- Proof stress: 1,200 N/mm²

- Typical material: High-alloy steel, quenched and tempered

- Applications: Extreme loading, critical assemblies, aerospace

- Equivalent to: Higher than Grade 8 in American standards

Property classes are defined in BS EN ISO 898-2 (Mechanical properties of fasteners made of carbon steel and alloy steel - Part 2: Nuts with specified property classes). This standard superseded the older BS 3692 and provides harmonisation across the European Union.

Corrosion-Resistant Grades:

Austenitic Stainless Steel:

- 303, 304 (A2): General corrosion resistance, non-magnetic

- 316, 316L (A4): Superior corrosion resistance, marine-grade

- Property classes: Typically 50 or 70 (e.g., A2-70, A4-80)

- Temperature range: -200°C to +400°C continuous

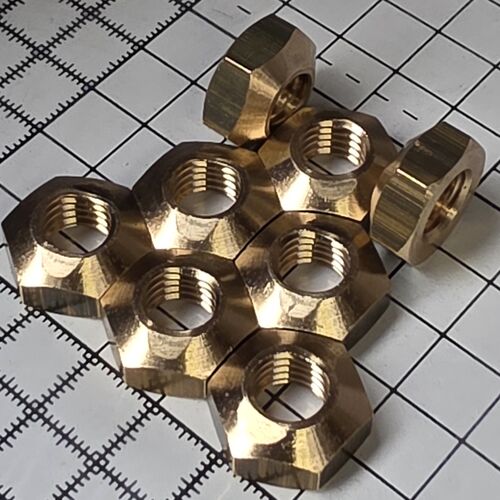

Brass and Bronze:

- CZ121 (CW614N): Excellent electrical conductivity, non-sparking

- Phosphor Bronze: Superior corrosion resistance, marine applications

- Applications: Electrical equipment, intrinsically safe environments, marine hardware

Material specifications follow European Norms (EN) including:

- EN 10025: Hot rolled products of structural steels

- EN 10083: Steels for quenching and tempering

- EN 10088: Stainless steels

- EN 10204: Metallic materials inspection certificates (3.1 certificates available)

Types of All-Metal Prevailing Torque Locking Mechanisms

All-metal prevailing torque nuts rely on controlled deformation to create the locking action. Trojan Special Fasteners manufactures nuts utilising various proven locking mechanisms based on customer drawings and specifications.

Important: Trojan Special Fasteners Ltd does not manufacture patented or trademarked items. We produce similar functional equivalents based on customer-supplied drawings that incorporate the locking principles described below.

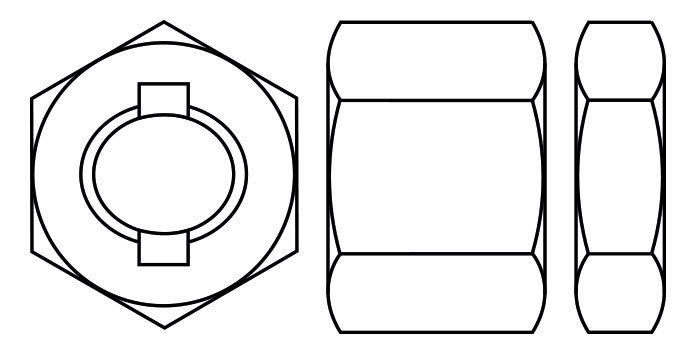

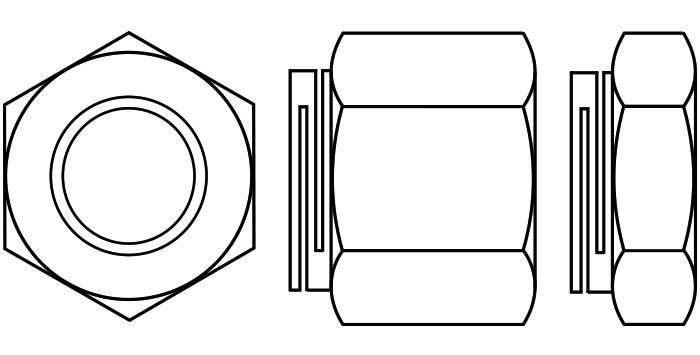

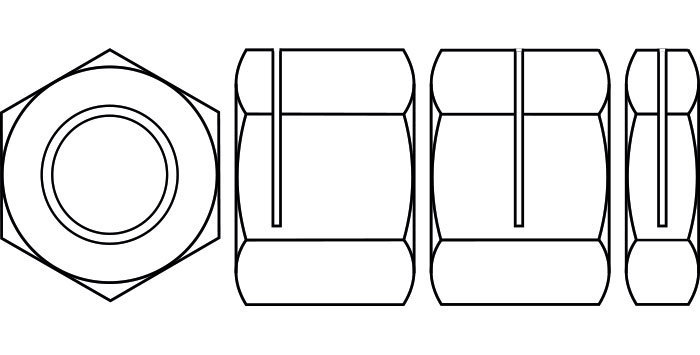

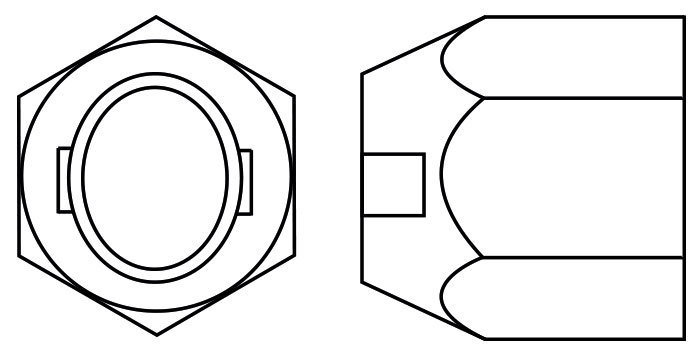

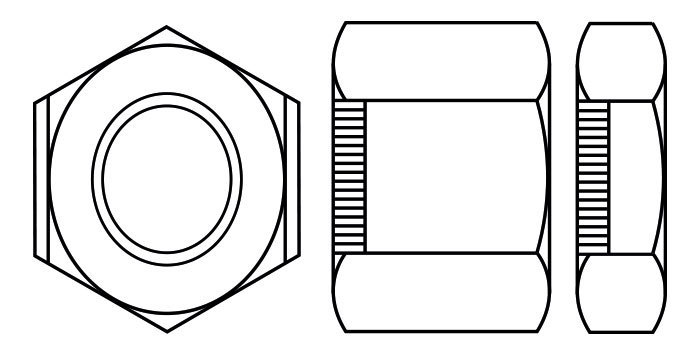

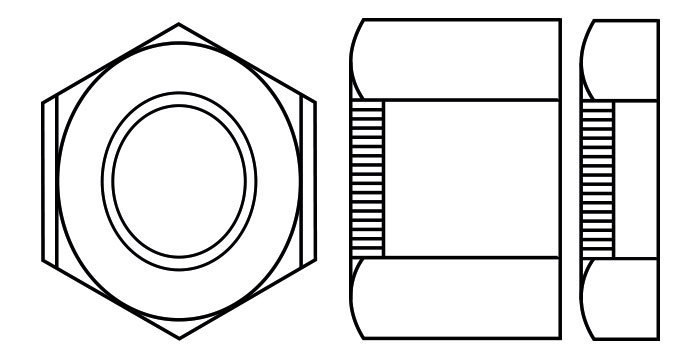

Elliptically Deformed Thread Nuts

These nuts feature a conical section that is mechanically deformed at two or more points, creating an elliptical thread profile. When threaded onto a bolt, the deformed threads generate increased friction and prevailing torque.

Common names for this type include:

- Automation lock nuts

- Autolock nuts

- Conelock nuts

- Crownlock nuts

- Philidas MKV or MK5 nuts

- Stover nuts

- Unitorque nuts

These nuts are non-reversible and must be installed with the conical section facing upward (not cone-first). The degree of deformation determines the prevailing torque value-greater deformation creates higher locking force but also increases installation and removal torque.

British and European standards covering this type include:

- BS EN ISO 7042:2012 - All-metal hexagon high nuts, property classes 5, 8, 10 and 12

- BS EN ISO 7719:2012/2025 - All-metal hexagon regular nuts, property classes 5, 8 and 10

- BS ISO 7720:2012 - All-metal hexagon nuts, Style 2, property class 9

- BS 4929-1 - Prevailing torque hexagon nuts, metric series (metallic locking element)

- DIN 980 - All-metal prevailing torque hexagon nuts (superseded by ISO 7042 but widely referenced)

- EN 1664 - All-metal prevailing torque hexagon nuts with flange

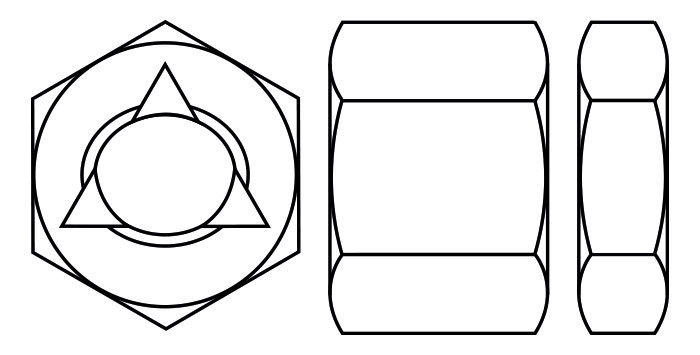

Tri-Lock Configuration

A European variation of the elliptical deformation where the cone is deformed into an obround triangle, creating three deformation points instead of two. This provides more uniform thread contact and consistent prevailing torque around the circumference. Popular in German and French automotive applications.

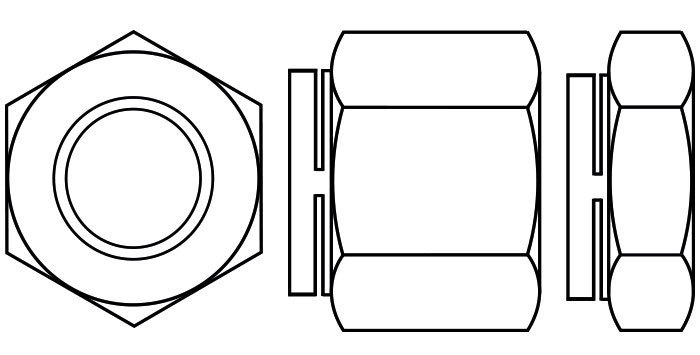

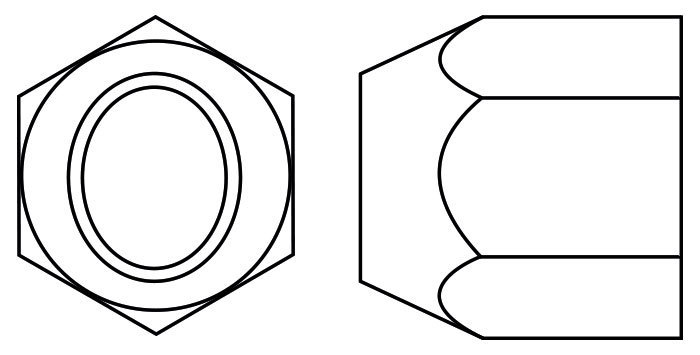

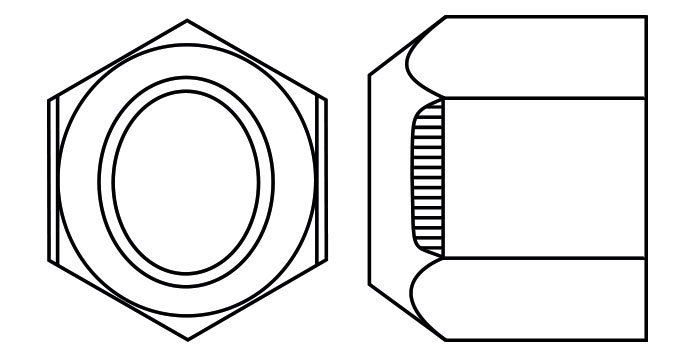

Collar-Deformed Nuts

Instead of a conical section, these nuts feature a cylindrical collar at the top. The collar is deformed across its height, forcing elliptical deformation of the threads below. This design is sometimes called a "Cleveloc" type configuration. Common in French industrial applications conforming to NF standards.

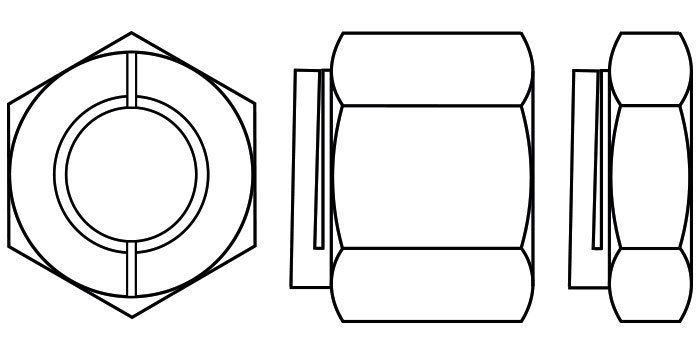

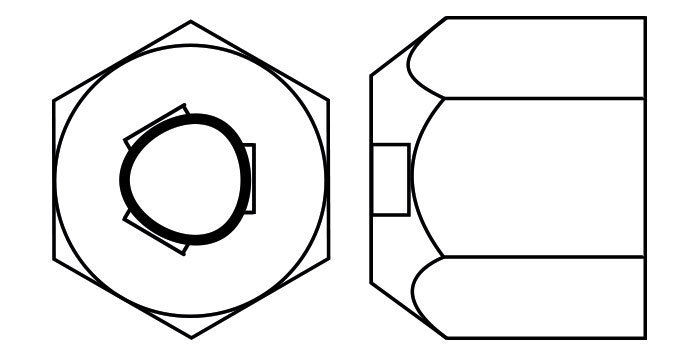

Top-Section Deformed Nuts

These nuts achieve thread deformation by mechanically pinching the top section of the nut body at two points, without requiring a distinct cone or collar. The deformation extends into the first few threads, creating the prevailing torque effect. Popular in British and Scandinavian markets.

Top Lock and Tri-Lock Nuts (Axial Deformation)

The top one or two threads are deformed downward from above, creating interference with mating threads. These are non-reversible and provide reliable locking action throughout the nut's engagement length.

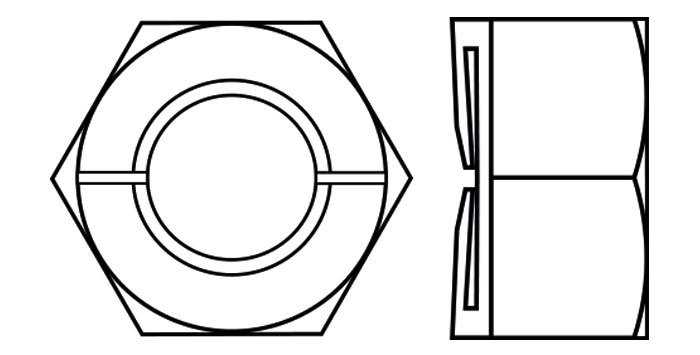

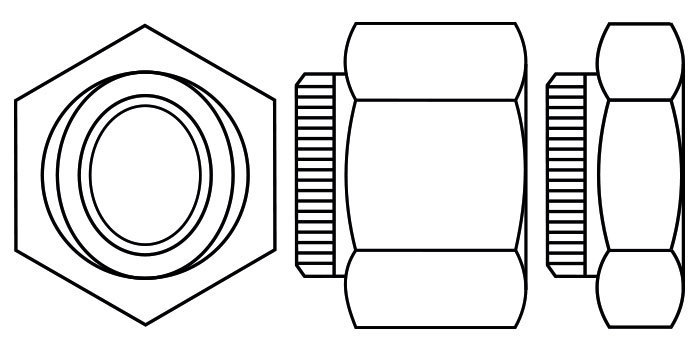

Slotted, Split Beam and Split Nut Designs

These proprietary designs incorporate axial slots either in a crown section (Philidas and Aerotight types) or within the nut body itself (typically at 0.5h or 0.66h of the nut height). The slots allow sections of the nut to deflect during installation, creating spring-like pressure on the bolt threads.

When installed, the displaced sections are forced back toward their original position, generating continuous radial pressure and prevailing torque. These designs are particularly effective in applications requiring consistent locking force.

Slotted Crown Designs (French Aerospace) are proprietary designs incorporating axial slots in a crown section, particularly common in French aerospace applications (Airbus, Safran, Dassault) conforming to NF E25-411 standards. The slots allow sections of the nut to deflect during installation, creating spring-like pressure on the bolt threads.

When installed, the displaced sections are forced back toward their original position, generating continuous radial pressure and prevailing torque. These designs are particularly effective in aerospace applications requiring consistent locking force.

Materials and Finishes Available

Trojan Special Fasteners manufactures all-metal prevailing torque nuts in:

Materials:

- Carbon steel (various grades, EN1A, EN8, EN16T, EN19T, B7 etc)

- Stainless steel (303, 304, 316, 316L, A4-70, A4-80)

- Brass (CZ112, CW614N, CZ121 and others)

- Bronze such as CA104, PB102 and NES833

- Copper alloys

- Aluminium alloys

Surface Finishes (European Standards):

- Bright zinc plated to ISO 2081 (Fe/Zn 5-8μm)

- Yellow zinc chromate to ISO 4042

- Hot-dip galvanised to EN ISO 1461 (minimum 45μm)

- Black oxide to ISO 11408

- Phosphate and oil to ISO 9717

- Cadmium plating (where permitted under REACH)

- Nickel plating to EN ISO 1458

- Zinc-nickel alloy (RoHS compliant alternative to cadmium)

- Parkerizing

- Plain/self-colour

- PTFE coating (particularly for stainless steel galling prevention)

- Delta-Tone® coating (zinc-aluminium flake, automotive OEM approved)

- Geomet® coating (zinc-aluminium flake, high corrosion resistance)

All finishes comply with EU REACH and RoHS directives. Material certificates to EN 10204 3.1 available upon request.

International Standards and Specifications

We prioritise UK and European specifications, supporting British and Continental manufacturing. In addition to machining all metal prevailing torque locking nuts to your dimensions, sample or drawing, Trojan Special Fasteners manufactures all-metal prevailing torque nuts to the comprehensive range of British, European harmonised, and international standards below.

ISO Standards (International Organisation for Standardisation):

| STANDARD | DESCRIPTION |

|---|---|

| ISO 2320 | Functional properties testing standard for all prevailing torque steel nuts (all-metal and nylon insert types) |

| ISO 7042 | All-metal prevailing torque hexagon nuts, Style 2 |

| ISO 7044 | All-metal prevailing torque hexagon nuts |

| ISO 7719 | All-metal prevailing torque hexagon nuts, Style 1 |

| ISO 7720 | All-metal prevailing torque hexagon nuts, Style 2 |

| ISO 10513 | All-metal hexagon high nuts with fine pitch thread, property classes 8, 10, 12 |

| ISO 12126 | All-metal prevailing torque hexagon flange nuts |

DIN Standards (Deutsches Institut für Normung - German):

| STANDARD | DESCRIPTION |

|---|---|

| DIN 267-27 | Testing method for prevailing torque characteristics |

| DIN 980 | All-metal prevailing torque hexagon nuts (superseded by ISO 7042 but still widely referenced) |

| DIN 6925 | All-metal prevailing torque hexagon nuts |

| DIN 6927 | All-metal prevailing torque hexagon flange nuts |

BS Standards (British Standards):

| STANDARD | DESCRIPTION |

|---|---|

| BS 4929-1 | Prevailing torque hexagon nuts - Metric series (covers both metallic and non-metallic locking elements) |

| BS 4929-2 | Prevailing torque hexagon nuts - Unified (inch) series (covers both metallic and non-metallic locking elements) |

BS EN ISO Standards (British adoption of European harmonised ISO standards):

| STANDARD | DESCRIPTION |

|---|---|

| BS EN ISO 2320 | Functional properties testing for all prevailing torque steel nuts (covers both all-metal and nylon insert types) |

| BS EN ISO 7042:2012 | All-metal hexagon high nuts - Property classes 5, 8, 10 and 12 |

| BS EN ISO 7719:2012/2025 | All-metal hexagon regular nuts - Property classes 5, 8 and 10 |

| BS EN ISO 10513:2012 | All-metal hexagon high nuts with fine pitch thread - Property classes 8, 10 and 12 |

BS ISO Standards (British adoption of ISO standards):

| STANDARD | DESCRIPTION |

|---|---|

| BS ISO 7720:2012 | All-metal hexagon nuts, Style 2 - Property class 9 |

EN Standards (European Norm):

| STANDARD | DESCRIPTION |

|---|---|

| EN 1664 | All-metal prevailing torque hexagon nuts |

| EN 1667 | All-metal prevailing torque hexagon nuts |

ASME/ANSI Standards (American Society of Mechanical Engineers/American National Standards Institute):

| STANDARD | DESCRIPTION |

|---|---|

| ASME B18.16.6 | Prevailing torque locknuts (inch series) - covers both nylon insert and all-metal hex grades A, B, C, F, G |

| ASME B18.16M | Prevailing torque metric hex nuts - Property classes 5, 9, 10 |

| ASME/ANSI B18.16.3M | All-metal prevailing torque hexagon nuts (metric) |

| ASME/ANSI B18.16.3M | All-metal prevailing torque hexagon flange nuts (metric) |

ASTM Standards (American Society for Testing and Materials):

| STANDARD | DESCRIPTION |

|---|---|

| ASTM A563 | Carbon and alloy steel nuts - Grades A, C, DH (structural applications with lock nut variants) |

| ASTM A194 | High-pressure/temperature nuts - Grade 2H commonly used as prevailing torque lock nuts |

IFI Standards (Industrial Fasteners Institute):

| STANDARD | DESCRIPTION |

|---|---|

| IFI 100/107 | Prevailing torque nuts unified threads - covers both all-metal and nylon insert types (superseded by ASME B18.16.6 but still referenced) |

NF Standards (Normes Françaises - French National Standards):

| STANDARD | DESCRIPTION |

|---|---|

| NF E25-410 | All-metal prevailing torque hexagon nuts - Property classes 5, 8, 10 |

| NF E25-411 | All-metal prevailing torque hexagon nuts with slot(s) - Symbol H FR |

| NF E25-414 | All-metal prevailing torque hexagon nuts with flange |

| NF E25-420 | All-metal prevailing torque hexagon nuts, Style 2 - Property classes 5, 8, 10, 12 |

| NF E25-421 | Prevailing torque hexagon flange nuts, Style 1 |

| NF E25-422 | Prevailing torque hexagon flange nuts, Style 2 |

| NF E25-507 | Prevailing torque hexagon flange nuts |

NF EN Standards (French adoption of European harmonised standards):

| STANDARD | DESCRIPTION |

|---|---|

| NF EN 1664 | All-metal hexagon nuts with flange (equivalent to ISO 7044) |

| NF EN 1667 | All-metal hexagon nuts with flange - Fine pitch thread |

| NF EN ISO 7042 | All-metal hexagon high nuts - Property classes 5, 8, 10, 12 (supersedes NF E25-420) |

SAE Standards (Society of Automotive Engineers):

| STANDARD | DESCRIPTION |

|---|---|

| SAE J995 | Mechanical and material requirements for steel nuts (automotive applications) |

| SAE J2283 | Mechanical requirements for one-piece wheel nuts |

| SAE AS1371 | Self-locking aerospace nuts, all-metal, high-temperature (up to 427°C/800°F) |

JIS Standards (Japanese Industrial Standards):

| STANDARD | DESCRIPTION |

|---|---|

| JIS B 1056 | Prevailing torque steel nuts - Functional properties |

| JIS B 1199-4 | Prevailing torque type all-metal hexagon nuts with flange |

JASO Standards (Japanese Automotive Standards Organization):

| STANDARD | DESCRIPTION |

|---|---|

| JASO F106 | Prevailing torque testing method for automotive fasteners |

Aerospace Standards (NAS/MS/NASM):

| STANDARD | DESCRIPTION |

|---|---|

| NAS | Various National Aerospace Standards for precision high-strength prevailing torque nuts |

| MS | Military Standard nuts (many converted to NASM specifications) |

| NASM | NAS-maintained standards retaining MS part numbers for aerospace applications |

We also manufacture non-preferred sizes, non-standard thread forms, and completely bespoke designs to customer drawings and specifications.

Prevailing Torque Standards and Testing

The locking performance of all-metal prevailing torque nuts is defined by international standards:

Performance Requirements:

- ISO 898-2: Mechanical properties of nuts - defines prevailing torque requirements for metric fasteners

- ASME B18.16.6: Prevailing torque requirements for inch series locknuts - covers both nylon insert and all-metal types (grades A, B, C, F, G for all-metal)

- ASME B18.16M: Prevailing torque requirements for metric nuts (property classes 5, 9, 10)

- IFI 100/107: Defines prevailing torque for unified (UNC/UNF) threads - covers both types (superseded by ASME B18.16.6 but still widely referenced)

- ASTM A563: Structural nut grades with prevailing torque variants (grades A, C, DH)

- ASTM A194: High-temperature/pressure nuts including Grade 2H

- SAE J995: Automotive steel nut requirements

- BS 4929: British Standard covering both metallic and non-metallic locking element types

- JIS B 1056: Japanese functional properties standard for prevailing torque steel nuts

- BS EN ISO 898-2:2012: Mechanical properties of nuts - defines prevailing torque requirements and proof loads for metric fasteners with specified property classes

- BS EN ISO 2320:2015: Functional properties testing for all prevailing torque steel nuts (metallic and non-metallic types)

- BS 4929-1:2009 & BS 4929-2:2009: British Standard covering prevailing torque nuts in both metric and inch series (metallic and non-metallic locking elements)

- DIN 267-27:2000: German testing method for prevailing torque characteristics

- EN 1664:2008 & EN 1667:1997: European Norms for flange-type prevailing torque nuts

Testing Methods (applicable to all prevailing torque types):

- ISO 2320 / BS EN ISO 2320: Comprehensive testing method for functional properties of all prevailing torque steel nuts

- JASO F106: Japanese automotive standard for prevailing torque testing

Note: No standardised prevailing torque values exist for BSW (British Standard Whitworth) and BSF (British Standard Fine) threads. Custom specifications must be agreed between manufacturer and customer.

Critical Installation Guidelines

To ensure optimal performance and prevent damage, follow these installation best practices:

1. Install nuts toward the end of the threaded portion

Extended travel along lengthy threads can damage either the nut's locking feature or the bolt threads. This is particularly important when working with fine-pitch metric threads.

2. Match material grades appropriately

High property class nuts (Class 10 or 12) must be paired with bolts of equal or higher property class (10.9, 12.9). A hardened nut will act like a thread-cutting die on softer bolts, destroying the male threads. See BS EN ISO 898-1 for bolt property classes.

3. Avoid interference fit threads

Tolerance class 5H nuts with 4h or tighter bolt threads combined with prevailing torque can cause galling (cold welding). Use tolerance class 6H nuts with 6g bolts (per ISO 965-1) for optimal performance.. Class 3 or tighter thread fits combined with prevailing torque can cause galling (cold welding). Use Class 2 threads or coarser for optimal performance.

4. Apply correct torque values

Standard bolt torque specifications from VDI 2230 or other European guidelines do not apply. You must add the prevailing torque value to the desired clamping torque to achieve proper bolt tension.

5. Install in correct orientation

Non-reversible designs (eg DIN980V cone-type nuts) must be installed with the conical section upward, not cone-first onto the bolt.

6. Consider reuse limitations

Each installation/removal cycle reduces the prevailing torque. Most all-metal prevailing torque nuts can be safely reused 3-5 times before requiring replacement. For critical applications in automotive or aerospace (per ISO/TS 16949 or AS/EN 9100 requirements), consider single-use only.

Applications and Industries

All-metal prevailing torque nuts are essential in applications where:

- High operating temperatures exceed nylon insert capabilities

- Exposure to solvents, fuels, or chemicals would degrade polymers

- Extreme vibration or shock loading is present (rail applications per EN 45545)

- Long-term reliability without maintenance is required

- Harsh environmental conditions exist (offshore per NORSOK standards)

Examples of the types of British and European Industries Served:

Automotive Sector:

- Jaguar Land Rover - engine assemblies, suspension systems

- Bentley Motors - luxury vehicle chassis and drivetrain

- BMW Group (UK plants) - body-in-white assemblies

- Mercedes-Benz (European plants) - exhaust systems

- Rolls-Royce Motor Cars - bespoke vehicle assemblies

- Lotus Cars - lightweight performance vehicle applications

- Commercial vehicle manufacturers (DAF, Scania, Volvo, MAN)

Aerospace and Defence:

- Airbus UK - wing assembly fasteners

- BAE Systems - military aircraft and vehicles

- Rolls-Royce Aerospace - jet engine components

- Leonardo UK - helicopter assemblies

- Safran Landing Systems - landing gear applications

- Cobham - aerospace systems and equipment

Rail and Rolling Stock:

- Network Rail - infrastructure maintenance

- Alstom UK - train and tram assemblies

- Bombardier Transportation - bogie assemblies

- Siemens Mobility - rolling stock manufacture

- Hitachi Rail - high-speed train assemblies

- London Underground - heritage and modern rolling stock

Construction and Agricultural Machinery:

- JCB - heavy machinery and attachments

- Perkins Engines (Caterpillar) - engine assemblies

- CNH Industrial - agricultural equipment

- Komatsu UK - earthmoving equipment

- Liebherr - crane assemblies

Power Generation:

- EDF Energy - nuclear power plant maintenance

- Siemens Energy - gas turbine assemblies

- Rolls-Royce Power Systems - generator sets

- Offshore wind turbine installations

- Combined heat and power (CHP) systems

Marine and Offshore:

- Offshore oil and gas platforms (North Sea)

- Shipbuilding (BAE Systems Naval Ships, Babcock)

- Marine propulsion systems

- Offshore wind installation vessels

- Port and harbour equipment

Industrial Machinery:

- Printing press manufacturers

- Textile machinery (historic mills maintenance)

- Food processing equipment

- Packaging machinery

- Material handling systems

Custom Manufacturing Capabilities

Trojan Special Fasteners specialises in bespoke fastener manufacturing. We can produce:

- Non-standard thread forms (metric, UNC, UNF, BSW, BSF, BA, custom)

- British Association (BA) threads for heritage electronics and instrumentation

- British Standard Whitworth (BSW) and British Standard Fine (BSF) for heritage restoration

- Cycle Engineers' Institute (CEI) threads for bicycle applications

- Special dimensions and tolerances to customer drawings

- Left-hand threads for rotating machinery applications

- Thin or thick nut profiles

- Oversized or undersized specifications

- Polygon forms (hexagon, square, or custom polygons turned from round bar stock)

- Combination nuts (flange nuts, weld nuts, cage nuts)

- Prototype quantities through to production volumes

Bring us your drawings, samples, or specifications, and our experienced team will provide a competitive quotation with realistic lead times.

Why Choose Trojan Special Fasteners?

- Over 31 years of precision fastener manufacturing experience

- Birmingham, UK based - supporting British manufacturing

- Flexible production from single prototypes to large batches

- Competitive pricing without compromising quality

- Expert technical support to help specify the right solution

- Fast turnaround times for urgent requirements

- Quality assured to BS, ISO, DIN, and ANSI standards

- Free-issue machining services available

- EN 10204 3.1 certification available for critical applications

- RoHS and REACH compliant finishes for EU export

Visit our Services Page to learn about our machining capabilities including tapping, slotting, polygon turning (hexagon from round), and thread modification services.

Frequently Asked Questions: All-Metal Prevailing Torque Nuts

General Questions About All-Metal Prevailing Torque Nuts

1. What is the difference between an all-metal prevailing torque nut and a nylon insert lock nut?

All-metal prevailing torque nuts use permanent mechanical deformation of the nut body or threads to create locking friction, whilst nylon insert nuts use a polymer insert that grips the bolt threads. The key differences are temperature capability (all-metal nuts work up to 750°C versus approximately 120°C for nylon) and chemical resistance (all-metal nuts resist solvents and fuels that dissolve nylon). Nylon insert nuts generally provide more consistent torque over multiple uses and are specified in most general engineering applications per BS EN ISO 10511.

2. How many times can an all-metal prevailing torque nut conforming to BS EN ISO standards be reused?

Typically 3 to 5 times, though this varies by design, property class, and application severity. Each removal cycle reduces the prevailing torque as the deformed threads or nut body gradually return toward their original shape. Monitor the installation torque; if it drops significantly below the specification in BS EN ISO 2320, replace the nut. For critical safety applications under ISO/TS 16949 (automotive) or AS/EN 9100 (aerospace), consider single-use only.

3. Can all-metal prevailing torque nuts be used in high-temperature applications?

Yes, this is their primary advantage over nylon insert types. All-metal prevailing torque nuts function reliably at temperatures up to 750°C (1,400°F), far exceeding the capabilities of nylon insert lock nuts which fail above approximately 120°C. They're ideal for exhaust systems (Euro 6 diesel emissions equipment), engine components, industrial furnaces, and other high-heat environments common in European manufacturing. For continuous high-temperature service, specify stainless steel 316 or exotic alloys per EN 10088.

4. Do all-metal prevailing torque nuts work in both directions?

Most designs conforming to DIN 980 and ISO 7042 are non-reversible and must be installed in a specific orientation (typically with the conical section or deformed section at the top). Installing them backwards (cone-first) will damage the locking feature and the nut will not function properly. Always verify the correct installation orientation before assembly. This applies to most European prevailing torque nut designs.

5. What torque value should I use when installing all-metal prevailing torque nuts?

You must add the prevailing torque value to your desired clamping torque. The total installation torque = clamping torque + prevailing torque. For example, if you need 50 Nm of bolt tension and the prevailing torque per ISO 2320 is 8 Nm, apply 58 Nm total. Prevailing torque values are specified in BS EN ISO 898-2 and ISO 2320 based on nut size and property class. European torque calculation follows VDI 2230 methodology with prevailing torque as an additional component.

6. Are all-metal prevailing torque nuts reusable in critical safety applications?

For safety-critical applications regulated under European directives (Machinery Directive 2006/42/EC, Pressure Equipment Directive 2014/68/EU), many engineers specify single-use only despite the nut's capability for reuse. The prevailing torque decreases with each cycle, and the risk of inadequate locking in a critical application generally outweighs the cost savings of reuse. Always follow your industry regulations, CE marking requirements, and engineering specifications. Aerospace applications under AS/EN 9100 typically mandate single-use.

7. What British and European standards govern all-metal prevailing torque nuts?

Primary British standards include BS 4929-1 (metric series) and BS 4929-2 (inch series). European harmonised standards include BS EN ISO 7042, BS EN ISO 7719, BS EN ISO 10513, EN 1664, and EN 1667. German standards include DIN 980 (superseded but widely referenced) and DIN 6927. French standards include the NF E25 series (410, 411, 414, 420-422). Testing procedures are covered by BS EN ISO 2320 and DIN 267-27. These standards define dimensions, tolerances, property classes, and prevailing torque values harmonised across the European Union.

8. Can you supply all-metal prevailing torque nuts in stainless steel?

Yes, Trojan Special Fasteners manufactures all-metal prevailing torque nuts in various stainless-steel grades conforming to EN 10088 including 303, 304 (A2), 316, and 316L (A4). Stainless steel nuts provide excellent corrosion resistance for marine, chemical processing, food industry applications, and offshore installations. We can also supply them with additional PTFE coating for enhanced galling resistance. Property classes for stainless typically follow the A2-50, A2-70, A4-70, A4-80 designation system per ISO 3506.

9. What is the difference between DIN 980 and ISO 7042 nuts?

ISO 7042 is the international standard that superseded DIN 980, though both specify Style 2 all-metal prevailing torque hexagon nuts with similar dimensional requirements. ISO 7042 is harmonised across Europe as BS EN ISO 7042 and provides broader property class coverage (5, 8, 10, 12). Many engineering drawings still reference "DIN 980V" as shorthand, particularly in German automotive and machinery sectors. Trojan Special Fasteners can manufacture to either specification. Both are functionally equivalent for most applications.

10. Why are all-metal prevailing torque nuts more expensive than standard hex nuts?

The additional manufacturing step of controlled mechanical deformation requires specialised tooling, skilled operators, and quality control testing to verify prevailing torque values per BS EN ISO 2320. The cost difference is justified by the elimination of separate locking devices (lock washers, split pins, lock wire) and the prevention of costly failures due to loose fasteners. For critical European applications under CE marking requirements or pressure equipment regulations, the reliability justifies the premium.

Technical Questions About Design and Performance

11. How does thread deformation create prevailing torque?

When the nut is deformed elliptically or the threads are distorted, the internal thread profile no longer perfectly matches the cylindrical bolt threads per ISO 965-1. As the nut is threaded onto the bolt, the threads must deflect elastically to accommodate each other, creating continuous radial pressure. This pressure generates friction that resists rotation in both directions. The degree of deformation is controlled during manufacture to achieve the prevailing torque values specified in BS EN ISO 2320.

12. What is the difference between BS EN ISO 7042 (Style 2) and BS EN ISO 7719 (Style 1)?

Style 1 nuts (ISO 7719) have a full hexagonal height (approximately 0.8D to 1.0D where D is nominal diameter) and are thicker, whilst Style 2 nuts (ISO 7042) are thinner with a reduced height (approximately 0.5D to 0.7D). Style 1 generally provides more thread engagement and higher prevailing torque values. The choice depends on space constraints and required performance. Style 2 is more common in automotive applications where space is limited.

13. Can all-metal prevailing torque nuts be used on left-hand threads?

Yes, the locking mechanism works equally well on left-hand threads. The deformation creates friction that resists rotation in both directions. Trojan Special Fasteners can manufacture left-hand threaded all-metal prevailing torque nuts to BS, ISO, or DIN specifications. Left-hand threads are common in rotating machinery to prevent self-loosening due to rotation direction. Clearly specify LH or LHT on drawings.

14. What happens if I use a property class 10 nut on a property class 8.8 bolt?

The harder nut may damage the softer bolt threads, potentially acting like a thread-cutting die. This destroys the bolt threads and eliminates proper clamping force. Always use nuts and bolts with compatible property classes per BS EN ISO 898-1 and 898-2—typically the bolt property class should be equal to or higher than the nut property class. For example, use property class 8 nuts with 8.8 bolts, or property class 10 nuts with 10.9 or 12.9 bolts.

15. Why can't I install all-metal prevailing torque nuts on long threaded sections?

Extended travel along threads creates cumulative wear on the nut's deformed threads and can also damage the bolt threads. The friction generated over long distances may also generate excessive heat. Install these nuts toward the end of the threaded portion where possible, ideally within 6-10 thread pitches of the end.

16. What is the difference between Style 1 and Style 2 all-metal prevailing torque nuts?

Style 1 nuts have a full hexagonal height and are thicker, whilst Style 2 nuts are thinner with a reduced height. Style 1 generally provides more thread engagement and higher prevailing torque values. The choice depends on space constraints and required performance. ISO 7719 covers Style 1; ISO 7042 and ISO 7720 cover Style 2.

17. Can all-metal prevailing torque nuts cause galling?

Yes, particularly in stainless steel or when used with tight thread tolerances (Class 3). The increased friction from the deformed threads combined with material properties can cause galling (cold welding). Mitigation strategies include using Class 2 threads, applying appropriate lubricants (never anti-seize on stainless), or specifying PTFE-coated nuts.

18. How do you test prevailing torque?

Per ISO 2320, the nut is threaded onto a calibrated mandrel (test bolt) without exceeding the proof load. The torque required to rotate the nut through a specific thread engagement range is measured using a torque-measuring device. The measured value must fall within the minimum and maximum prevailing torque limits defined in the relevant standard.

19. What is "first ON" versus "first OFF" prevailing torque?

"First ON" is the torque required when threading a new nut onto a bolt for the first time. "First OFF" is the torque required to remove it after initial installation. Subsequent installation/removal cycles show progressively lower values. Standards typically specify minimum first ON prevailing torque values.

20. Can all-metal prevailing torque nuts be used in dynamic or fatigue-loaded applications?

Yes, provided the joint is properly designed per VDI 2230 or Eurocode 3 (BS EN 1993). The prevailing torque prevents loosening under vibration, which is excellent for dynamic applications. However, ensure adequate bolt preload is maintained and that the bolt itself is designed for fatigue loading per BS 7608 or Eurocode 3 (appropriate stress concentration factors, proper property class). The nut prevents loosening but doesn't improve the bolt's fatigue life. For rotating machinery under Machinery Directive 2006/42/EC, proper fastener selection is critical.

Material and Coating Questions

21. Which material grade should I specify for my application?

Common grades include:

- Property Class 5 or 8: General industrial applications, non-critical assemblies

- Property Class 10: High-stress applications, heavy machinery, automotive safety-critical components

- Property Class 12: Extreme loading, aerospace, critical assemblies per AS/EN 9100

- Stainless A2: Corrosive environments, food equipment per EU 1935/2004

- Stainless A4: Marine, chemical processing, offshore per NORSOK standards

- Brass CZ121: Electrical applications, intrinsically safe per ATEX Directive 2014/34/EU

Consult with Trojan's technical team to select the optimal material for your specific requirements.

22. What finish provides the best corrosion resistance?

For mild UK environments (urban, rural), bright zinc plating to ISO 2081 (Fe/Zn 8μm) provides adequate protection with approximately 200-300 hours to red rust per ISO 9227 salt spray testing. For harsh environments (coastal, industrial), specify:

- Hot-dip galvanising to EN ISO 1461 (minimum 45μm) - 1,000+ hours salt spray resistance

- 316 stainless steel (A4) to EN 10088 - inherent corrosion resistance

- Zinc-nickel alloy plating (RoHS compliant) - 720+ hours salt spray resistance

- Delta-Tone® or Geomet® coating - automotive OEM approved, 1,000+ hours resistance

For North Sea offshore applications, specify 316L stainless as per NORSOK M-650. The finish must also be compatible with your assembly process as some coatings affect torque values per VDI 2230.

23. Can all-metal prevailing torque nuts be hot-dip galvanised to EN ISO 1461?

Yes, but the galvanising process (450°C molten zinc bath) often leaves zinc deposits in the threads, reducing the tolerance class and potentially interfering with the prevailing torque mechanism. Trojan Special Fasteners offers retapping services to restore thread forms to ISO 965-1 tolerances after galvanising, ensuring proper fit and function. Many customers send us their nuts for post-galvanising thread restoration. This is particularly important for tolerance class 6H threads. We can also oversize tap before galvanising to account for zinc coating thickness.

24. Why is brass used for all-metal prevailing torque nuts?

Brass (typically CZ121/CW614N per EN 12164) provides excellent electrical conductivity, corrosion resistance, and is non-sparking. It's specified in electrical switchgear, intrinsically safe equipment per ATEX Directive 2014/34/EU, and applications where spark generation could ignite flammable atmospheres (Zone 1 and Zone 2 hazardous areas). Brass is softer than steel, so prevailing torque values and reusability differ from steel nuts. Common in British electrical engineering heritage and modern renewable energy installations.

25. Can you supply all-metal prevailing torque nuts in other materials?

Yes, Trojan Special Fasteners can manufacture in phosphor bronze, aluminium bronze, and other alloys subject to material availability. These are typically for aerospace, nuclear, petrochemical, or marine applications with extreme requirements.

Subject to material availability and minimum order quantities. EN 10204 3.1 certificates provided as standard.

26. What is your minimum order quantity?

Trojan Special Fasteners has no strict minimum order quantity. We manufacture from single prototype nuts through to production volumes of thousands. Small batch manufacturing is our speciality, providing flexibility that large distributors cannot match.

27. How long is the lead time for custom all-metal prevailing torque nuts?

Typical lead times range from 1-2 weeks depending on material availability, complexity, and quantity. Urgent requirements can often be expedited. Contact us with your specification, and we'll provide a realistic delivery schedule.

28. Can you work from a sample rather than a drawing?

Yes, send us your sample nut and we'll reverse-engineer it, creating a technical drawing for your approval before manufacturing. This is common when customers have legacy parts without documentation.

29. Do you offer free-issue machining services?

Yes, we can work with customer-supplied material or blanks. Send us your round bar or pre-formed nuts, and we'll perform operations including tapping, polygon turning (hexagon from round), slotting, and deformation. Visit our services page for full details.

30. Can you match proprietary designs like Stover, Philidas, or Aerotight nuts?

We do not manufacture trademarked products, but we can produce functionally equivalent nuts based on your drawings that utilise similar locking principles. Provide dimensional specifications and performance requirements, and we'll manufacture to your exact needs.

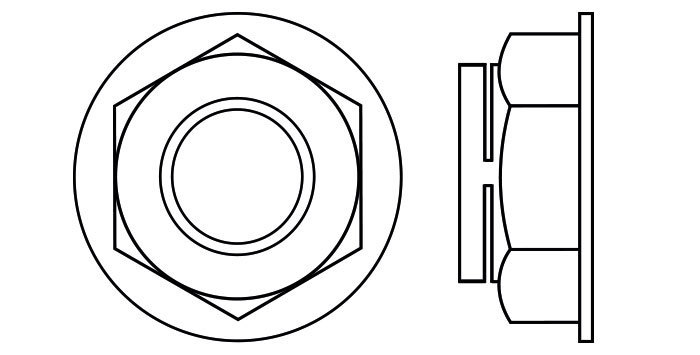

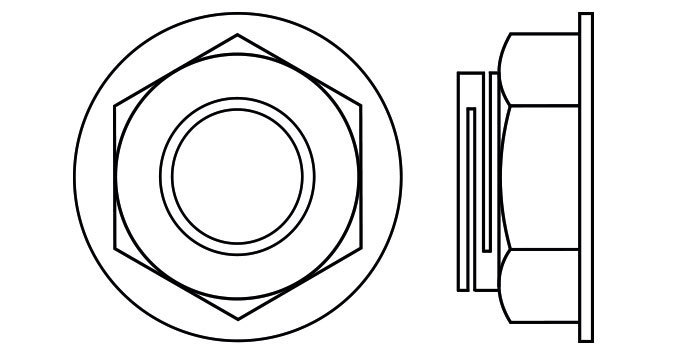

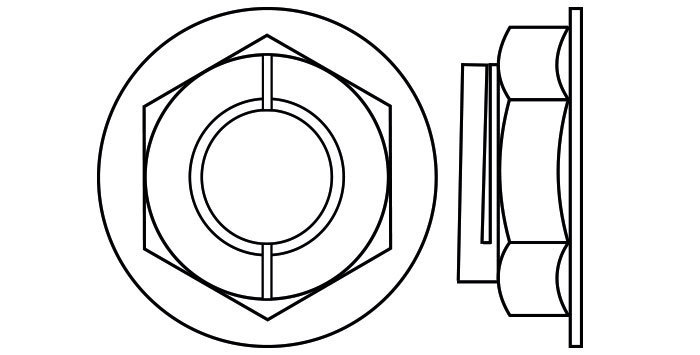

31. Can you manufacture flange-style all-metal prevailing torque nuts?

Yes, we produce hexagon flange prevailing torque nuts to ISO 12126, DIN 6927, and ASME B18.16.3M standards. The integrated flange provides greater bearing area and distributes load over a larger surface, eliminating the need for separate washers in many applications.

32. Do you provide technical support for specifying the right nut?

Absolutely. Our experienced team can advise on material selection, finish options, thread tolerances, and installation procedures. Contact us at 0121 789 8586 or trojan.fasteners@gmail.com with your application details.

33. Can you manufacture square all-metal prevailing torque nuts?

Yes, we can machine square nuts from round or hexagonal stock using our polygon turning capabilities. Square nuts are sometimes specified where wrench access is limited or for specific aesthetic requirements.

34. What tolerances can you achieve?

We routinely work to ISO 2768-m medium tolerances. Tighter tolerances are achievable when specified. Thread tolerances typically conform to Class 6H for metric or Class 2B for unified threads unless otherwise specified.

35. Can you provide material certifications and test certificates?

Yes, we can supply:

- Material certificates to EN 10204 3.1 with full traceability to steel mill

- Dimensional inspection reports per BS EN ISO 898-2

- Prevailing torque test certificates per BS EN ISO 2320:2015

- Hardness test certificates (Rockwell or Vickers per EN ISO 6507)

- Proof load test certificates per BS EN ISO 898-2

- REACH compliance declarations per EC 1907/2006

- RoHS declarations per Directive 2011/65/EU

- Conflict minerals declarations per EU Conflict Minerals Regulation 2017/821

- CBAM values for your export requirements

We just ask that you advise your documentary requirements at the quotation stage.

Application-Specific Questions

36. Are all-metal prevailing torque nuts suitable for automotive exhaust systems?

Excellent choice. Exhaust manifolds, catalytic converters, and exhaust pipes experience high temperatures (often exceeding 400°C) where nylon insert nuts would fail. Grade 8 or 10 steel nuts with appropriate finish provide reliable performance. Stainless steel 304 or 316 offers superior longevity in corrosive exhaust environments.

37. Can I use all-metal prevailing torque nuts in aluminium assemblies?

Yes, but select materials carefully to avoid galvanic corrosion. For aluminium applications, consider stainless steel 316 nuts with PTFE coating, or manufacture the nuts in aluminium alloy (though aluminium provides much lower prevailing torque values). Always use proper washers to distribute load on softer aluminium.

38. Are these nuts suitable for railway applications?

Yes, railway bogies, brake assemblies, and structural connections frequently specify all-metal prevailing torque nuts due to extreme vibration. They're approved in many railway standards worldwide. Trojan supplies the rail industry.

39. Can all-metal prevailing torque nuts be used in aircraft?

They're widely used in general aviation and aerospace applications, though specific approvals depend on the aircraft type and component. For certified aircraft, ensure your specification includes the appropriate AS, NAS, or MS standard numbers and that material certifications meet aerospace requirements.

40. Are these nuts suitable for hydraulic systems?

Yes, particularly in high-temperature hydraulic systems or where vibration is significant. Ensure the material is compatible with your hydraulic fluid. For applications involving mineral oil, synthetic hydraulics, or phosphate ester fluids at elevated temperatures, all-metal prevailing torque nuts outperform nylon insert alternatives.

41. Can I use all-metal prevailing torque nuts on playground or outdoor equipment?

Yes, especially for high-wear pivot points and structural connections exposed to weather. Specify hot-dip galvanised or 316 stainless steel for longevity. The nuts prevent loosening due to vibration from use whilst maintaining child safety. Regularly inspect per maintenance schedules, as outdoor UV and moisture can affect steel fasteners over decades.

42. Are these nuts appropriate for conveyor systems?

Ideal for conveyor drives, roller assemblies, and mounting brackets where vibration is constant. The elevated temperatures from motor housings and friction also favour all-metal designs. Regular maintenance still applies-check for wear and replace nuts that show reduced prevailing torque.

Standards and Compliance Questions

43. What does "property class" mean for all-metal prevailing torque nuts?

Property class indicates the material's mechanical properties-primarily tensile strength and hardness. Common unified classes include:

- Class 5: Lower strength, suitable for general applications

- Class 8: Medium-high strength for most industrial uses

- Class 10: High strength for demanding applications

The property class must be compatible with the mating bolt to prevent thread damage.

44. Do BSW and BSF threads have prevailing torque standards?

No, ISO 898 and IFI 100/107 only cover metric and unified threads. For British Standard Whitworth (BSW) and British Standard Fine (BSF) threads, prevailing torque values must be agreed between customer and supplier based on testing or engineering calculation.

45. What is the difference between ISO and DIN standards?

ISO standards are international, whilst DIN standards are German national standards. Many DIN standards have been superseded by equivalent ISO standards (e.g., DIN 980 → ISO 7042), though DIN references persist on legacy drawings. Trojan manufactures to either specification.

46. Are your nuts RoHS compliant?

Yes, we offer RoHS-compliant finishes. Traditional cadmium plating is now restricted under RoHS and REACH regulations so this is no longer offered. We can provide alternative compliant finishes including zinc-nickel alloy plating, which offers similar corrosion protection without hazardous substances.

47. Can you provide REACH and conflict minerals declarations?

Yes, we can supply REACH declarations and conflict minerals (Dodd-Frank) statements when requested at quotation stage. This is increasingly required for export to the EU and USA.

48. What is ASTM A563 and which grades are suitable for prevailing torque applications?

ASTM A563 is the standard specification for carbon and alloy steel nuts for structural bolting. Grades A, C, and DH are commonly manufactured as prevailing torque lock nuts (typically Tri-Lok or similar styles). Grade DH provides the highest strength (175 ksi proof load) but has limited availability in sizes ¾" and larger, where ASTM A194 Grade 2H is often substituted. Grade C is popular in automotive applications and provides good high-temperature performance up to 450°F.

49. What is the difference between ASTM A563 Grade DH and ASTM A194 Grade 2H nuts?

Both are high-strength carbon steel nuts with similar mechanical properties (175 ksi proof load for Grade 2H, comparable for Grade DH). ASTM A194 Grade 2H is designed specifically for high-temperature and high-pressure service (boiler and pressure vessel applications), whilst A563 Grade DH is for structural bolting. In practice, A194 Grade 2H nuts are frequently substituted for A563 Grade DH in sizes ¾" and larger due to better availability. Both can be manufactured as prevailing torque lock nuts.

50. What are ASME B18.16.6 grades A, B, C, F, and G?

ASME B18.16.6 covers prevailing torque locknuts in both nylon insert and all-metal configurations. For all-metal prevailing torque lock nuts specifically, the standard defines five grades (inch series):

- Grade A: Lower strength, general purpose

- Grade B: Medium strength (equivalent to SAE Grade 5)

- Grade C: High strength (equivalent to SAE Grade 8), most common automotive grade

- Grade F: Corrosion-resistant (300 series stainless steel)

- Grade G: High-strength corrosion-resistant (higher strength stainless)

This standard superseded IFI 100/107, though the older designation is still frequently referenced. Note that ASME B18.16.6 also covers nylon insert grades (N2, N5, N8), which are detailed on our nylon insert nuts page.

51. What is the difference between BS 4929-1 and BS 4929-2?

BS 4929-1 covers metric series prevailing torque hexagon nuts, whilst BS 4929-2 covers unified (inch) series. Both standards specify dimensions, mechanical properties, performance requirements, and temperature ranges. Importantly, both standards cover nuts with either metallic (all-metal deformation) or non-metallic (nylon insert) locking elements. When specifying to BS 4929, clarify whether you require all-metal or nylon insert type. BS 4929-2 covers sizes from 0.164" to 1½", whilst BS 4929-1 covers metric equivalents.

52. Are there specific standards for aerospace all-metal prevailing torque nuts?

Yes, SAE AS1371 specifies self-locking all-metal prevailing torque nuts made of corrosion-resistant steel for aerospace applications, rated for use up to 800°F (427°C) with UNJ thread form. Additionally, various NAS (National Aerospace Standard) and MS/NASM (Military Standard) specifications cover precision aerospace fasteners. These aerospace nuts require full material certification and traceability per AS9100 quality management systems.

53. What is SAE J995 and when does it apply?

SAE J995 specifies mechanical and material requirements for three grades of steel nuts suitable for automotive and related engineering applications, sizes ¼" to 1½". Whilst primarily covering standard nuts, it's referenced when specifying automotive-grade prevailing torque lock nuts. For wheel nuts specifically, SAE J2283 provides comprehensive requirements including prevailing torque specifications for M10, M12, M14, and imperial sizes.

54. What is JIS B 1056 and when is it required?

JIS B 1056 is the Japanese Industrial Standard specifying functional properties for prevailing torque steel nuts, essentially Japan's equivalent to ISO 2320. It's required when supplying to Japanese manufacturers or when products are destined for the Japanese market. JIS B 1199-4 specifically covers all-metal hexagon flange prevailing torque nuts. Japanese automotive suppliers often also reference JASO F106 for testing procedures.

55. Can you manufacture to obsolete or superseded standards?

Yes, many legacy designs reference superseded standards such as DIN 980 (now ISO 7042), the original IFI 100/107 (now ASME B18.16.6), or older MS specifications (now NASM). We can manufacture to the dimensional requirements of these older standards when specified on customer drawings, ensuring compatibility with existing assemblies whilst applying current material and testing requirements where appropriate.

56. Do different standards have different prevailing torque value ranges?

Yes, prevailing torque values vary by standard, size, thread pitch, material grade, and deformation type. For example, ISO 7042 M10 class 10 nuts typically require 3-15 Nm first-ON prevailing torque, whilst ASME B18.16.6 Grade C ⅜"-16 nuts require different values in lb-in. Testing must be conducted per the relevant standard (ISO 2320, JASO F106, or per ASME B18.16.6 Appendix) using calibrated mandrels and equipment. We can provide test certificates confirming compliance.

57. What is ISO 10513 and how does it differ from ISO 7042?

ISO 10513 specifies all-metal hexagon high nuts (increased height) with fine pitch thread in property classes 8, 10, and 12. ISO 7042 covers standard height nuts with coarse pitch thread. High nuts provide more thread engagement, reducing the risk of thread stripping with fine pitch threads. ISO 10513 nuts are used where space permits and higher clamping force is required with fine-pitch threads, common in precision machinery and instrumentation.

58. Can you supply nuts certified to multiple standards simultaneously?

Yes, many designs comply with multiple equivalent standards. For example, a metric M12 all-metal prevailing torque nut might simultaneously meet ISO 7042, DIN 980, EN 1664, BS EN ISO 7042, and other harmonised requirements, as these standards share common dimensional specifications. However, material certificates and markings must clearly identify which standard(s) the nuts are certified against. Some standards have subtle differences in tolerances or test requirements, so we verify compliance before dual-certification.

59. What is the difference between BS, BS EN ISO, and BS ISO standards?

These designations reflect how British Standards adopt international standards:

- BS standards (e.g., BS 4929) are original British Standards developed by BSI

- BS EN ISO standards (e.g., BS EN ISO 7042, BS EN ISO 7719) are British adoptions of European harmonised standards based on ISO standards - these are identical to the ISO standard and recognised across Europe

- BS ISO standards (e.g., BS ISO 7720) are British adoptions of ISO standards without European harmonisation

All three carry equal weight for UK compliance. BS EN ISO standards are often preferred for European export as they satisfy both UK and EU requirements simultaneously.

60. What is the difference between NF, NF EN, and NF EN ISO standards?

These designations reflect how French standards (AFNOR) adopt international standards:

- NF standards (e.g., NF E25-410, NF E25-411) are original French National Standards developed by AFNOR

- NF EN standards (e.g., NF EN 1664, NF EN 1667) are French adoptions of European harmonised standards - recognised across Europe

- NF EN ISO standards (e.g., NF EN ISO 7042) are French adoptions of European harmonised ISO standards - offering triple compliance (French, European, International)

For European and French markets, specifying NF EN or NF EN ISO standards ensures compliance across multiple jurisdictions. The NF E25 series (408-414, 420-422, 507) are specifically French standards commonly used in French aerospace, automotive, and industrial applications.

61. Why are NF (French) standards important for fastener manufacturers?

France is a major European manufacturing hub, particularly in aerospace (Airbus, Dassault, Safran), automotive (Renault, Peugeot, Citroën), and rail (Alstom). French manufacturers often specify NF standards, especially the NF E25 series for prevailing torque nuts. The NF E25-411 (with slots) and NF E25-414 (with flange) are particularly common in French aerospace and defence applications. UK manufacturers supplying to French OEMs or the French market must be able to certify to NF standards. Additionally, many former French colonies and French-speaking countries specify NF standards in their procurement requirements.

Troubleshooting and Problem-Solving

62. Why is my all-metal prevailing torque nut difficult to start on the thread?

Possible causes include:

- Damaged threads on nut or bolt (burrs, cross-threading)

- Incorrect thread class (interference fit)

- Contamination (paint, dirt, corrosion)

- Excessive prevailing torque due to over-deformation

- Wrong nut orientation (cone-first installation)

Always start nuts by hand to verify correct engagement before applying power tools.

60. Why is my all-metal prevailing torque nut difficult to start on the thread?

Possible causes include:

- Damaged threads on nut or bolt (burrs, cross-threading)

- Incorrect thread class (interference fit)

- Contamination (paint, dirt, corrosion)

- Excessive prevailing torque due to over-deformation

- Wrong nut orientation (cone-first installation)

Always start nuts by hand to verify correct engagement before applying power tools.

61. The prevailing torque seems too low—what could be wrong?

Potential issues:

- Nut has been reused too many times

- Deformation was insufficient during manufacturing (quality issue)

- Bolt threads are worn or damaged

- Wrong thread tolerance combination

- Contamination reducing friction

Measure the actual prevailing torque per ISO 2320 using a calibrated mandrel. If below specification, replace the nut.

62. Can I use an impact wrench to install all-metal prevailing torque nuts?

Not recommended. The prevailing torque requires controlled tightening to achieve correct bolt tension. Impact wrenches can over-torque the assembly or damage the nut's locking feature. Use a calibrated torque wrench set to the combined value (clamping torque + prevailing torque).

63. The nut seems to be cutting the bolt threads—why?

The nut material grade is likely harder than the bolt. Always use a bolt of equal or higher strength grade than the nut. For example, a Grade 10 all-metal lock nut requires a Grade 10.9 or higher bolt. Mixing incompatible grades causes thread damage and assembly failure.

64. How do I prevent galling in stainless steel all-metal prevailing torque nuts?

Strategies to prevent galling:

- Use Class 2 threads (looser tolerance)

- Apply appropriate lubricant (NOT anti-seize on stainless—it can cause hydrogen embrittlement)

- Use PTFE-coated nuts

- Install slowly with controlled torque

- Consider mixing materials (e.g., 316 nut with Monel bolt)

- Ensure threads are clean and free from contamination

65. What are the advantages of flange-style all-metal prevailing torque nuts?

Flange nuts (per ISO 12126, DIN 6927, ASME B18.16M) combine the prevailing torque locking feature with an integrated flange (washer). Benefits include: larger bearing surface area distributing load over a greater surface (reducing substrate stress), elimination of separate washers (faster assembly, lower parts count), improved resistance to embedment in softer materials, and reduced risk of washer loss during service. They're ideal for sheet metal assemblies, plastic components, and applications requiring vibration resistance with load distribution.

65. Can all-metal prevailing torque nuts be used with fine-pitch threads?

Yes, but special consideration is required. Fine-pitch threads have less thread height, increasing the risk of stripping. ISO 10513 specifically addresses this by specifying high nuts (increased nut height) for fine-pitch all-metal prevailing torque applications. The additional height provides more thread engagement, compensating for the reduced thread strength of fine pitches. Always verify that thread engagement meets the minimum requirement (typically 1× nominal diameter for steel-to-steel assemblies).

66. What is the difference between automation lock nuts and tri-lock nuts?

Automation lock nuts (also called Stover nuts, DIN 980V, or ISO 7042 nuts) typically feature a conical section deformed at two points creating an elliptical thread distortion. Tri-lock nuts are deformed at three points (120° apart), creating a more uniformly distributed locking action. Both function on the same principle—elliptical thread deformation creating prevailing torque—but tri-lock designs can provide more consistent torque values around the circumference. Performance differences are generally minor; selection often depends on manufacturer capability and customer preference.

67. How does temperature affect prevailing torque?

Prevailing torque typically decreases at elevated temperatures due to thermal expansion reducing interference fit, and softening of materials reducing elastic recovery force. Conversely, very low temperatures can increase prevailing torque due to thermal contraction and increased material hardness. For critical applications across temperature ranges, specify testing per ISO 2320 or JASO F106 at application temperature extremes. All-metal nuts maintain locking function throughout their temperature range (unlike nylon inserts which melt), but numerical torque values will vary with temperature.

68. Can all-metal prevailing torque nuts be used in marine saltwater environments?

Yes, with appropriate material selection. Specify 316 stainless steel (superior corrosion resistance to 304) or consider duplex stainless, Monel, or other marine-grade alloys for the harshest environments. Avoid carbon steel even with heavy galvanising for immersed or splash-zone applications. For above-waterline marine use, hot-dip galvanised carbon steel or 304 stainless may suffice. Always consider galvanic compatibility with mating bolts and surrounding hardware.

69. What is the difference between "proof load" and "prevailing torque"?

Proof load is the axial tensile force the nut must withstand without thread stripping or permanent deformation (specified in ISO 898-2, ASTM A563, ASME B18.16.6). It ensures the nut can develop full bolt clamping force. Prevailing torque is the rotational resistance created by the locking feature, measured during installation/removal (specified in ISO 2320, JASO F106). Both are critical: proof load ensures structural strength, whilst prevailing torque prevents loosening. A nut can have high proof load but inadequate prevailing torque, or vice versa—both must meet specification.

70. How do I calculate the total installation torque for an all-metal prevailing torque nut?

Total installation torque = Desired clamping torque + Prevailing torque + Friction losses

The prevailing torque value is found in the relevant standard (ISO 7042, ASME B18.16.6, etc.) based on size and grade. Add this to the bolt clamping torque needed to achieve required preload. Note that standard torque charts do NOT account for prevailing torque. For example: if a ⅜"-16 Grade C bolt requires 25 ft-lb to achieve proper preload, and the Grade C prevailing torque nut adds 6 ft-lb prevailing torque, apply approximately 31 ft-lb total. Always verify with torque-tension testing for critical applications.

71. Can all-metal prevailing torque nuts be used in radiation environments?

Ye, all-metal nuts are excellent for nuclear and radiation environments where organic materials (nylon, rubber) rapidly degrade under ionizing radiation. Specify appropriate material grades resistant to radiation-induced embrittlement. Stainless steels 304 and 316 perform well in moderate radiation. For high-flux environments (reactor internals, spent fuel handling), consider Inconel, Nitronic, or other radiation-hardened alloys. All-metal prevailing torque eliminates the concern of polymer degradation that plagues nylon insert nuts in these applications.

72. What is the shelf life of all-metal prevailing torque nuts?

Essentially unlimited if stored properly. Unlike nylon insert nuts (which can degrade over 5-10 years), all-metal prevailing torque nuts are entirely metallic with no polymer or elastomer components to age. Store in a dry environment to prevent corrosion, particularly important for zinc-plated or uncoated carbon steel nuts. Stainless steel nuts are essentially unaffected by storage time. Inspect for surface corrosion before use if stored for extended periods (>5 years) in uncontrolled environments.

73. Can you manufacture left-hand threaded all-metal prevailing torque nuts?

Yes, the prevailing torque mechanism works identically on left-hand threads (LH or LHT designation). Left-hand nuts are specified when rotation direction would tend to unscrew standard right-hand fasteners (rotating shafts, bicycle pedals, certain machinery). The deformation creates resistance to rotation in both directions, so left-hand prevailing torque nuts function exactly like right-hand versions. Provide clear LH specification on drawings to avoid errors.

74. What quality control testing do you perform on all-metal prevailing torque nuts?

Our quality control includes dimensional inspection (thread gauges, callipers, height, across-flats), hardness testing (Rockwell or Vickers per material grade requirements), proof load testing (per ISO 898-2 or relevant standard), and prevailing torque testing (per ISO 2320 or JASO F106) using calibrated mandrels and torque measuring equipment. Visual inspection checks for surface defects, proper deformation, and correct markings. For critical applications, we can provide 100% inspection, material certifications (EN 10204 3.1), and batch traceability. Statistical process control (SPC) ensures consistent quality across production runs.

Contact Trojan Special Fasteners for Your All-Metal Prevailing Torque Nut Requirements

Whether you need standard DIN 980 nuts in volume or bespoke all-metal prevailing torque nuts for a specialised application, Trojan Special Fasteners has the expertise and manufacturing flexibility to deliver.

Get in touch today:

- Telephone: 0121 789 8586

- Email: trojan.fasteners@gmail.com

- Address: 18 Fortnum Close, Tile Cross, Birmingham, B33 0LG

We welcome enquiries with drawings, samples, or specifications. Our team will respond promptly with competitive quotations and realistic lead times.

Related Products and Services

Explore our other precision fastener manufacturing capabilities:

- Nylon Insert Nuts - For lower temperature applications

- Castle Nuts and Slotted Nuts - For split pin locking

- Hexagon Full Nuts - Standard heavy duty nuts

- Thin Nuts - For space-constrained applications

- Precision Polygon Turning Services - Convert round to hexagon/square

- Thread Tapping and Modification - Custom thread forms

- Technical Resources - Standards, specifications, and guides

- Blog - Latest fastener industry insights