AS 1252

AS 1252:1996

High strength steel nuts for structural engineering.

Nuts in parentheses are non-preferred sizes.

Please note - we will not manufacture nuts with circumferential indentations at three points on these kinds of nuts as specified in clause 1.5.2 of this standard.

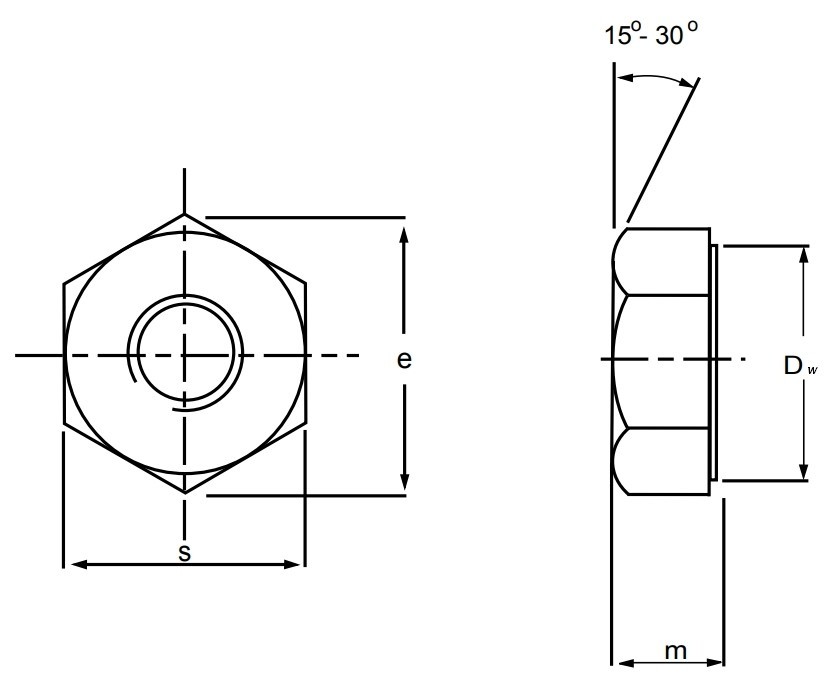

| Thread | Pitch | Across Flat (s) | Across Corner (e) | Nut Thickness (m) | Squareness Tolerance (max) | Symmetry Tolerance (max) | Washer Face Dia (Dw) (min) | Washer Face Thickness (c) | Countersink Diameter (da) |

|---|---|---|---|---|---|---|---|---|---|

| M16 | 2.0 | 27.0-26.16 | 31.20-29.56 | 17.1-16.4 | 0.76 | 1.04 | 24.90 | 0.8-0.4 | 17.3-16.0 |

| M20 | 2.5 | 34.0-33.00 | 39.26-37.29 | 20.7-19.4 | 0.90 | 1.24 | 31.40 | 0.8-0.4 | 21.6-20.0 |

| (M22) | 2.5 | 36.0-35.00 | 41.6-39.55 | 23.6-22.3 | 1.00 | 1.24 | 33.3 | 0.8-0.4 | 23.8-22.0 |

| M24 | 3.0 | 41.0-40.00 | 47.3-45.20 | 24.2-22.9 | 1.04 | 1.24 | 38.0 | 0.8-0.4 | 25.9-24.0 |

| (M27) | 3.0 | 46.0-45.00 | 53.1-50.85 | 27.6-26.3 | 1.28 | 1.24 | 42.8 | 0.8-0.4 | 29.2-27.0 |

| M30 | 3.5 | 49.0-57.7 | 57.7-55.37 | 30.7-29.1 | 1.40 | 1.24 | 46.5 | 0.8-0.4 | 32.4-30.0 |

| M36 | 4.0 | 60.0-58.80 | 69.3-66.44 | 36.6-35.0 | 1.68 | 1.48 | 55.9 | 0.8-0.4 | 38.9-36.0 |

| Proof Stress |

Hardness | |||||

|---|---|---|---|---|---|---|

| Vickers | Rockwell C | Rockwell B | ||||

| MPa | max | min | max | min | min | |

| Hot-dip Galvanised | 1165 | 353 | 260 | 36 | 24 | - |

| Non Galvanised | 1075 | 353 | 188 | 36 | - | 89 |