Dome & Cap Nuts

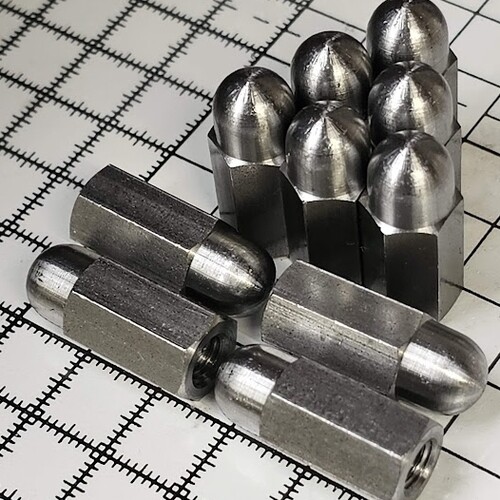

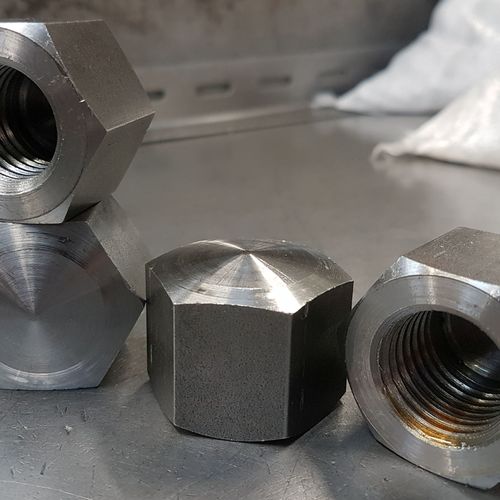

Trojan Special Fasteners Ltd can manufacture a number of dome and acorn cap nuts to standard, your drawing, sample or your specification. We can provide a head polishing service on some sizes too – just ask at quotation stage.

Predominantly these forms exist:

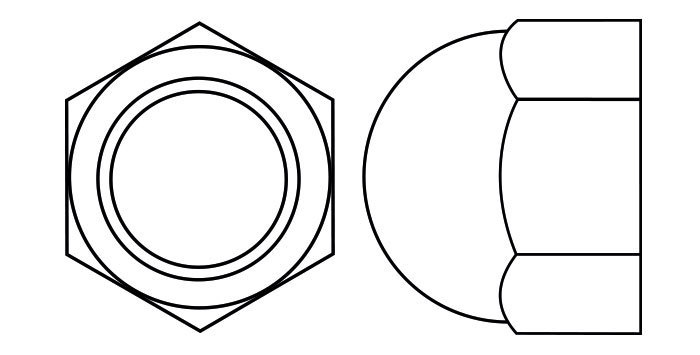

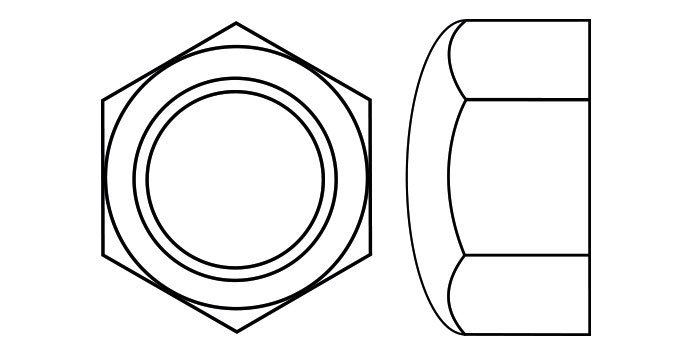

Short Cap Nuts

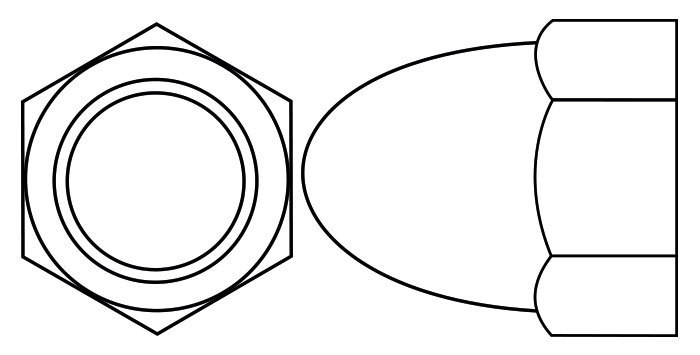

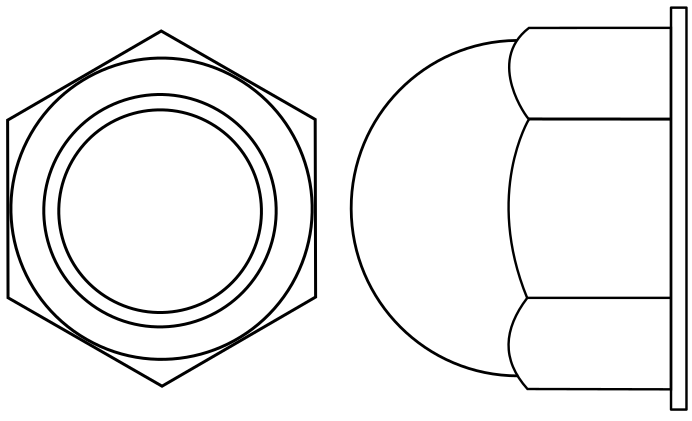

Low Dome Cap Nut

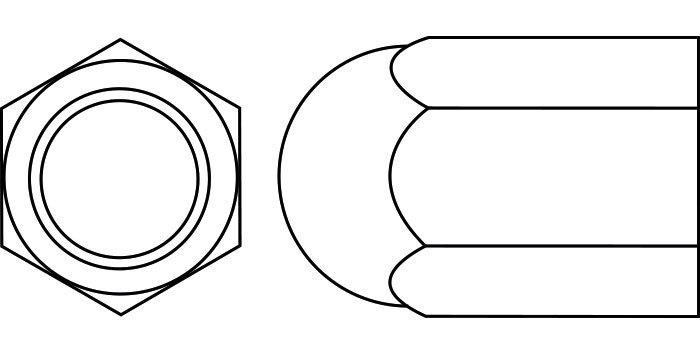

Custom Dome Nuts, Cap Nuts & Acorn Nuts - Bar Turned to Your Specification

Trojan Special Fasteners Ltd specialises in manufacturing high-precision dome and cap nuts (also known as acorn nuts, crown hex nuts, or blind nuts) from bar turning. We produce single-piece, solid construction dome nuts to DIN 1587, DIN 917, SAE J483, and other international specifications, with full customisation available to your drawings, samples, or technical requirements. All our dome nuts are machined from solid bar stock, ensuring superior strength and quality.

What Are Dome & Cap Nuts?

Dome nuts, cap nuts, or acorn nuts are specialist fasteners designed to provide a protective dome or cap end covering external threads. The domed head shields the threaded end of bolts, setscrews, or all-thread bars, preventing thread damage, improving safety, and delivering a superior aesthetic finish. These nuts are essential where exposed threads pose safety risks or where visual appearance matters.

Manufacturing Capabilities & Customisation

Size Ranges Available

- Metric: M3 to M52 (coarse and fine pitch threads)

- Imperial: 2BA to 2" (BSW, BSF threads)

- Unified: #8 to 2¼" (UNC, UNF threads)

- Custom sizes and non-preferred dimensions available

Precision Bar Turning

- High-precision CNC bar turning for single-piece construction

- All dome nuts machined from solid bar stock

- Consistent quality across all production runs

- Tolerances to ±0.01mm for critical dimensions

- Both preferred and non-preferred sizes manufactured

- Custom thread forms including metric, imperial, UNC, UNF, BSW, BSF, BSP, BA, and specialist threads

Design Options

- Standard dome profiles - high crown (DIN 1587) and low crown (DIN 917)

- Short cap nuts and elongated dome configurations

- Custom rotated designs and decorative finishes

- Flanged dome nuts with integral collars

- Extra-tall dome configurations for extended thread coverage

- Polished or mirror-finish domes for aesthetic applications

Thread Locking Features

- Prevailing torque deformation (side-crimped or top-deformed) - single-piece construction

- Custom torque specifications to your requirements

- Torque testing services available (provide female threaded part)

- All-metal construction for superior temperature resistance and durability

- Alternative to two-piece nylon insert nuts (DIN 986 type - which we do not manufacture)

- Re-usable with consistent locking performance

Surface Treatments & Finishes

- Head polishing service for aesthetic applications

- Zinc plating (clear, yellow, black)

- Hot-dip galvanising for corrosion resistance

- Nickel or chrome plating

- Passivation for stainless steel grades

- Self-colour, black oxide finishes

We can manufacture to the following specifications:

We can manufacture acorn, dome and cap nuts to the following specifications:

| Standard | Description |

|---|---|

| DIN 917 | Hexagon acorn nuts Hexagon cap nuts, low type - German standard for low-profile (short crown) cap nuts. Features a shallower dome profile compared to DIN 1587, ideal for space-constrained applications. Covers M4-M72 (non-preferred sizes in brackets). From M10 upwards, includes DIN 76-1 type D thread undercut. Available in steel grade 6 and stainless steel A2-70, A4-70. | Metric M4-M72 |

| DIN 986 | *WITHDRAWN WITHOUT REPLACEMENT Prevailing torque type hexagon domed cap nuts with non-metallic insert - Two-piece construction with nylon insert. Standard covered M4-M20 with product classes A and B. The nylon insert provides vibration resistance up to 121°C. Available in steel grades 5, 6, 8, 10 and stainless steel A2, A4. | NOT MANUFACTURED BY TROJAN* - We specialise in single-piece dome nuts machined from solid bar stock. DIN 986 requires two-piece assembly construction which is outside our manufacturing process. For vibration resistance, we offer single-piece prevailing torque dome nuts with mechanical deformation. |

| DIN 1587 | Hexagon acorn dome nuts |

| UNI 5721 | Domed cap nuts - Italian national standard specifically for dome/acorn nuts. Widely used in European automotive and industrial applications, particularly for wheels, axles, and visible fastening applications. Defines dimensions and tolerances for metric sizes. | Metric |

| SAE J483 | High and Low Crown (Blind, Acorn) Hex Nuts - American automotive standard defining dimensional specifications for both high-crown (tall) and low-crown (short) dome nuts. Primarily intended for automotive and ground-based motor vehicles and industrial equipment. Provides ornamental finish and thread protection. | Imperial & Unified |

| ANSI/ASME B18.2.2 | Square and Hex Nuts (Inch Series) - Includes dimensional specifications for cap nuts (acorn nuts) in imperial sizes. Covers standard hex nuts and variations including cap/dome configurations. Used widely in North American manufacturing. | Imperial #4-4" |

| JIS B 1183 | Hexagon domed cap nuts - Japanese Industrial Standard specifically for acorn/dome nuts. Detailed specifications for automotive, electronics, and industrial sectors. Covers both standard and fine pitch threads with specific mechanical property requirements. | Metric |

| GB/T 923 | Hexagon domed cap nuts - Chinese national standard for dome nuts. Used extensively across Chinese manufacturing, construction, and automotive sectors. Specifies dimensions, tolerances, and mechanical properties for metric dome nuts. | Metric |

Alternative to DIN 986 Two-Piece Nylon Insert Dome Nuts

Whilst we do not manufacture two-piece dome nuts with nylon inserts (DIN 986 type), we can provide superior single-piece alternatives machined from solid bar stock:

Our Single-Piece Prevailing Torque Dome Nuts:

- Mechanical deformation (side-crimped or top-deformed) for vibration resistance

- All-metal construction - no plastic inserts that can degrade over time

- Higher temperature resistance than nylon inserts (no 121°C limitation)

- Custom torque specifications available

- Torque testing services provided

- Fully re-usable with consistent locking performance

- Superior strength due to single-piece construction

- Available in all materials: carbon steel, stainless steel, brass, aluminium

If you have a specification requiring DIN 986 nylon insert dome nuts, please contact us to discuss single-piece all-metal alternatives that may provide superior performance for your application.

Material Specifications & Grades

Carbon Steel

- Materials: EN1A, EN1APb, EN3B, EN8, EN8D, EN16T, EN19T, AISI 1010, 1018, 1045

- Heat-treated to achieve required hardness

- Nut Grades: 4, 5, 6, 8, 10, 12 (Note: Grade 12 is maximum for nuts) - however typically dome and cap nuts are not graded because they're typically only used for decoration as opposed to providing any required torque.

- Finishes: Plain, black oxide, zinc-plated, hot-dip galvanised, zinc-flake.

Stainless Steel

- Grades: 303 (free-machining), 304 (A2), 316 (A4), 321

- Austenitic grades (304, 316) for maximum corrosion resistance

- Grade 303 for enhanced machinability on complex dome profiles

- Passivated or electropolished finishes available

- Marine-grade 316 for coastal and offshore environments

Brass & Copper Alloys

- Free-cutting brass (CW614N, CZ112, CZ121, CZ122)

- Naval brass for marine applications

- Excellent for decorative applications

- Natural, nickel-plated, or chrome-plated finishes

- Corrosion-resistant with attractive appearance

Aluminium Alloys

- Grades: 2011 (free-machining), 6061, 6082

- Lightweight dome nuts for weight-critical applications

- Anodised finishes in various colours available

- Good strength-to-weight ratio

- Ideal for automotive, aerospace, and electronic applications

Mechanical Properties by Grade

Carbon Steel Dome Nuts

- Grade 4: Min. proof stress 225 N/mm², hardness 95-205 HV

- Grade 5: Min. proof stress 310 N/mm², hardness 155-230 HV

- Grade 6: Min. proof stress 380 N/mm², hardness 180-250 HV

- Grade 8: Min. proof stress 600 N/mm², hardness 240-320 HV

- Grade 10: Min. proof stress 830 N/mm², hardness 290-360 HV

- Grade 12: Min. proof stress 1040 N/mm², hardness 310-380 HV

Stainless Steel Dome Nuts

- A2-50: Min. proof stress 210 N/mm² (304 grade, standard strength)

- A2-70: Min. proof stress 450 N/mm² (304 grade, high strength)

- A4-70: Min. proof stress 450 N/mm² (316 grade, marine applications)

- A4-80: Min. proof stress 600 N/mm² (316 grade, highest strength)

Applications & Industries

Automotive & Transportation

- Wheel assemblies and suspension components

- Engine bay finishing and aesthetic applications

- Interior trim and dashboard mounting hardware

- Motorcycle, bicycle, and specialist vehicle components

- Classic car restoration projects

Construction & Structural Engineering

- Handrails, balustrades, and safety barriers

- Architectural metalwork and façade systems

- Decorative structural connections

- Scaffolding and temporary works

- Roof and cladding fixings where appearance matters

Marine & Offshore

- Boat fittings and deck hardware

- Rigging and sailing equipment (316 stainless)

- Yacht joinery and interior fittings

- Coastal infrastructure and piers

- Marina installations

Electronics & Electrical

- Control panels and enclosures

- Electrical junction boxes and distribution boards

- Telecommunications equipment cabinets

- Server racks and data centre hardware

- Consumer electronics assembly

Furniture & Interior Design

- High-end furniture manufacturing

- Exhibition stands and retail displays

- Designer lighting installations

- Decorative fixtures and fittings

- Architectural ironmongery

Medical & Laboratory Equipment

- Laboratory furniture and fume cupboards

- Hospital beds and medical trolleys

- Equipment housings and enclosures

- Hygienic stainless steel applications

- Pharmaceutical manufacturing equipment

Food & Beverage Processing

- Food processing machinery (316 stainless)

- Commercial kitchen equipment

- Brewing and distilling equipment

- Dairy processing systems

- Packaging machinery

Technical Specifications

Thread Standards Available

- Metric: M3 to M52 (coarse and fine pitch)

- Imperial: 2BA to 2" (BSW, BSF threads)

- Unified: #8 to 2¼" (UNC, UNF threads)

- Specialist: BSP, BA, BSCy (Cycle), CEI threads

- Custom: Any thread form manufactured to specification

Dimensional Tolerances

- Thread tolerance: 6H (standard), tighter tolerances available

- Hexagon across flats (AF): ±0.1mm standard, ±0.05mm precision

- Dome height: ±0.2mm standard tolerance

- Overall length: ±0.5mm standard

- Turning diameter: ±0.05mm

Dome Profile Options

- High crown (tall): Extended dome height for maximum thread coverage

- Low crown (short): Compact profile for space-constrained applications

- Standard: Balanced height per DIN 1587

- Custom profiles: Any rotated design to your specification

- Flanged: Integral flange for increased bearing surface

Quality Assurance & Testing

Inspection Procedures

- First-off sample inspection to drawing specification

- In-process dimensional checks during production runs

- Final inspection using calibrated measuring equipment

- Thread gauge inspection (plug and ring gauges)

- Surface finish verification and visual inspection

Testing Services Available

- Torque testing with customer-supplied female threads

- Proof load testing to ISO 898-2 requirements

- Hardness testing (Rockwell, Vickers, Brinell)

- Salt spray testing (ASTM B117 neutral salt spray)

- Material certification and full traceability

Certifications & Compliance

- ISO 9001:2015 Quality Management System

- Material certificates (3.1 available on request)

- REACH and RoHS compliance for applicable materials

- Full traceability from raw material to finished product

- Batch identification and record retention

Frequently Asked Questions (FAQs)

What is the difference between a dome nut and a cap nut?

Dome nuts and cap nuts are essentially the same product. "Dome nut" refers to the rounded dome shape, whilst "cap nut" describes its function of capping the thread end. Both terms are used interchangeably, along with "acorn nut" (due to its acorn-like appearance) and "crown nut". They all describe a hexagon nut with a closed, domed end.

What are the advantages of using dome nuts over standard hex nuts?

Dome nuts provide several key benefits: (1) Safety - covering sharp thread ends prevents injuries and snagging hazards; (2) Aesthetics - providing a clean, finished appearance for visible applications in automotive, furniture, and architectural work; (3) Thread protection - shielding threads from damage, contamination, dirt, and corrosion; (4) Weather resistance - preventing moisture ingress into threaded assemblies.

Can you manufacture dome nuts with flanges or collars?

Yes, we regularly manufacture flanged dome nuts to customer specifications. The flange or collar provides increased bearing surface area, distributing load more effectively and potentially eliminating the need for separate washers. This is particularly popular for automotive and furniture applications. Simply provide your drawing or detailed specification.

What is a prevailing torque dome nut?

A prevailing torque dome nut resists loosening from vibration without requiring additional locking compounds or split pins. There are two main types: (1) *Two-piece with nylon insert (DIN 986 - withdrawn standard, not manufactured by Trojan) where a plastic insert creates friction, and (2) Single-piece with mechanical deformation* (our speciality) where the nut body is deformed through side-crimping or top-deformation to create the locking effect. Our single-piece all-metal prevailing torque dome nuts offer superior temperature resistance (no 121°C limitation), better long-term durability, and consistent re-usable performance. We can manufacture to your specific torque specification and provide torque testing services.

What sizes of dome nuts can you manufacture?

We manufacture dome nuts in the following size ranges: Metric M3 to M52, Imperial 2BA to 2", and Unified #8 to 2¼". Both preferred standard sizes and non-preferred custom sizes are available. We also produce non-standard thread pitches (fine pitch, extra-fine, or custom) and special thread forms to specification.

What is the difference between high-crown and low-crown dome nuts?

High-crown (tall) dome nuts, manufactured to DIN 1587, have a more pronounced dome profile with greater internal depth, providing more thread coverage and a more substantial appearance. This prevents the bolt from touching the dome cap, ideal for vibration-prone applications. Low-crown (short or standard) dome nuts, manufactured to DIN 917, have a shallower dome profile, suitable where space is limited or a more subtle finish is required. SAE J483 defines both types for automotive applications.

Can you polish dome nuts for decorative applications?

Yes, we offer head polishing services on dome nuts, creating a mirror-like finish ideal for architectural, automotive, furniture, and high-end decorative applications where appearance is paramount. Polishing is available on stainless steel, brass, and chrome-plated carbon steel. We can achieve various finishes from satin to high-polish mirror finish.

What materials are best for outdoor or marine applications?

For outdoor applications, hot-dip galvanised carbon steel or grade 304 (A2) stainless steel dome nuts are suitable. For marine and coastal environments, we recommend 316 (A4) marine-grade stainless steel dome nuts with passivation treatment. Grade 316 offers superior corrosion resistance to salt water and chloride environments. Naval brass is also suitable for some marine decorative applications.

How do I specify a custom dome nut?

Provide us with either: (1) a technical drawing with dimensions including thread size, hexagon AF size, dome height, overall height, and material/finish requirements; (2) a sample part for reverse engineering; or (3) a detailed written specification. Our technical team will review your requirements and provide a quotation with lead time. We can also offer design suggestions to improve manufacturability if needed.

What delivery times can you achieve?

Lead times vary based on quantity, complexity, and material availability. Standard metric sizes (M6-M16) in carbon steel or 303/304 stainless may be available from stock or within 1-2 weeks for small batches. Custom specifications typically require 3-4 weeks for production quantities, with expedited service available for urgent requirements. Contact us with your specific needs for accurate delivery schedules.

Can you manufacture DIN 986 nylon insert dome nuts?

No, we do not manufacture DIN 986 two-piece dome nuts with nylon inserts. As a precision bar turning manufacturer, we specialise in single-piece dome nuts machined from solid bar stock. However, we can offer superior all-metal alternatives: single-piece prevailing torque dome nuts with mechanical deformation (side-crimped or top-deformed) that provide vibration resistance without nylon inserts. These offer higher temperature resistance (no 121°C limitation), better durability, and consistent re-usable locking performance. If you have a DIN 986 requirement, contact us to discuss suitable single-piece alternatives.

Why Choose Trojan Special Fasteners for Dome & Cap Nuts?

Precision Manufacturing Excellence

- Over 50 years of specialist bar turning expertise

- State-of-the-art CNC machinery for consistent quality

- Skilled engineering team with extensive fastener knowledge

- Flexible manufacturing from prototypes to production runs

Customisation Without Compromise

- Bespoke specifications welcome - no job too small

- Rapid prototyping and sampling services

- Design support and technical consultation

- Reverse engineering from samples or existing parts

Quality You Can Trust

- ISO 9001:2015 certified quality management

- 100% inspection available on critical applications

- Full material traceability and certification

- Long-standing relationships with UK and international clients

Competitive & Transparent Pricing

- Direct manufacturer pricing - no middlemen

- Free quotations within 24-48 hours

- Value engineering suggestions to reduce costs

- Consistent quality at competitive prices

Request a Quotation

For dome nuts, cap nuts, or acorn nuts manufactured to your exact specification, contact Trojan Special Fasteners today. Whether you need standard DIN 1587 dome nuts, SAE J483 high-crown acorn nuts, prevailing torque variants, or fully custom specifications for demanding applications, our technical team is ready to assist.

Get in touch:

- Submit your technical drawings, samples, or specifications via our contact form

- Call our sales team for immediate technical assistance

- Request material recommendations for your specific application

- Ask about lead times, pricing, minimum order quantities, and volume discounts

We serve customers across the UK, Europe, and worldwide, delivering precision-engineered dome and cap nuts that meet the most demanding quality standards.

Related Products You May Be Interested In

- Standard Hexagon Nuts - Full hex nuts in all sizes, grades and materials

- Nyloc Nuts - Self-locking nuts with nylon inserts for vibration resistance

- Flange Nuts - Integrated flange for increased bearing area and load distribution

- Wing Nuts - Hand-tightenable nuts for tool-free adjustment and frequent assembly

- Castle Nuts - Castellated nuts for split pin or cotter pin locking

- Slotted Nuts - Slotted for cotter pin or wire locking applications

- Coupling Nuts - Extended length nuts for joining threaded rods and studs

- Custom Nuts - Any nut form manufactured to your specification and drawing