Connector Nuts

Connector Nuts | Coupling Nuts | Hex & Round Profiles | UK Manufacturer

Precision-Manufactured Connector Nuts, Coupling Nuts & Joining Nuts – Custom Sizes, Materials & Finishes

Trojan Special Fasteners Ltd manufactures high-quality connector nuts (also known as coupling nuts, joining nuts, extension nuts, long nuts, and studding connectors) to exact customer specifications. With over 30 years of experience, we supply connector nuts across the complete size range from M3 to M52 metric, 2BA to 2" imperial (BSW/BSF), and #8 to 2¼" unified threads (UNC/UNF/UNEF) in hex, round, square, and custom profiles.

What Are Connector Nuts?

Connector nuts are elongated, internally threaded fasteners designed to join two male threaded components such as threaded rods, studs, or bolts. They provide a mechanical coupling that can be easily assembled, disassembled, and adjusted, making them essential components across construction, manufacturing, rail transport, marine, electrical, and industrial applications.

Key Characteristics:

- Internally threaded at both ends for joining male threaded components

- Available in hex, round, double-flat, square, and custom external profiles

- Standard and custom lengths to suit application requirements

- Can feature identical threads or mixed thread types/sizes (reducing connectors)

- Manufactured from steel, stainless steel, brass, aluminium, and specialist alloys

- Surface treatments available for corrosion resistance and performance enhancement

Complete Size Range & Manufacturing Capabilities

*Metric Threads:* M3, M4, M5, M6, M7, M8, M9, M10, M11, M12, M13, M14, M15, M16, M17, M18, M20, M22, M24, M25, M26, M27, M28, M30, M32, M33, M34, M35, M36, M38, M39, M40, M42, M45, M48, M50, M52, M56 (coarse, fine, extra-fine, and hard-to-find pitches)

*Imperial & Unified Threads (BSW/BSF/Whitworth/UNC/UNF/UNEF):* 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 9/16", 5/8", 11/16", 3/4", 7/8", 1", 1-1/16", 1-1/8", 1-3/16", 1-1/4", 1-5/16", 1-3/8", 1-7/16", 1-1/2", 1-5/8", 1-3/4", 1-7/8", 2", 2-1/4", 2-1/2"

*BA Threads (British Association):* 2BA, 1BA, BA0 (for precision instruments and electronics)

Additional Thread Forms:

- BSPP (British Standard Pipe Parallel) for pipe connections

- BSPT (British Standard Pipe Tapered) for sealing applications

- Custom threads manufactured to drawing specifications

- Left-hand threads available in most sizes and pitches

- Oversize threads available in selected pitches/TPI

Connector Nut Profiles & External Geometries

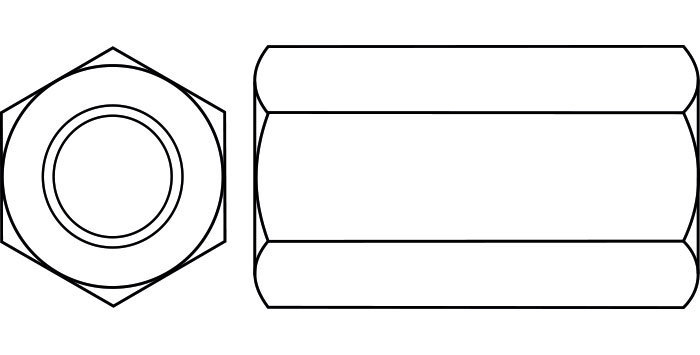

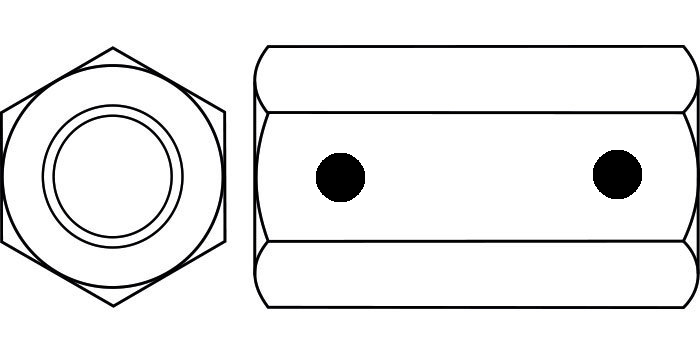

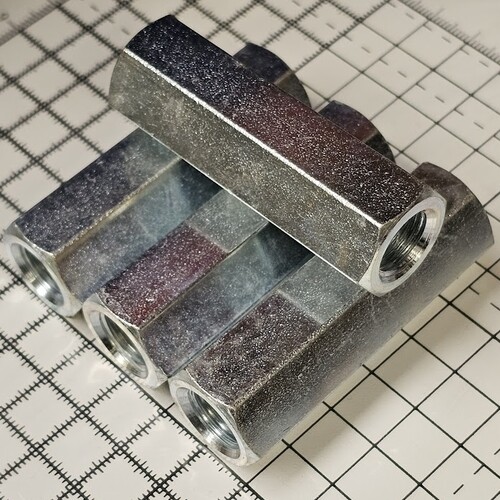

Hex Profile Connector Nuts

The most common profile, featuring six flats for easy installation with standard spanners and sockets. Hex connector nuts provide excellent grip and high torque transmission capability.

Standard Metric Hex Sizes (Across Flats)

All dimensions in mm

| THREAD SIZE | ACROSS FLATS | TYPICAL LENGTH (3D) | |

|---|---|---|---|

| M3 | 5.5 | 9 | |

| M4 | 7 | 12 | |

| M5 | 8 | 15 | |

| M6 | 10 | 18 | |

| M8 | 13 | 24 | |

| M10 | 17 | 30 | |

| M12 | 19 | 36 | |

| M14 | 22 | 42 | |

| M16 | 24 | 48 | |

| M18 | 27 | 54 | |

| M20 | 30 | 60 | |

| M22 | 32 | 66 | |

| M24 | 36 | 72 | |

| M27 | 41 | 81 | |

| M30 | 46 | 90 | |

| M36 | 55 | 108 | |

| M42 | 65 | 126 |

Custom across-flats dimensions available on request to suit specific spanner sizes or clearance requirements.

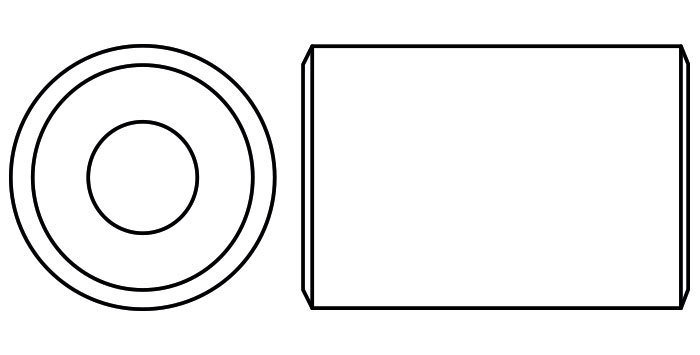

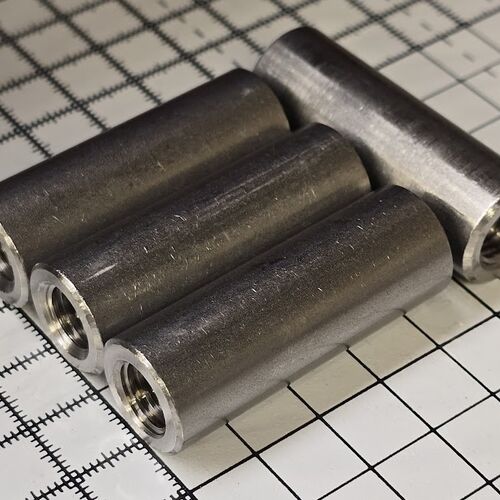

Round Profile Connector Nuts

Smooth cylindrical external surface ideal for applications requiring rotation, reduced weight, tight clearances, or aesthetic appearance. Round connectors are commonly used in decorative applications, precision alignment systems, and where spanners cannot be accommodated.

Square Profile Connector Nuts

Four-flat profile offering anti-rotation capability when fitted into square recesses or where hex profiles are too large. Square connector nuts are rare but available for specialist applications requiring specific torque characteristics.

Double-Flat Profile Connector Nuts

Feature two parallel flats on opposite sides of a round body, providing a compact spanner engagement point whilst maintaining a smaller overall diameter than hex profiles.

Custom Profile Options:

- Knurled external surfaces for hand-tightening or grip enhancement

- Serrated or toothed profiles for anti-rotation

- Precision ground outer diameters for press-fit or tight tolerance applications

- Flanged designs combining connector and washer functions

- Multi-diameter stepped profiles for complex assemblies

Thread Engagement & Length Calculations

Proper thread engagement is critical for connector nut performance and joint integrity.

Standard Engagement Guidelines:

Minimum Engagement per Side: 1.0 × nominal thread diameter

Standard Engagement: 1.0 to 1.5 × nominal thread diameter per side

Heavy-Duty Applications: 1.5 to 2.0 × nominal thread diameter per side

High-Stress or Fatigue Loading: 2.0 × nominal thread diameter per side minimum

Length Calculation Examples:

Example 1 – Standard M12 Connector Nut:

Thread diameter = 12 mm

Standard engagement = 1.0 × 12 = 12 mm per side

Minimum total length = 24 mm

Recommended standard length (3D) = 36 mm (provides 12mm engagement each side with 12mm central unthreaded section)

Example 2 – Heavy-Duty M20 Connector Nut:

Thread diameter = 20 mm

Heavy-duty engagement = 1.5 × 20 = 30 mm per side

Minimum total length = 60 mm

With central unthreaded section = 70-80 mm typical

Example 3 – ½" UNC Connector Nut (13 TPI):

Nominal diameter = 0.5" (12.7 mm)

Standard engagement = 0.5" per side

Minimum total length = 1.0"

Standard 3D length = 1.5"

Non-Standard Lengths:

We manufacture connector nuts in any length from ultra-short (1D = one diameter) to extra-long (depending on tooling). Custom lengths allow optimisation for specific applications where standard 3D connectors are unsuitable.

Typically they are 3 times the length of the inner diameter, but we can machine other sizes, just ask! We can manufacture these in a limited number of sizes with a square profile if needed – but these are extremely rare. We can make almost any combination of internal and external diameter or profile you’re looking for within available material specifications and finishes. At times customers ask these to be partially threaded on each end, sometimes with mixed thread sizes, pitches and a combination of left hand on one side and right hand on the other. Typically these are known as reducing coupling nuts.

Please be advised that the DIN 6334 standard that is often quoted is incorrect. This was a draft standard in 1943 but was never published as a standard and probably fell into disregard during the war. In various catalogues DIN 6334 is still used today by mistake or as a "sales argument". It must be noted that for this reason no official 'Grade' can be offered or marked for this fastener type and so whilst Trojan Special Fasteners Ltd manufactures these types of coupling nuts in metric thread form, we will always quote the material used.

In addition to standard preferred sizes, we also manufacture non preferred sizes and non standard or special thread and nut forms.

Trojan special fasteners can build additional features into fasteners, like collars, castellated, slotted portions and also cross drill and tap these:

Material Selection Guide

Carbon Steel Grades

EN1A (Bright Mild Steel): General-purpose applications, good machinability, economical. Requires protective finish for corrosion resistance. Suitable for indoor, dry environments or when painted/coated.

EN8 (080M40): Medium carbon steel offering higher tensile strength (580-700 MPa). Good balance of strength and machinability. Suitable for structural and mechanical applications requiring enhanced durability.

EN16T (605M36T): Free-cutting medium carbon steel with improved machinability. Excellent for complex geometries and tight tolerances. Higher strength than EN1A, suitable for moderate stress applications.

High-Tensile Steels: We can manufacture connector nuts from high-strength steel materials where increased load-bearing capacity is required. Material selection based on application requirements with tensile strengths ranging from 400 MPa (mild steel) to 1200+ MPa (high-tensile alloys).

*Important Note on Nut Grades: Connector nuts at 3D length significantly exceed the dimensional parameters of standard nuts covered by ISO 898-2 (nut grades 5, 6, 8, 10, 12 for metric) or ASME/SAE standards (grades 2, 2H, 5 and 8) or BS1083 grades (A, P, R, T for imperial). These grading systems apply to standard nuts with height typically ≤0.89D. Connector nuts cannot be legitimately grade-marked using these standards.* Instead, Trojan Special Fasteners specifies the actual material used (EN1A, EN8, 303SS, 316SS, etc.) with material certificates and mechanical properties available on request.

Stainless Steel Grades

303 Stainless Steel: Free-machining austenitic stainless steel with excellent corrosion resistance. Contains sulphur for improved machinability. Suitable for most indoor and outdoor environments. Not recommended for marine use or chloride-rich environments.

304 Stainless Steel (A2): The most widely used stainless steel grade. Excellent corrosion resistance, good mechanical properties, non-magnetic (typically). Suitable for food processing, pharmaceutical, architectural, and general corrosion-resistant applications. Lower machinability than 303.

316 Stainless Steel (A4): Marine-grade stainless steel containing molybdenum (2-3%) for superior corrosion resistance, particularly against chlorides, acids, and marine environments. Essential for coastal, offshore, chemical processing, and highly corrosive applications. Excellent pitting and crevice corrosion resistance.

Duplex Stainless Steels (2205, 2507): Available on request for extreme corrosion resistance combined with high strength. Used in offshore oil & gas, chemical processing, and seawater applications.

Non-Ferrous Alloys

Brass (CZ121, CZ126): Copper-zinc alloy offering excellent machinability, electrical conductivity, and decorative appearance. Good corrosion resistance in atmospheric conditions. Commonly used in electrical, plumbing, decorative, and instrument applications. Available in various grades including free-cutting leaded brass.

Aluminium Alloys (6082-T6): Lightweight (approximately one-third the weight of steel), excellent corrosion resistance, and good machinability. Anodising available for enhanced surface properties. Ideal for aerospace, transport, weight-critical applications, and corrosive environments where magnetic properties must be avoided.

Bronze: Available on request for bearing applications, marine use, or where brass properties are insufficient. Excellent wear resistance and corrosion resistance in seawater.

Specialist Alloys

- Copper – electrical conductivity and thermal applications

- Phosphor bronze – spring characteristics and wear resistance

- High-tensile alloy steels – applications requiring enhanced strength

Surface Finishes & Protective Coatings

Surface treatments enhance corrosion resistance, improve aesthetics, provide electrical properties, and extend service life.

Zinc Plating

Bright Zinc Plating (BZP): Electroplated zinc coating (5-15 microns) providing sacrificial corrosion protection. Bright, shiny finish suitable for indoor applications or mild environmental exposure. Economical and widely specified. Salt spray resistance: 96-240 hours to red rust (depending on thickness).

Yellow Zinc Plating: Chromate passivation over zinc providing enhanced corrosion resistance and distinctive gold/yellow appearance. Salt spray resistance: 240-480 hours.

Zinc Flake Coatings (Geomet, Dacromet, KL100): Thin-film zinc-aluminium flake coating applied by dip-spin process. Exceptional corrosion resistance (>1000 hours salt spray), excellent for automotive, outdoor structural, and marine applications. No hydrogen embrittlement risk. Available in silver-grey or black finish.

Nickel Plating

Electroless or electrolytic nickel coating (5-25 microns) providing excellent corrosion and wear resistance. Maintains dimensional accuracy, provides uniform coating thickness, and offers good electrical conductivity. Suitable for hydraulic systems, electrical applications, and decorative finishes. Can be combined with PTFE for reduced friction.

Black Oxide (Black Passivate)

Conversion coating producing a black magnetite finish. Minimal dimensional change, improved oil retention, reduced light reflection, and professional appearance. Provides mild corrosion resistance and is commonly used with oil or wax topcoats. Popular for tooling, machinery, and aesthetic applications.

Phosphate Coating

Manganese or zinc phosphate conversion coating providing excellent paint adhesion, oil retention, and break-in characteristics. Used as pre-treatment for painting/powder coating or as a final finish with oil for mild corrosion resistance. Common in automotive and heavy machinery applications.

Stainless Steel Passivation

Chemical treatment removing free iron and enhancing the natural oxide layer on stainless steel surfaces. Improves corrosion resistance and provides a clean, contamination-free surface. Essential for medical, food processing, and pharmaceutical applications. Citric or nitric acid processes available.

Galvanising

Hot-dip galvanising available for larger connector nuts, providing thick zinc coating (45-85 microns) with exceptional durability and corrosion resistance. Suitable for outdoor structural applications, infrastructure, and long-term corrosion protection.

Additional Coating Options:

- Electroplating: Cadmium (aerospace), tin (electrical), silver (high conductivity)

- Mechanical plating: Zinc for larger components, no hydrogen embrittlement

- Powder coating: Decorative, available in any RAL colour

- PTFE/Teflon coating: Reduced friction, chemical resistance

- Anodising: For aluminium components in various colours

- Chrome plating: Decorative, hard chrome for wear resistance

Precision Manufacturing & Quality Standards

Thread Manufacturing Processes

Thread Tapping: Conventional tapping with high-quality HSS or carbide taps ensuring accurate thread form, pitch, and concentricity. Suitable for all materials and thread forms. Provides excellent surface finish.

Thread Milling: CNC thread milling for large diameters, interrupted threads, or where superior concentricity is essential. Allows single-pass threading and minimal tool wear.

Thread Rolling: Cold-forming process for stronger threads with enhanced fatigue resistance. Work-hardened thread flanks provide superior performance under cyclic loading.

Thread Grinding: Precision ground threads for ultra-tight tolerances, hard materials, or post-heat-treatment applications.

Thread Tolerance Classes

ISO Metric Threads:

- 6H – Standard tolerance class for general applications, easily assembled

- 5H – Medium tolerance providing good fit with reduced clearance

- 4H – Precision tolerance for close-fitting applications

- Custom tolerance classes available to drawing specifications

Unified Inch Threads:

- 2B – Standard tolerance class for UNC/UNF threads

- 3B – Precision tolerance for close-fitting applications

- Custom classes available including interference fits

BSW/BSF British Standard Threads:

- Normal tolerance class providing reliable assembly

- Close tolerance class for precision applications

- Made to BS 84, BS 93, or customer specifications

Dimensional Tolerances

- Thread pitch: ±0.02mm (metric), ±0.0005" (inch)

- Overall length: ±0.2mm standard, ±0.1mm precision

- Across flats (hex): ±0.2mm standard, ±0.1mm precision

- Outer diameter (round): h9 standard, h7/h8 precision

- Thread concentricity: 0.05mm TIR maximum

- Perpendicularity: within 0.1mm per 10mm length

Quality Assurance Procedures

- Material Verification: Mill certificates and material traceability for all batches

- Thread Inspection: GO/NO-GO thread gauges for every production batch

- Dimensional Verification: Callipers, micrometers, height gauges, CMM where required

- Torque Testing: Assembly and breakaway torque testing when specified

- Visual Inspection: 100% visual inspection for surface defects, finish quality

- Coating Thickness: X-ray fluorescence (XRF) testing of plated components

- Hardness Testing: Rockwell or Vickers hardness verification for specified grades

- Salt Spray Testing: Corrosion resistance verification per BS EN ISO 9227

- Batch Documentation: Full traceability with batch numbers and inspection records

- ISO 9001 Certified: Quality management system ensuring consistent standards

We can machine connector nuts to your dimensions, drawing or sample in a multitude of sizes, materials and finishes.

We can manufacture to the following specifications:

Material Selection Matrix

Please note we don't work with all the materials in this table

| APPLICATION ENVIRONMENT | RECOMMENDED MATERIAL | ALTERNATIVES |

|---|---|---|

| Indoor, dry, con-corrosive | EN1A with Zinc Plating | EN8 with Zinc Plating |

| Outdoor, mild weather | 303 or 304 Stainless | Zinc-Plated Steel (EN1A/EN8 etc) |

| Marine, coastal, offshore | 316 Stainless Steel | Duplex Stainless |

| Chemical Processing | 316 Stainless Steel | Monel, Hastalloy |

| Food & pharmaceutical | 304 or 316 Stainless | - |

| High temperature (>300°C) | 316 Stainless Steel | Inconel alloys |

| Electrical/Conductive | Brass (CZ121) | Copper |

| Lightweight requirement | Aluminium 6082-T6 | Titanium |

| High strength requirement | EN8, high-tensile steel | High-tensile alloys |

| Decorative/architectural | Brass, polished stainless | Aluminium anodised |

We can machine connector nuts to your dimensions, drawing or sample in a multitude of sizes, materials and finishes.

| Standard | Description |

|---|---|

| ASME/ANSI B18.2.2 | Hex coupling nuts Table 13 |

| DIN 6334 | Hex coupling nuts |

| IFI 128-2000 | Hex coupling nuts |

International Standards & Specifications

Current Active Standards for Connector Nuts

ASME B18.2.2 (2015) – Table 13: Hex Coupling Nuts

American standard specifying dimensions for hexagon coupling nuts in unified threads (#8 through 2" diameter). This standard specifically covers elongated coupling nuts (typically 3D length) and includes specifications for viewing holes, hex dimensions, and length requirements. Widely used in North American industrial and construction applications.

ASME B18.2.4.6M: Metric Hex Coupling Nuts

Metric equivalent standard specifying coupling nut dimensions in metric thread sizes for elongated connector nuts.

IFI-128 (2000): Inch Coupling Nuts

Industrial Fastener Institute standard for inch coupling nuts providing dimensional specifications and tolerances for elongated coupling nuts.

Important Note on Nut Property Standards:

ISO 898-2 (Nut Property Classes): This standard defines mechanical property classes (5, 6, 8, 10, 12) for standard metric nuts with height typically between 0.5D and 1D. Connector nuts at 3D length significantly exceed these dimensional parameters and fall outside the scope of ISO 898-2. Therefore, connector nuts cannot be legitimately grade-marked per ISO 898-2.

Imperial Nut Grades (A, P, R, T): Similarly, imperial nut grading standards (ASME B18.2.2, SAE J995) apply to standard height nuts and do not cover elongated connector nuts at 3D length.

Material Specification Approach: Trojan Special Fasteners specifies connector nuts by actual material designation (EN1A, EN8, EN16T, 303SS, 304SS, 316SS, etc.) with mechanical properties, tensile strength, and proof loads available through material certificates (EN 10204 3.1) rather than applying inapplicable nut grade markings.

Withdrawn, Obsolete, and Unratified Standards

DIN 6334: Hexagon Coupling Nuts

Status: Never officially published or ratified

Historical Context: DIN 6334 is widely referenced in catalogues and fastener literature worldwide as a standard for metric hexagon coupling nuts. However, this standard was drafted in 1943 during World War II and was never finalised or officially published by the German Institute for Standardisation (Deutsches Institut für Normung).

Industry Usage: Despite never being an official standard, DIN 6334 has been used as a de-facto reference for connector nut dimensions. Many manufacturers and suppliers continue to list "DIN 6334" connector nuts in their catalogues, either through historical precedent or as a marketing convention.

Important Note: Because DIN 6334 was never ratified, no official mechanical grade markings or property classes can be legitimately applied to connector nuts claimed to be manufactured to this standard. Additionally, as connector nuts at 3D length fall outside the scope of standard nut grading systems (ISO 898-2 for metric, ASME/SAE for imperial), grade marking is inappropriate regardless of referenced standard. *Trojan Special Fasteners always specifies the actual material used* (e.g., EN1A, EN8, 303SS, 316SS) with mechanical properties available through material certificates, rather than referencing non-existent grades.

Current Status in Germany: Germany has not replaced DIN 6334 with any equivalent standard specifically for coupling nuts, though general fastener standards exist for standard nuts.

International Obsolete and Superseded Standards Relevant to Connector Nuts

International Obsolete and Superseded Standards Relevant to Connector Nuts

| STANDARD | DESCRIPTION | STATUS | REGION | NOTES |

|---|---|---|---|---|

| DIN 6334 | Hex coupling nuts | Never published | Germany | Most commonly referenced despite never being official |

| GOST 5915-70 | Hex coupling nuts | Superseded by newer GOST editions | Russia/USSR | Older Soviet standard for elongated nuts |

Note on Standard Nut Standards:

Many international standards cover standard hexagon nuts (e.g., ISO 4032, ISO 4034, BS 916, BS 4190, DIN 934) but these apply to standard height nuts (typically 0.8D to 1D) and are not applicable to elongated connector nuts at 3D length. These standards have been excluded from this listing as they do not cover connector nut applications.

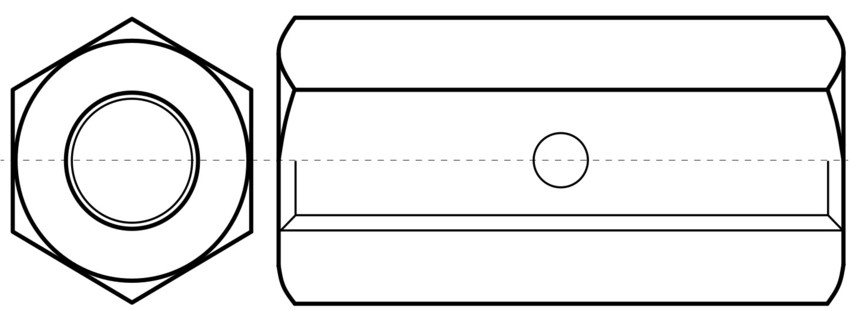

Reducing Connector Nuts & Adapter Nuts

Reducing Connector Nuts

Reducing connector nuts (also called reducing coupling nuts or step-down connectors) join threaded components of different diameters. These nuts feature a larger thread at one end and a smaller thread at the other, both typically of the same thread form (e.g., both metric or both unified).

Common Reducing Combinations:

- M20 to M16 / M16 to M12 / M12 to M10 / M10 to M8

- ½" UNC to ⅜" UNC / ¾" UNC to ½" UNC

- 1" BSW to ¾" BSW / ¾" BSW to ⅝" BSW

Design Considerations for Reducing Nuts:

Across-Flats Selection: The hex size (A/F) should be selected based on the larger thread size to ensure adequate strength and prevent distortion during installation. However, clearance constraints may require a compromise.

Thread Engagement Balance: Since thread sizes differ, ensure both ends provide adequate engagement. The smaller thread typically governs the overall strength of the assembly.

Length Calculation: Total length must accommodate full engagement on both sides. For example, M16 to M12 reducer needs minimum 16mm + 12mm = 28mm threaded length, plus transition zone.

Transition Zone: The internal transition between thread sizes should be smoothly machined to prevent stress concentrations and allow full engagement of both sides.

Adapter Nuts

Adapter nuts are connector nuts that join different thread forms or standards, allowing interconnection of incompatible threaded components.

Common Adapter Combinations:

- Metric to BSW/BSF (e.g., M16 to 5/8" BSW)

- Metric to Unified (e.g., M12 to ½" UNC)

- BSW to UNC (e.g., ¾" BSW to ¾" UNC – different pitch)

- BSPP to NPT (parallel to tapered pipe threads)

- Left-hand to right-hand thread combinations

- Fine pitch to coarse pitch conversions

Example Application – Thread Conversion:

Customer Requirement: Attach a modern metric-threaded component (M16 × 1.5) to an older machine with 11/16" BSW thread.

Trojan Solution: Manufactured custom adapter connector nut in EN16T steel with 11/16" BSW internal thread one end, M16 × 1.5 metric internal thread the other end. Hex A/F sized at 27mm for adequate strength. Delivered within 5 working days.

Result: Customer avoided expensive component replacement or modification. Simple, cost-effective, reversible solution.

Mixed-Pitch and Mixed-Direction Configurations

Fine-to-Coarse Adapters: M12 × 1.25 (fine) to M12 × 1.75 (coarse) allows fine adjustment capability whilst maintaining coarse thread strength.

Left-Hand/Right-Hand Combinations: Used in turnbuckles, tensioning systems, and anti-loosening applications where rotation in one direction tightens both connections simultaneously.

- Tensioning systems (cable and rod assemblies)

- Adjustable linkages and control rods

- Anti-vibration installations

- Turnbuckle assemblies

- Bidirectional adjustment mechanisms

Optional Features & Custom Enhancements

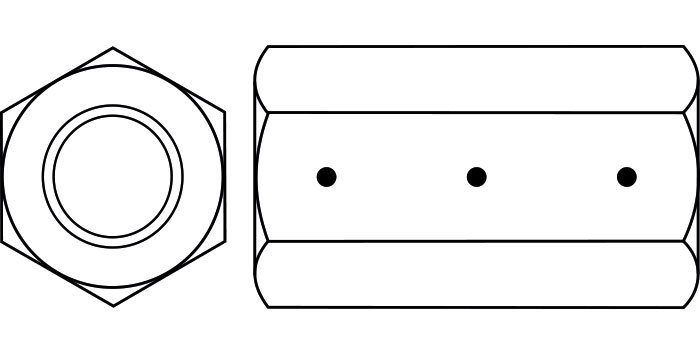

Viewing Ports and Sight Holes

Cross-drilled holes (typically 3-6mm diameter) positioned at the mid-point of the connector nut, allowing visual verification that both threaded components have fully engaged and met in the centre.

Benefits:

- Visual confirmation of proper assembly

- Quality control during installation

- Secondary function: insertion point for tommy bar or rod to aid tightening

- Prevents incomplete assembly and potential joint failure

- Specified in ASME B18.2.2 Table 13 for coupling nuts

Thread-Locking Features

Pre-Applied Patches: Factory-applied nylon or resin patches at thread entry points providing consistent prevailing torque and vibration resistance.

Tapped Grub Screw Holes: Radial holes threaded to accommodate set screws (grub screws) for positive locking against threaded rod after installation.

Deformed Thread Sections: Localised thread deformation creating interference fit and prevailing torque.

Crimped Sections: Post-assembly crimping to lock connector nut position on threaded rod.

Identification and Marking

- Laser etching: Part numbers, batch codes, customer logos, traceability information

- Stamped marking: Size, grade, material identification

- Colour coding: Paint or anodising for visual identification

- Serialisation: Unique serial numbers for critical applications

Weldable Base Ends

One end of the connector nut can be manufactured with a weldable profile (flat face, extended plain section) allowing permanent attachment to structures whilst maintaining threaded connection capability at the other end.

Anti-Rotation Features

- Serrated or knurled flanges preventing rotation in assembly

- Square or hexagonal pockets for captured installation

- Flat ground onto round profile for wrench engagement

- Pin holes for cross-pinning to prevent loosening

Precision Ground Outer Diameters

For applications requiring press-fit installation or running fits, we can precision grind the outer diameter to h6, h7, or h8 tolerance, ensuring consistent interference or clearance fits.

Applications Across Industries

Construction and Structural Engineering

- Scaffolding systems – connecting scaffold poles and framework

- Formwork tie rods – securing concrete formwork with tensioning

- Suspended ceilings – threaded rod suspension and levelling

- Curtain wall systems – facade mounting and adjustment

- Precast concrete connections – joining pre-stressed elements

- Steel structure assembly – connecting structural members

- Temporary shoring and bracing systems

- Foundation anchor rod connections

Rail, Tram, and Transport Infrastructure

- Catenary suspension systems – overhead power line support

- Rail fastening systems – securing rails to sleepers

- Platform edge barriers and gates – adjustable mounting

- Signalling equipment installations

- Track side equipment mounting

- Rolling stock component assembly

- Brake linkage and cable systems

- Bogie and suspension assemblies

Mechanical and Manufacturing Engineering

- Jigs and fixtures – adjustable workholding and positioning

- Assembly tooling – height and alignment adjustment

- Machine guards and safety enclosures

- Conveyor systems – mounting and tensioning

- Robot end-effector mounting – tool changing systems

- Precision alignment systems – optical and mechanical

- Test rigs and measurement equipment

- CNC machine tool accessories

Electrical and Electronic Systems

- Busbar systems – copper/aluminium conductor joining

- Switchgear assembly – internal component mounting

- Cable tray and support systems

- Earthing and bonding connections

- Transformer and motor mounting

- Panel mounting and spacing hardware

- Antenna mast assemblies

- Battery terminal connections

Marine and Offshore Applications

- Deck fitting installations – guardrails, cleats, bollards

- Rigging hardware – mast stays, shrouds, turnbuckles

- Pipe support systems – fuel, water, hydraulic lines

- Handrail and ladder assemblies

- Davit and crane mounting hardware

- Corrosion-resistant structural connections

- Offshore platform equipment mounting

- Gangway and access system assemblies

Plumbing and HVAC

- Pipe support brackets and clevis hangers

- Duct mounting and suspension systems

- Valve actuator linkages

- Expansion joint installations

- Strut channel (Unistrut) systems

- Seismic bracing systems

- Water heater and boiler mounting

- Flange connection assemblies

Automotive and Motorsport

- Suspension linkages and adjustment

- Engine and transmission mounting

- Roll cage construction and cross-bracing

- Brake line and cable runs

- Exhaust system mounting

- Adjustable ride height systems

- Competition vehicle assembly

- Body panel standoffs and spacers

Design and Engineering Considerations

Thread Alignment and Cross-Threading Prevention

Misaligned threads are a primary cause of connector nut installation failure. Follow these practices:

- Ensure both rods/studs are concentric and properly aligned before engaging threads

- Start threads by hand to verify correct engagement before applying torque

- Use alignment guides or bushings for long rod assemblies

- Verify thread compatibility (pitch, form, diameter) before installation

- Clean threads of dirt, paint, or debris that could prevent proper seating

- Consider self-aligning spherical washers for assemblies with angular misalignment

Load Distribution and Stress Analysis

- Calculate axial tensile loads to ensure thread engagement exceeds minimum requirements

- Consider shear loading on threads in lateral load applications

- Account for bending moments in offset or eccentric loading conditions

- Specify heavier-duty materials (class 8.8, 10.9) for high-stress applications

- Use FEA (finite element analysis) for critical or high-consequence assemblies

- Consider fatigue loading in cyclic applications requiring enhanced thread strength

Vibration and Loosening Prevention

Connector nuts in vibration-prone environments require additional measures:

Positive Locking Methods:

- Nylon insert lock nuts (not always available for custom connectors)

- Thread-locking adhesives (Loctite, Permabond – medium or high strength)

- Mechanical locking with grub screws or lock wire

- Tab washers or split pins through cross-drilled holes

- Jam nuts (secondary nut tightened against primary connector nut)

- Deformed thread locking (elliptical or crimped thread sections)

Design for Locking:

- Specify pre-applied thread-locking patches during manufacturing

- Include grub screw tapped holes in specification

- Design viewing ports as wire locking points

- Specify sufficient thread length for double-nutting technique

Torque Requirements and Installation Guidelines

Correct torque application prevents under-tightening (joint loosening) and over-tightening (thread damage, fastener failure).

Connector nuts work very differently from standard nut/bolt assemblies:

Key Differences:

- Connector nuts don't create clamping force against a surface

- They simply couple two threaded rods together

- The function is alignment and mechanical joining, not tensile preload

- Over-torquing can cause one rod to over-engage while the other under-engages

- Excessive torque can damage threads or deform thin-walled connector nuts

Appropriate Torque for Connector Nuts:

The torque requirement should be much lower - essentially:

- Hand-tight plus a small amount to ensure both rods are fully engaged

- Enough to prevent the nut backing off during service

- Typically 20-30% of standard bolt torque values, or even less

- Often just "snug-tight" is sufficient

The real installation requirement is:

Ensure both rods have correct thread engagement (verified by viewing port if fitted)

Tighten sufficiently to prevent loosening

Use thread-locking compounds for vibration resistance, NOT high torque

If high tensile forces are expected, the connector nut should be designed with adequate thread engagement, not installed with high torque

Material Compatibility in Dissimilar Metal Assemblies

Galvanic corrosion occurs when dissimilar metals are in electrical contact within an electrolyte (moisture):

Galvanic Series (Anodic to Cathodic):

- Magnesium (most anodic – corrodes first)

- Zinc

- Aluminium alloys

- Mild steel

- Cast iron

- Stainless steel 304/316

- Brass

- Copper

- Bronze (most cathodic – corrodes last)

Design Guidelines:

- Avoid large cathodic surface area coupled with small anodic area

- Use insulating washers or coatings to break electrical contact

- Select materials close together in the galvanic series

- Use sacrificial anodes or cathodic protection in critical assemblies

- Apply protective coatings to more anodic material

- Consider environmental exposure (marine environments accelerate galvanic corrosion)

Thermal Expansion Considerations

Different materials expand at different rates when subjected to temperature changes:

Coefficients of Linear Thermal Expansion (per °C):

- Aluminium: 23 × 10⁻⁶

- Brass: 19 × 10⁻⁶

- Mild Steel: 12 × 10⁻⁶

- Stainless Steel (304/316): 17 × 10⁻⁶

- Titanium: 9 × 10⁻⁶

Design Considerations:

- Allow for differential expansion in mixed-material assemblies

- Consider thermal cycling effects on preload and joint tension

- Account for expansion when calculating threaded engagement at elevated temperatures

- Specify materials with similar expansion coefficients for precision assemblies

- Use flexible joints or expansion couplings in long assemblies subject to temperature variation

Troubleshooting and Problem-Solving Guide

Problem: Connector Nut Vibrating Loose Over Time

Root Causes:

- Insufficient initial torque preload

- Vibration exceeding resistance of friction alone

- Inadequate thread engagement

- Smooth, polished threads with low friction coefficient

- Cyclic loading causing fatigue and relaxation

Solutions:

- Apply thread-locking compound (medium-strength Loctite 243 for semi-permanent, high-strength Loctie 270 for permanent)

- Specify connector nuts with factory-applied nylon patches

- Use jam nut configuration (secondary nut tightened against connector nut)

- Add cross-drilled holes for wire locking or split pin retention

- Specify grub screw tapped holes for positive mechanical locking

- Increase engagement length to increase friction resistance

- Consider deformed-thread locking nuts or crimped-thread sections

- Use spring washers or locking washers to maintain preload

Problem: Threads Not Aligning / Difficult to Start Threading

Root Causes:

- Misalignment of rods or studs being connected

- Bent or damaged threaded rods

- Paint, debris, or corrosion in threads

- Incorrect thread type or pitch

- Burrs or damage on thread entry

- Tolerance stack-up in assembly

Solutions:

- Verify thread specifications match (pitch, diameter, form) using thread gauges

- Clean all threads thoroughly with wire brush or compressed air

- Use alignment fixtures or guides to ensure rod concentricity

- Chamfer thread starts on rods to ease engagement

- Start threads by hand before applying tools to confirm correct engagement

- Inspect rods for straightness and replace bent components

- Consider using reducing connectors if thread sizes or types don't match

- Use thread-chasing taps or dies to clean damaged threads

Problem: Connector Nut Splits or Cracks During Installation

Root Causes:

- Over-tightening beyond material strength limits

- Insufficient wall thickness for applied torque

- Brittle material (hardened steel without stress relief)

- Impact loading during installation

- Cross-threading creating stress concentrations

- Incompatible material for application environment (e.g., mild steel in marine environment causing corrosion-induced cracking)

Solutions:

- Use torque wrench and follow specified torque values

- Select higher-grade material (EN8 or high-tensile steel)

- Increase hex size (A/F) for greater wall thickness

- Ensure proper thread alignment before applying torque

- Replace brittle materials with ductile alternatives

- Avoid impact wrenches on small or delicate connector nuts

- Consider stress-relieved materials for high-torque applications

Problem: Corrosion Causing Nuts to Seize

Root Causes:

- Insufficient or inappropriate surface protection

- Dissimilar metal galvanic corrosion

- Moisture and salt exposure (marine, road salt)

- Chemical exposure (acids, alkalis, industrial environments)

- Thread galling in stainless steel assemblies

Solutions:

- Specify appropriate surface finish (zinc-flake, nickel, or passivation)

- Use stainless steel 316 for marine or highly corrosive environments

- Apply anti-seize compound to threads during assembly (copper, nickel, or ceramic-based)

- Isolate dissimilar metals with coatings or insulating washers

- Use higher alloy grades (duplex stainless, Monel) for extreme environments

- Lubricate stainless steel threads to prevent galling

- Implement regular maintenance and inspection in corrosive environments

- Consider sacrificial zinc anodes in marine applications

Problem: Insufficient Thread Engagement / Connector Nut Too Short

Root Causes:

- Incorrect length specified during ordering

- Rods not meeting in middle of connector nut

- Thread runout on rods reducing effective engagement

- Standard 3D length insufficient for high-stress application

Solutions:

- Specify custom connector nut length (4D, 5D, or longer)

- Measure total required engagement: (thread engagement per side × 2) + transition zone

- Account for thread runout on rods (typically 2-3 thread pitches)

- Use engagement calculation: minimum 1× diameter per side, 1.5× for heavy-duty

- Verify rod lengths before connector nut installation

- Consider reducing connector nut if space is limited but engagement is insufficient with standard sizes

Problem: Connector Nut Difficult to Remove After Service

Root Causes:

- Corrosion bonding threads together

- Permanent thread-locking compound used inappropriately

- Thermal cycling causing galling or cold welding

- Paint or debris locking threads

- Thread damage during installation

Solutions:

- Apply penetrating oil (WD-40, PB Blaster) and allow to soak (24-48 hours for severe cases)

- Apply heat to expand connector nut (if material allows and safe to do so)

- Use impact tools to break corrosion bond (avoid on small or delicate fasteners)

- Cut connector nut with angle grinder or hacksaw if removal is essential and nut is disposable

- Prevent future issues by using removable thread-locking compounds (Loctite 243 vs 270)

- Apply anti-seize compound during installation for future removal

- Specify corrosion-resistant materials for environments requiring future disassembly

Frequently Asked Questions

1. What exactly is a connector nut, and how does it differ from a standard nut?

A connector nut is an elongated fastener with internal threads at both ends, designed specifically to join two externally threaded components (such as rods, studs, or bolts). Unlike a standard nut which threads onto a bolt or stud to create a clamping force against a surface, a connector nut creates a mechanical coupling between two male threaded components. Standard nuts are typically shorter (height approximately equal to thread diameter), whilst connector nuts are significantly longer – commonly 3 times the thread diameter (3D) – to provide adequate thread engagement for both connecting components. The external geometry can be hexagonal (like standard nuts) for tool engagement, or round/cylindrical where rotation capability or compact diameter is required.

2. What are all the different names for connector nuts?

Connector nuts are known by numerous names depending on industry, region, and specific application. Common alternative names include: coupling nuts, joining nuts, extension nuts, long nuts, studding connectors, rod coupling nuts, threaded couplers, hex coupling nuts, barrel nuts (when round profile), threaded sleeves, stud connectors, and rod joiners. In some contexts, they may also be called threaded adapters when joining different thread types. The term "coupling nut" is particularly common in North America (ASME standards), whilst "connector nut" is widely used in British and European contexts. Despite the varying terminology, all these names refer to the same basic fastener concept: an elongated, internally threaded component joining two male threaded items.

3. Which external profiles are available for connector nuts, and how do I choose the right one?

Connector nuts are manufactured in several external profiles, each suited to different applications:

Hexagon (Hex) Profile: The most common profile, featuring six flats for engagement with standard spanners, sockets, or adjustable wrenches. Hex connectors provide excellent torque transmission, are easy to install with standard tools, and offer good resistance to rotation once tightened. Choose hex profiles for general applications, structural assemblies, and where high installation torque is required.

Round (Cylindrical) Profile: Smooth, cylindrical external surface without flats. Round connectors are ideal for applications requiring rotation (turnbuckles, adjustable linkages), reduced external diameter for tight clearances, aesthetic or decorative installations, or where tools cannot be accommodated (internal assemblies). They may be installed using strap wrenches, pin spanners engaging viewing holes, or knurled sections for hand-tightening.

Double-Flat Profile: Features two parallel flats on opposite sides of a round body. This design provides a compact spanner engagement point whilst maintaining a smaller overall diameter than hex profiles. Useful where hex size would be too large but some torque capacity is needed.

Square Profile: Four-flat profile offering anti-rotation capability when fitted into square recesses or slots. Square connector nuts are rare and typically used in specialist applications requiring specific torque characteristics or where hexagonal profiles don't suit the assembly geometry.

Custom Profiles: We manufacture custom external geometries including knurled surfaces for hand-tightening, serrated anti-rotation profiles, precision ground diameters for press-fit applications, flanged designs combining connector and washer functions, and multi-diameter stepped profiles for complex assemblies.

4. What thread types and standards can Trojan Special Fasteners manufacture?

We manufacture connector nuts with virtually any thread form specified, including:

ISO Metric Threads: Coarse pitch (M3 to M52), fine pitch, ultra-fine pitch, specified to ISO 724 and ISO 965

Unified Inch Threads: UNC (coarse), UNF (fine), UNEF (extra-fine), UNS (special) per ANSI/ASME B1.1, sizes #8 through 2.25"

British Standard Whitworth (BSW) and British Standard Fine (BSF): Imperial threads per BS 84, sizes 2BA through 2" diameter

British Association (BA) Threads: Precision threads for instruments and electronics (2BA, 1BA, 0BA, etc.)

British Standard Pipe Threads: BSPP (parallel) and BSPT (tapered) per BS 21

Buttress, Acme, and Trapezoidal Threads: For power transmission and specialist applications

Custom and Proprietary Threads: Manufactured to customer drawings, specifications, or sample threads

We also produce mixed thread configurations (reducing and adapter nuts) combining different thread types, sizes, pitches, or directions (left-hand/right-hand combinations) in a single connector nut.

5. Can connector nuts be manufactured with left-hand threads?

Yes, absolutely. Left-hand threaded connector nuts are routinely manufactured for applications requiring reverse thread operation. We produce:

Both ends left-hand threaded: For applications where reverse (anti-clockwise) rotation is required to tighten

One end left-hand, one end right-hand: Essential for turnbuckle assemblies, tensioning systems, and adjustable linkages where rotation in one direction simultaneously tightens both connections

Mixed size and direction: Combining different thread diameters with opposite hand directions (e.g., M12 LH to M16 RH)

Left-hand threads are particularly useful in preventing loosening due to rotational forces (e.g., on left-side vehicle wheel studs), in bidirectional adjustment mechanisms, and in safety-critical applications where conventional right-hand loosening must be prevented.

Sizing, Dimensions, and Length

6. How do I determine the correct length for a connector nut?

Correct length calculation ensures adequate thread engagement for joint strength and reliability. Follow this methodology:

Step 1 – Determine Required Engagement per Side:

- Standard applications: 1.0 × nominal thread diameter per side

- Heavy-duty or high-stress: 1.5 × nominal thread diameter per side

- Critical or fatigue-loaded: 2.0 × nominal thread diameter per side

Step 2 – Account for Thread Runout:

Add 2-3 thread pitches per rod to account for incomplete thread formation at the end of threaded rods

Step 3 – Add Central Transition Zone (if required):

5-10mm unthreaded central section (optional but common in standard connectors)

Step 4 – Calculate Total Length:

Total length = (Engagement Side A) + (Engagement Side B) + (Transition zone if required) + (Runout allowance)

Example Calculation – M16 Heavy-Duty Application:

- M16 nominal diameter = 16mm

- Heavy-duty engagement = 1.5 × 16 = 24mm per side

- Thread runout allowance = 3 × pitch (M16 coarse pitch = 2.0mm) = 6mm per rod

- Central transition zone = 8mm

- Total minimum length = 24 + 24 + 6 + 6 + 8 = 68mm

- Practical specified length = 70mm

For reducing connector nuts, calculate engagement separately for each thread size and use the larger value to ensure adequate strength.

7. What does "3D" mean when describing connector nut length?

"3D" is standard fastener industry terminology meaning the length of the connector nut equals 3 times the nominal thread diameter (3 × Diameter). This is a common default length providing good thread engagement balance. For example:

- M10 connector nut, 3D length = 3 × 10mm = 30mm total length

- M20 connector nut, 3D length = 3 × 20mm = 60mm total length

- ½" connector nut, 3D length = 3 × 0.5" = 1.5" total length

The 3D convention provides approximately 1× diameter thread engagement per side with a small central unthreaded transition zone. However, 3D is not mandatory – we manufacture connector nuts in any length from 1D (very short) to 10D or longer for specialist applications. Always specify the exact length required rather than relying on 3D as default if your application has specific engagement requirements.

8. What is the standard hex size (across flats) for connector nuts?

Hex sizes for connector nuts generally follow the same standards as hex bolts and nuts for equivalent thread sizes. Standard metric hex dimensions (across flats, A/F) are listed in the detailed table under "Hex Profile Connector Nuts" section above. However, custom hex sizes can be specified:

Reasons for Custom Hex Sizes:

- Reducing connector nuts may need hex size based on larger thread diameter

- Clearance constraints requiring smaller hex dimensions

- Higher torque requirements needing larger hex for increased strength

- Matching existing tooling or assembly equipment

- Aesthetic or design standardisation across product range

Always specify the desired across-flats dimension if critical to your application. We can manufacture non-standard hex sizes or even combine different across-flats with specific thread sizes.

9. Can I order connector nuts shorter or longer than standard 3D length?

Yes, absolutely. We manufacture connector nuts in any length to suit your specific requirements. Common custom lengths include:

- Ultra-short (1D to 2D): For space-constrained applications where full engagement isn't required or where additional structure provides load distribution

- Standard-plus (4D to 5D): For increased thread engagement in high-stress applications or where thread quality on rods is uncertain

- Extra-long (6D to 10D+): For specialist applications requiring extended reach, long adjustment ranges, or where connector nut serves as structural spacer as well as mechanical coupling

Simply specify the total required length in millimetres or inches when ordering. We recommend providing either the total overall length or the desired thread engagement per side – our engineering team can advise on optimal dimensions for your application.

Materials and Mechanical Properties

10. Which materials are most commonly used for connector nuts, and how do I choose?

Material selection depends on multiple factors including strength requirements, environmental conditions, weight constraints, electrical properties, and cost:

Mild Steel (EN1A): Most economical option for general-purpose indoor applications. Good machinability and weldability. Requires protective finish (zinc plating) for corrosion resistance. Tensile strength ~400 MPa. Suitable for non-structural, light-to-medium duty applications where environmental exposure is minimal.

Medium Carbon Steel (EN8, EN16T): Higher tensile strength than mild steel (580-700 MPa vs 400 MPa). Better suited to structural and mechanical applications requiring enhanced durability and load-carrying capacity. Good machinability with improved wear resistance. Cost-effective balance of performance and price.

High-Tensile Alloy Steel: Specified where high clamping forces, tensile strength, or proof loads are critical. High-tensile steels offer 800-1200+ MPa tensile strength. Essential for safety-critical, high-stress, or dynamic loading applications. Requires careful selection of surface treatments.

Stainless Steel 303: Free-machining austenitic stainless offering excellent corrosion resistance with superior machinability compared to 304/316. Tensile strength 500-700 MPa. Ideal for moderate corrosion environments, indoor/outdoor use, food processing (non-acidic), and applications requiring both corrosion resistance and complex machining features.

Stainless Steel 304 (A2): Most widely specified stainless grade. Excellent general corrosion resistance, good mechanical properties (500-700 MPa tensile strength), typically non-magnetic, and suitable for food, pharmaceutical, architectural, and general outdoor use. More corrosion-resistant than 303 but slightly harder to machine.

Stainless Steel 316 (A4): Marine-grade stainless containing 2-3% molybdenum for superior resistance to chlorides, salt water, and acids. Tensile strength 500-700 MPa. Essential for coastal, offshore, marine, chemical processing, and highly corrosive industrial environments. Significantly better pitting and crevice corrosion resistance than 304.

Brass (CZ121): Excellent machinability, good corrosion resistance in atmospheric conditions, and superior electrical conductivity. Tensile strength ~350-450 MPa. Attractive golden appearance suitable for decorative applications. Common in electrical, plumbing, musical instruments, and aesthetic installations. Non-magnetic and non-sparking.

Aluminium (6082-T6): Lightweight (approximately 1/3 the weight of steel), excellent corrosion resistance, and good machinability. Tensile strength ~310 MPa. Anodising available for enhanced surface properties and colour options. Ideal for aerospace, transport, weight-critical applications, and where magnetic properties must be avoided.

11. What mechanical properties and strength specifications are available?

Connector nuts at 3D length significantly exceed the dimensional parameters of standard nuts and fall outside the scope of standard nut grading systems:

ISO 898-2 (Metric Nut Grades 5, 6, 8, 10, 12): Applies to standard nuts with height typically 0.5D to 1D. Not applicable to connector nuts at 3D.

BS1083 Imperial Nut Grades (A, P, R, T): Similarly apply to standard height nuts, not elongated connector nuts.

*Trojan's Approach:* We specify connector nuts by material designation with mechanical properties:

Steel Materials:

- EN1A: Tensile strength ~400 MPa, general purpose mild steel

- EN8: Tensile strength 580-700 MPa, medium carbon structural steel

- EN16T: Tensile strength exceeding EN8, medium carbon alloy steel

- High-tensile alloys: Tensile strength 800-1200+ MPa for demanding applications

Stainless Steel Materials:

- 303SS: Tensile strength 500-700 MPa, free-machining, corrosion-resistant

- 304SS (A2): Tensile strength 500-700 MPa, excellent general corrosion resistance

- 316SS (A4): Tensile strength 500-700 MPa, marine-grade with superior chloride resistance

Brass and Aluminium:

- Brass CZ121: Tensile strength 350-450 MPa, excellent machinability

- Aluminium 6082-T6: Tensile strength 310 MPa, lightweight

Material certificates (EN 10204 3.1) providing chemical composition, mechanical properties, tensile strength, and proof loads are available on request. This material-based specification approach provides clear, verifiable mechanical properties without applying inapplicable nut grade markings.

*Important Note:* Because connector nuts cannot be legitimately grade-marked per standard nut grading systems, be cautious of suppliers claiming "Grade 8" or "Class 10" connector nuts – these grade markings are not applicable to elongated connector nuts and may indicate misunderstanding of standards or misleading marketing.

12. What's the difference between 304 and 316 stainless steel, and when should I choose each?

Both 304 and 316 are austenitic stainless steels (non-magnetic, excellent corrosion resistance, good formability), but they differ significantly in composition and performance:

304 Stainless Steel (A2):

- Composition: 18% chromium, 8% nickel, balance iron (18-8 stainless)

- Corrosion Resistance: Excellent in atmospheric and mildly corrosive environments

- Applications: Indoor, outdoor (non-marine), food processing, pharmaceutical, architectural

- Cost: Lower cost than 316

- Limitations: Susceptible to chloride pitting and crevice corrosion in marine/coastal environments

316 Stainless Steel (A4):

- Composition: 16-18% chromium, 10-14% nickel, 2-3% molybdenum, balance iron

- Corrosion Resistance: Superior resistance to chlorides, acids, salt water, and industrial chemicals

- Applications: Marine, coastal, offshore, chemical processing, road salt exposure, swimming pools

- Cost: 20-40% more expensive than 304

- Advantages: Molybdenum addition significantly improves pitting and crevice corrosion resistance

Decision Guide:

Choose 304 for:

- General outdoor use (non-coastal)

- Food processing and pharmaceutical (non-acidic)

- Architectural and decorative applications

- Indoor corrosive environments (mild chemicals)

- Cost-sensitive projects where marine exposure is not a factor

Choose 316 for:

- Marine, coastal, and offshore applications (salt water, sea spray)

- Chemical processing with chlorides or acids

- Road salt exposure (winter maintenance areas)

- Pulp and paper industry

- Petroleum refining and petrochemical

- Swimming pool and spa equipment

- Any application where 304 has previously experienced pitting or corrosion

Surface Finishes and Coatings

13. Why are surface finishes important, and how do I choose the right one?

Surface finishes serve multiple critical functions:

Corrosion Protection: Prevents oxidation (rust) and material degradation, extending service life and maintaining joint integrity

Aesthetic Appearance: Provides professional finish, colour coding, or decorative qualities

Electrical Conductivity: Certain finishes (tin, silver) enhance conductivity; others (anodising, powder coating) provide insulation

Friction Modification: Can increase or decrease coefficient of friction affecting installation torque and locking characteristics

Lubricity: Reduces galling and seizing, particularly important in stainless steel assemblies

Chemical Resistance: Protects against specific chemicals, solvents, or aggressive environments

Finish Selection Decision Matrix

| ENVIRONMENT | RECOMMENDED FINISH | ALTERNATIVE | NOTES |

|---|---|---|---|

| Indoor, dry, heated | Bright zinc, black oxide | None (for stainless) | Cost-effective protection |

| Outdoor, temperate climate | Zinc-flake (Geomet), yellow zinc | 303/304 passivated | 500-1000 hour salt spray |

| Marine, coastal | 316ss passivated preferred | Zinc-flake on steel | Material choice critical |

| High humidity, indoor | Nickel plating, zinc-flake | 304ss passivated | Prevents rust staining |

| Chemical exposure | 316ss, nickel plating | PTFE coating | Depends on chemical type |

| High temperature (>200°C) | 316ss, passivated, none | Dry film lubricants | Most platings unsuitable |

| Electrical conductivity | Tin plating, silver plating | Nickel plating | Low contact resistance |

| Decorative/architectural | Polished stainless, brass | Powder coating (colours) | Appearance priority |

| Food contact | 304/316 passivated | Electropolished stainless | FDA/EU compliant |

14. What is zinc-flake coating (Geomet/Dacromet), and when should it be used?

Zinc-flake coating is an advanced corrosion protection system consisting of thin, overlapping zinc and aluminium flakes in an inorganic binder, applied by dip-spin process:

Key Advantages:

- Exceptional corrosion resistance: typically >1000 hours neutral salt spray to red rust

- Very thin coating (6-10 microns) with minimal dimensional effect

- No hydrogen embrittlement risk (unlike electroplated zinc)

- Excellent adhesion and uniform coverage even in recessed areas

- High temperature resistance (up to 300°C for some variants)

- Can be top-coated for enhanced corrosion protection or appearance

Common Brand Names:

- Geomet (NOF Metal Coatings)

- Dacromet (Daiwa/Henkel)

- KL100 (various suppliers)

- Delta-Protekt, Delta-Tone (Dörken)

Typical Applications:

- Automotive chassis components

- Construction and infrastructure fasteners exposed to road salt

- Wind turbine assemblies (corrosive, high-vibration environment)

- Agricultural equipment (moisture, fertiliser exposure)

- Outdoor electrical installations

- Rail and transport infrastructure

Finish Options:

- Silver-grey (standard)

- Black (with carbon addition)

- Coloured top coats (for identification or aesthetics)

Choose zinc-flake coating when long-term corrosion protection is essential, particularly in road salt, marine, or industrial environments, and when the component is steel (not suitable for stainless steel, brass, or aluminium).

15. Should I use thread-locking compounds with connector nuts?

Thread-locking compounds (anaerobic adhesives such as Loctite) provide vibration resistance and prevent loosening without requiring additional locking hardware. However, proper selection and application are critical:

When to Use Thread-Locking Compounds:

- Vibration-prone environments (machinery, vehicles, transport)

- Applications where access for re-tightening is difficult or impossible

- Assemblies subject to thermal cycling

- Fine-pitch threads more susceptible to loosening

- Where jam nuts or mechanical locking is impractical

Loctite Grade Selection:

Low-Strength (Loctite 222, Purple): Removable with hand tools. Use for small threads (M6 and below), brass or aluminium fasteners, or where frequent disassembly is anticipated.

Medium-Strength (Loctite 243, Blue): Most versatile grade. Removable with standard tools. Use for general-purpose vibration resistance on M6-M20 fasteners where future removal may be required. Disassembly with standard tools at normal torque.

High-Strength (Loctite 270, Red): Permanent assembly. Requires heat (250°C) or specialised tools for removal. Use only where disassembly is not anticipated or where maximum vibration resistance is essential. Suitable for M6-M20.

Application Guidelines:

- Clean and degrease threads thoroughly before application (thread-lock requires clean, oil-free surfaces)

- Apply 2-3 drops to male thread before engaging connector nut

- Alternatively, apply to first few threads inside connector nut

- Clamp time: 5-15 minutes; full cure: 24 hours

- Do not over-apply – excess compound can contaminate adjacent components

- For pre-applied patches, specify during manufacturing for consistent, controlled application

Cautions:

- Stainless steel threads require activator/primer for proper curing (Loctite 7649, 7471)

- Not suitable for pure oxygen systems, strong oxidisers, or chlorine (fire/explosion risk)

- High-strength grades may make future disassembly extremely difficult

- Consider future maintenance requirements before specifying permanent thread-locking

Manufacturing and Custom Capabilities

16. What is the smallest and largest connector nut Trojan can manufacture?

We manufacture connector nuts across an extensive size range:

Smallest Sizes:

- Metric: M3 (3mm diameter) and above

- Imperial: 2BA (British Association, approximately 2.8mm)

- Unified: #8 (approximately 4.2mm diameter)

Very small connector nuts (M3-M5, 2BA-BA0, #8-#10) are typically manufactured in limited lengths due to wall thickness constraints and practical tool engagement requirements.

Largest Sizes:

- Metric: M52 (52mm diameter) as standard capacity; larger sizes possible by enquiry

- Imperial: 2" BSW/BSF (50.8mm diameter)

- Unified: 2¼" UNC/UNF (57mm diameter)

For diameters exceeding our standard range, please enquire. Very large connector nuts may require alternative manufacturing methods (weld fabrication, casting with machined threads) depending on material, quantity, and dimensional requirements.

Length Capacity:

- Minimum: Approximately 1D (one diameter) for short coupling applications

- Maximum: Limited primarily by material availability and machine capacity – connector nuts up to 500mm+ length can be manufactured

- Standard: 3D (three times diameter) is most common

17. Can you manufacture connector nuts to my drawing or sample?

Absolutely. We specialise in custom connector nut manufacturing to customer specifications. You can provide:

Engineering Drawings: PDF, DWG, DXF, or other CAD formats with dimensions, tolerances, thread specifications, material, and finish requirements

Samples: Physical samples of existing connector nuts (we'll reverse-engineer dimensions and thread specifications)

Sketches: Hand-drawn or simple dimensioned sketches for straightforward designs

Verbal Specifications: For standard configurations, you can specify thread size, length, profile (hex/round), material, and finish verbally or by email

Our Engineering Process:

- Review your specification and confirm all critical dimensions, tolerances, thread types

- Highlight any potential manufacturing challenges or opportunities for optimisation

- Provide detailed quotation including unit price, tooling costs (if applicable), and lead time

- Request approval before commencing manufacture

- Manufacture to specification with full quality control and inspection

- Provide batch certification, material certificates, or inspection reports if required

18. What are typical lead times and minimum order quantities?

Lead times and minimum quantities vary based on complexity, material availability, and current production schedule:

Standard Configurations (Metric Hex Connector Nuts in Common Sizes, Mild Steel or 303SS):

- Prototype/Sample Quantities (1-10 pieces): 3-5 working days

- Small Batch (10-100 pieces): 5-10 working days

- Production Quantities (100-1000+ pieces): 10-15 working days

- Large Volume (1000+ pieces): 15-20 working days or by agreement

Custom or Complex Configurations:

- First-time custom designs: 10-15 working days (includes engineering review)

- Non-standard materials (exotic alloys, special steels): Add 2-4 weeks for material procurement

- Special finishes (zinc-flake, nickel plating): Add 5-7 days for external processing

- Very large diameters (M36+) or very long lengths (300mm+): Add 1-2 weeks

Minimum Order Quantities:

- No strict minimum – we manufacture one-off prototypes to full production runs

- For highly complex or time-intensive designs, minimum order values may apply to ensure cost-effectiveness

- Volume pricing available for larger quantities – request quotation for specific requirements

Expedited Service:

- Rush orders can sometimes be accommodated – please enquire and explain your timeline

- Express machining available for urgent requirements (additional charges apply)

19. Can you provide material certificates and inspection documentation?

Yes, comprehensive documentation can be provided for quality assurance and traceability:

Material Certificates (Mill Certs):

- EN 10204 3.1 certificates providing chemical composition and mechanical properties

- Traceability from material batch to finished product

- Standard for aerospace, medical, nuclear, and high-specification projects

Dimensional Inspection Reports:

- First Article Inspection (FAI) documenting dimensions of first production piece

- Batch inspection reports confirming compliance with drawing specifications

- Full dimensional layout for critical or high-value projects

Surface Finish Testing:

- Coating thickness reports (XRF testing of plating)

- Salt spray test certifications (ASTM B117, ISO 9227)

- Adhesion and appearance verification

Thread Inspection Documentation:

- Thread gauge inspection records (GO/NO-GO results)

- Optical thread measurement for critical applications

- Thread class and tolerance verification

Batch Traceability:

- Unique batch numbers linking finished products to raw material, process parameters, inspection results

- Essential for recalls, failure analysis, or warranty claims

Documentation requirements should be specified at quotation stage to ensure accurate pricing and lead time calculation.

Technical Applications and Problem-Solving

20. Can connector nuts be used in high-temperature environments, and what are the limitations?

Yes, connector nuts can be designed and manufactured for elevated temperature service, but material selection and design considerations are critical:

Temperature-Resistant Materials:

Up to 200°C: Zinc-plated mild steel (zinc melts at 420°C but effectiveness decreases above 200°C), 303/304 stainless steel, brass

Up to 400°C: 304 stainless steel, 316 stainless steel (passivated or bare)

Up to 600°C: 316 stainless steel, 310 stainless steel (high-temperature grade), Inconel 600

Up to 1000°C: Inconel 625/718, Nimonic alloys, high-temperature nickel alloys

Design Considerations for High-Temperature Applications:

- Thermal Expansion: Calculate differential expansion between connector nut and threaded rods – different materials expand at different rates. Allow clearance or select materials with similar thermal expansion coefficients.

- Thread Clearance: Increase thread clearance (e.g., 6H to 7H) to accommodate thermal expansion and prevent seizing at elevated temperatures.

- Surface Finish: Most plating unsuitable above 200-250°C. Use bare stainless steel with passivation, dry film lubricants, or high-temperature anti-seize compounds.

- Lubrication: Standard oils and greases breakdown at high temperatures. Use ceramic-based anti-seize (copper, nickel, graphite-based) or molybdenum disulphide dry lubricants.

- Mechanical Properties: Tensile strength and proof loads decrease at elevated temperatures. Verify material strength at operating temperature and increase engagement length if necessary.

- Oxidation: Even corrosion-resistant materials can oxidise at very high temperatures. Consider Inconel or other high-temperature alloys for extreme environments.

Recommended Approach:

Consult with our engineering team providing operating temperature, duration of exposure (continuous vs intermittent), environment (air, vacuum, combustion gases, chemicals), and expected thermal cycling. We'll recommend appropriate materials, tolerances, surface treatments, and design modifications.

21. How do I prevent galvanic corrosion when using connector nuts with dissimilar metals?

Galvanic corrosion occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (moisture, salt solution, etc.), causing accelerated corrosion of the more anodic (reactive) material. Prevention strategies include:

Material Selection Strategy:

- Choose metals close together in the galvanic series (minimises potential difference)

- Use connector nut material that matches or is more noble (cathodic) than the rods being connected

- Example: Stainless steel connector nut with stainless steel rods – no galvanic couple

- Example: Brass connector nut with copper rods – minimal potential difference

Electrical Isolation Methods:

- Insulating washers (nylon, PTFE, composite) breaking electrical contact

- Non-conductive sleeves or bushings

- Coating one or both metal surfaces to prevent direct contact

Protective Coatings:

- Apply barrier coating (paint, powder coating, anodising) to more anodic component

- Ensure coating is continuous without scratches or gaps

- Re-coat after installation if coating is damaged during assembly

Environmental Control:

- Eliminate or reduce moisture and electrolyte exposure

- Use sealants, encapsulation, or protective housings

- Maintain dry environment where practical

Sacrificial Anodes:

- In marine or buried applications, install sacrificial zinc anodes

- Anodes corrode preferentially, protecting the assembly

Design Considerations:

- Avoid large cathode (noble metal) area coupled with small anode (active metal) area – this accelerates corrosion of the anode

- Equal or larger anode area is preferable

- Example: Large aluminium structure with small stainless fasteners is poor design; large stainless structure with small aluminium fasteners is less problematic

Common Problematic Combinations to Avoid (unless precautions taken):

- Aluminium connector nut with stainless steel rods (aluminium will corrode rapidly)

- Mild steel connector nut with copper or brass rods in moisture

- Zinc-plated steel connector nut with stainless rods (zinc corrodes but may be acceptable as sacrificial protection)

22. What should I do if threads won't engage properly or I experience cross-threading?

Cross-threading is a common installation problem causing thread damage, weakened joints, and potential failure. Follow this troubleshooting procedure:

Immediate Actions if Resistance is Felt During Installation:

- STOP immediately – do not force threading

- Back out the connector nut completely

- Inspect both male threads and internal threads for damage, burrs, debris

Verification Checks:

- Thread Specification Match: Verify thread size, pitch, and form using thread gauges or callipers. Ensure M12 × 1.75 isn't being threaded into M12 × 1.5, for example.

- Thread Class Compatibility: Ensure male thread class (e.g., 6g) is compatible with internal thread class (e.g., 6H)

- Thread Condition: Look for damaged threads, bent rods, paint or debris in threads, corrosion or rust

Corrective Actions:

- Clean Threads: Use wire brush, compressed air, or solvent to remove paint, dirt, oil, cutting fluid

- Repair Minor Damage: Run thread-chasing die over male threads or thread-chasing tap through connector nut to restore thread form

- Align Components: Use alignment fixtures, templates, or guides to ensure rods are concentric and square

- Chamfer Thread Starts: File or grind a slight chamfer on male thread entry to ease initial engagement

- Lubricate: Apply light oil or anti-seize to threads to reduce friction and ease starting

Installation Technique:

- Start by Hand: Always start threading by hand for at least 3-4 full rotations to confirm correct engagement

- Feel for Smoothness: Threading should feel smooth and consistent – any binding, clicking, or irregular resistance indicates cross-threading

- Support Both Rods: Prevent misalignment by supporting both threaded rods so they don't deflect during connector nut installation

- Use Correct Tools: Apply spanners or sockets only after confirming correct thread engagement by hand

If Cross-Threading Has Occurred:

- Remove connector nut carefully

- Inspect threads on both components for damage (flattened peaks, torn roots, metal slivers)

- Minor damage: Clean with thread chaser or run a tap/die through

- Severe damage: Cut off damaged section and re-thread, or replace damaged rod

- Replace connector nut if internal threads are damaged beyond repair

23. What is thread galling, and how can it be prevented in stainless steel connector nuts?

Thread galling (also called cold welding or seizing) is a severe form of adhesive wear occurring primarily in stainless steel fasteners. During installation, high friction and pressure cause metal-to-metal contact points to weld together momentarily, then tear away, progressively destroying the thread form and eventually seizing the fastener solid.

Why Stainless Steel is Susceptible:

- Poor lubricity (high coefficient of friction compared to steel)

- Work-hardening characteristics – stainless hardens when deformed, increasing friction

- Lack of protective oxide at high-friction contact points

- Self-mating stainless (304 to 304, 316 to 316) is worst case

Symptoms of Galling:

- Progressively increasing installation torque (should be consistent)

- Rough, binding, or jerky feel during threading

- Metallic squeaking or grinding sounds

- Inability to back out fastener after partial installation

- Visible thread damage, metal pickup, welding spots

Prevention Strategies:

Primary Prevention – Lubrication:

- Always lubricate stainless steel threads before assembly

- Use anti-seize compounds: copper-based (most common), nickel-based (food industry), ceramic-based (high temperature)

- Alternative: Molybdenum disulphide (moly) grease, PTFE-based lubricants, wax-based thread compounds

- Apply to male threads before engaging connector nut

Material Selection:

- Use nitrided stainless steel (surface hardened)

- Specify free-machining 303 stainless (easier machining, slightly better lubricity than 304/316)

- Consider dissimilar materials: stainless steel connector nut with plated steel rods (reduces self-mating friction)

Thread Class Selection:

- Specify looser thread class: 7H or 8H internal threads (instead of 6H) provide clearance reducing contact pressure

- Avoid tight tolerance classes (4H/5H) for stainless steel self-mating assemblies

Surface Treatment:

- Silver plating over stainless steel threads (excellent lubricity)